What is a seamless carbon steel tee?

Solutions

What is a seamless carbon steel tee?

What is a seamless carbon steel tee?

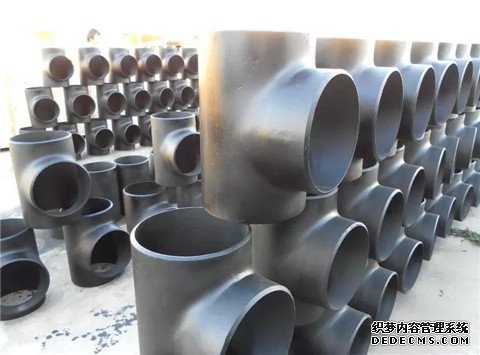

In order to ensure the quality of carbon steel seamless three-way products, standardize the manufacturing process, and strictly manage the process, this process is specially formulated. This process is applicable to the seamless three-way machining process of carbon steel produced by our company. According to the standard GB/T 12459-2005 “Steel Butt-weld Seamless Pipe Fittings” GB/T 8163-1999 “Seamless Steel Pipe for Transfer Fluids” and the manufacturing process, the seamless three-way steel manufacturing process is as follows: → Cutting → Pressing → Heat Treatment → Groove → Derusting → Shaping → Brushing → Marking → Inspection Storage.

1, under the material: first to the production of the three links to the standard material off. Cut the seamless tube into segments. Diameter: diameter +30% Use sawing machine, flame for cutting. The length of blanking should meet the technical requirements. The finished pipe section is grinded to flatten both ends. Ensure that the two sides face the vertical deviation of the axis and the parallelism of the two ends.

2. Derusting: Put the cut pipe into the derusting equipment for tumbling and grinding to reach the purpose of derusting.

3, kneading: Put the tube except good rust into the mold, and fill water from the outside of the piston of the mold to the pipe, so that the pipe will converge to the center under the effect of pressure. There is a hole under the mold. This hole is a release point for the pipe to be kneaded, and then it is intended to do three links.

4. Trimming: At this moment, the carbon steel three-way link can only be called “two links,” which means that the two ends are open, and the center three links are also just a raised straight section. Cut up the raised straight pipe section, and then grind and machine the groove of the product. In this way, the three links will be formed. Groove equipment uses ordinary lathes. The burr produced by the groove should be polished. The groove angle is 37.5±2.5°. The surface of the Tee should be de-rusted prior to painting to remove rust and increase paint adhesion. As far as conditions permit, the shot blasting rust remover is used for blasting rust removal. Rust removal effect to remove floating rust, to see the metal color is appropriate.

5, heat treatment: The basic shape of the three-way into the large annealing furnace when the line smolder, let it natural cooling and then removed. Steel seamless tee extrusion should be heat treated, in order to eliminate the stress generated during cold extrusion. Heat to about 750 °C, constant temperature for a certain period of time (constant temperature is 1h per 25mm wall thickness, and shall not be less than 15min), with the furnace cooling to below 400 °C after the natural cooling furnace.

6. Descaling: Put the fired three links into the derusting equipment again. Excluding the oxide scale and the scale, the intact product is completed.

7. Identification: Finished carbon steel seamless tee should be durable and clearly marked. If the labeling method is required by the parties, it shall be stipulated by the demander; if there is no stipulation, the product performance shall be implemented according to the standard. Before inspection of the three-way storage, the quality inspector shall inspect the geometric size and appearance. The internal and external surfaces of the tee must not be markedly scratched by grooves or collisions, and there should be no defects such as cracks, scabs, folds, and delaminations. Geometry checking is performed according to the GB/T 12459-2005 standard. The inspection shall be completed with the "Three-way Inspection Record" (YGBG-06). After passing the three-pass inspection, it can be stored in the warehouse. It should be placed neatly in the designated stock area according to the specification and model, and be protected from the defacement and collision.

Pipe Fittings Co., Ltd. specializes in the production of various accessories for petrochemical pipelines such as elbows, tees, reducers, flanges and other pipe fittings. The company's equipment is advanced and complete, with multiple pushers and cold draws. Machines, hydraulic presses, vehicles, drills and other machining equipment and heat treatment and various welding equipment, a variety of raw material physics and chemistry analyzers and various testing equipment, can produce a variety of high school and low pressure elbow, different diameter pipe, three links, large Bend, caps and so on, advanced technology, strong forces; has the ability to undertake pipe fittings, flanges and other pipe fittings series, and can process non-standard products according to the requirements of users. KunHuan Pipe Fittings adopts garden mode management in environmental planning, adopts humanized management concept in the management of garden mode, makes customers and employees feel the same warmth of home;

while improving the plant capacity, appearance, and factory wind, it is developing vigorously. Corporate culture, strive to build a company full of vitality into a new type of company that can continuously improve and have a modern civilization. For many years, KunHang has always adhered to the principle of “Continuously satisfying customers' needs and providing customers with quality products and services”. It has won high praise from users and more products have been used in many groups such as Angang, Handan Iron and Steel, Lanzhou Gas, and Beijing Gas. The company's key projects; while the company by virtue of good reputation, the Chinese Ministry of Chemical Industry identified as fixed-point enterprises, the provincial Agricultural Bank of AAA-level enterprises, the provincial Bureau of Industry and Commerce, the contract and trustworthy enterprise, here, the pipe fittings company employees sincerely serve domestic and foreign users, Sincerely welcome customers to visit our factory to negotiate business and cooperate together for a better future!

while improving the plant capacity, appearance, and factory wind, it is developing vigorously. Corporate culture, strive to build a company full of vitality into a new type of company that can continuously improve and have a modern civilization. For many years, KunHang has always adhered to the principle of “Continuously satisfying customers' needs and providing customers with quality products and services”. It has won high praise from users and more products have been used in many groups such as Angang, Handan Iron and Steel, Lanzhou Gas, and Beijing Gas. The company's key projects; while the company by virtue of good reputation, the Chinese Ministry of Chemical Industry identified as fixed-point enterprises, the provincial Agricultural Bank of AAA-level enterprises, the provincial Bureau of Industry and Commerce, the contract and trustworthy enterprise, here, the pipe fittings company employees sincerely serve domestic and foreign users, Sincerely welcome customers to visit our factory to negotiate business and cooperate together for a better future!

上一篇:Application of high pressure elbow in piping system

下一篇:GB 9711 standard spiral steel pipe

What is a seamless carbon steel tee?:

New Products

- ELBOWS

- Seamless Steel Large Bore Cap

- 45 Deg Steel Elbow

- SEAMLESS CARBON STEEL BUTT-WELD PIPE FITTINGS

- ASTM A234 Knee

- A105 carbon steel socket Elbow

- How complex is the type distribution of carbon steel elbow?

- Pipe flanges fitting relationship

- butt welding stub end

- Nickel & Nickel Alloy 20 Elbow

- Alloy Steel Pipe Fitting

- GB 9711 standard spiral steel pipe

Contact Us

- Longtaidi Pipe fitting co.,ltd

- Add: Mengcun County, Cangzhou City, Hebei Province. China

- www.lordtk.com

- [email protected]

- [email protected]

- Tel:0086-317-6817153

Hot Products

- steel elbow fitting

- welding neck flange

- Lap Joint Flange

- cs elbow

- elbow:GOST17375 ST35.8 WPHY42 - 12 inch

- straight tee

- Carbon steel elbow definition and Category

- Stainless Steel Con Reducer,Ecc Reducer

Quickly Find Pipe Tee

-

Flange

-

welding flange

-

welding neck flange

-

large diameter flange

-

carbon steel flange

-

stainless steel flange

| © 2010 - 2011 Longtaidi Pipe fitting CO., LTD.