Difference Between Schedule 40 VS Schedule 80 Steel Pipe

Difference Between Schedule 40 VS Schedule 80 Steel Pipe

As an engineering researcher with expertise in materials sciences and mechanical systems, let me begin by explaining the schedule designation system for pipes. The “schedule” refers to the wall thickness standards set by governing bodies like ASME and ASTM. Higher schedule numbers indicate thicker pipe walls able to withstand greater pressures and loads.

Schedule 40 pipe has relatively thin walls, making it suitable for low pressure applications under 400 PSI such as water, air and gas lines. It is commonly used for standard residential and commercial plumbing. The thinner material makes it lighter and less expensive than higher schedule options.

Moving up to Schedule 80, this designation requires much thicker pipe walls in order to meet the standards. Specifically, Schedule 80 piping must have a minimum wall thickness around 25-30% greater than Schedule 40 of the same diameter.

This thicker construction gives Schedule 80 several important advantages. Firstly, it increases the maximum working pressure rating to around 800 PSI, allowing use in higher pressure systems like compressed air. Secondly, the more robust walls can withstand higher compression and tension loads if used in structural support applications.

However, with 25-30% more steel required per length, Schedule 80 also brings higher material and shipping costs. It is typically only specified when the pressures and loadings necessitate the extra wall thickness from both safety and performance standpoints.

In summary, the key differences are:

- Wall thickness – Schedule 80 walls are noticeably thicker

- Pressure rating – Schedule 80 can withstand 800 PSI vs 400 PSI for 40

- Strength – 80 is stronger and stiffer for its diameter

- Cost – 80 piping requires more steel, making it higher priced

I hope this overview of Schedule 40 vs 80 piping standards has been helpful! Please let me know if you have any other questions.

Here are the main advantages of using Schedule 80 steel pipes in structural support applications:

- Higher strength and stiffness – The thicker walls of Schedule 80 pipe make it more rigid and able to resist greater forces than thinner-walled Schedule 40 or lighter tubes. This is crucial for supporting heavy loads in structures.

- Increased load bearing capacity – Tests have shown Schedule 80 pipe can bear approximately 25-30% higher loads than Schedule 40, due to the substantial wall thickness. This directly enhances its feasibility as a structural member.

- Greater burst pressure resistance – The thicker walls give Schedule 80 a higher tolerance against accidental internal over-pressurization, making it safer to use as a load bearing column. The greater wall thickness acts as a pressure vessel.

- Reduced risk of buckling or kinking – Schedule 80’s extra material results in a stouter, less compressible pipe less prone to inward buckling or kinking under high axial loads or impacts. This enhances structural integrity over the long term.

- Superior resistance to dents and dings – Dents posing risks of weakness and failure are less likely to penetrate completely through the thick walls of Schedule 80 piping, absorbing impacts well for durability in tough conditions.

- Simpler welding – The walls are less prone to burning, bending or warping issues during fabrication since heat dissipates faster through the pipe thickness.

In summary, the key advantage stems from maximum strength to weight obtained through schedule standards, translating to higher load capacity, longer lifespan and safety as a structural element. Let me know if any part requires more elaboration!

4 comments

Franci

2024年5月19日 at am3:02

What is the difference between Schedule 40 and Schedule 80 steel pipe?

Ronsun2023

2024年5月19日 at am11:45

The main differences between these two options are wall thickness, ID, and weight. Schedule 80 pipe is thicker than schedule 40 pipe due to schedule 80 pipe’s wall measurements, smaller inside diameter, and higher weight.

Stephensnund

2024年6月3日 at pm3:13

What is the difference between Schedule 40 and Schedule 80 steel pipe?

Ronsun2023

2025年3月28日 at pm9:52

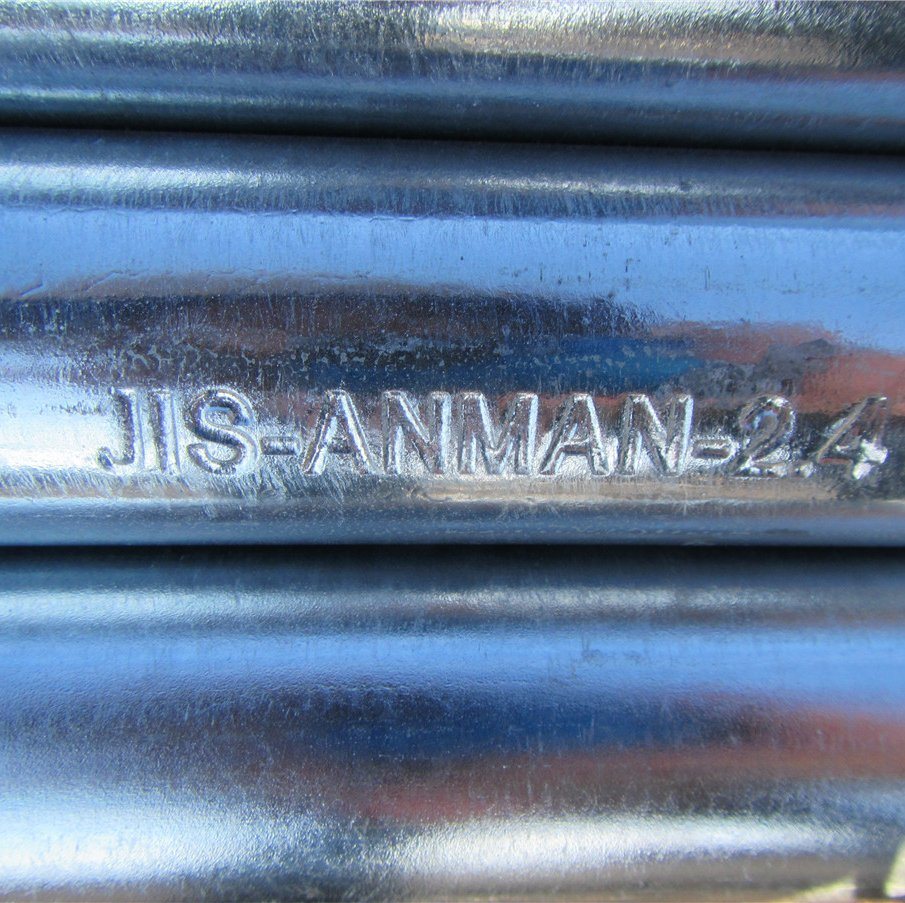

ANSI Pipe Schedules | How to Use a Pipe Schedule Chart

Schedule 40 and schedule 80 are two of the most commonly used ANSI pipe schedules. The main differences between these two options are wall thickness, ID, and weight. Schedule 80 pipe is thicker than schedule 40 pipe due to schedule 80 pipe’s wall measurements, smaller inside diameter, and higher weight.