API 5CT P110 Casing Tubing: A Comprehensive Guide

API 5CT P110 Casing Tubing: A Comprehensive Guide

Introduction

API 5CT P110 casing tubing is an essential component in the oil and gas industry. It is used to provide structural integrity to the wellbore and transport oil and gas from the source rock to the wellhead. In this comprehensive guide, we will explore the specifications, dimensions, and uses of API 5CT P110 casing tubing. We will also discuss the different types of connections, ends, and couplings associated with this product.

Specifications and Dimensions

API 5CT P110 casing tubing is available in various sizes and grades. The outer diameter of the casing pipe ranges from 4 1/2 inches to 20 inches (114.3mm to 508mm), while the wall thickness varies depending on the size. The standard casing sizes are 4 1/2 inches to 20 inches, and the thread types include buttress thread casing, long round thread casing, and short round thread casing.

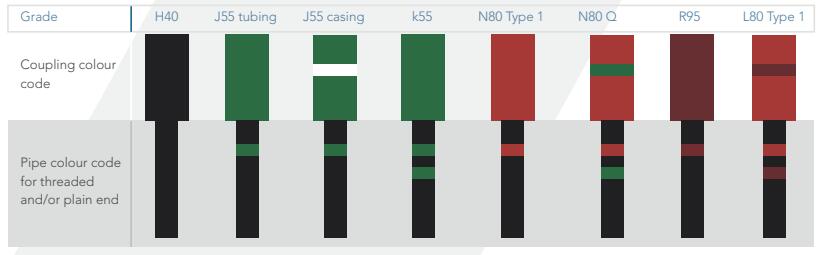

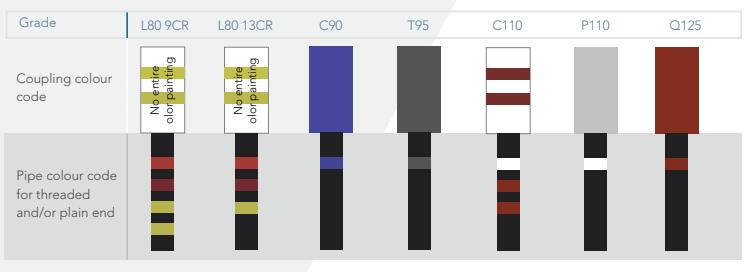

The length of the casing pipe is categorized into three ranges: R1, R2, and R3. R1 has a length range of 6.10-7.32 meters, R2 has a length range of 8.53-9.75 meters, and R3 has a length range of 11.58-12.8 meters. The steel grades available for casing and tubing include J55, K55, N80-1, N80-Q, L80, and P110.

Connection Types, Ends, and Couplings

API 5CT P110 casing tubing utilizes different connection types, ends, and couplings to ensure proper installation and functionality. The most common connection type for casing is the BTC (Buttress Thread and Coupling) connection. BTC connections have a buttress thread design and provide excellent sealing and structural integrity.

Other connection types for P110 casing pipes include LC (Long Round Thread) and SC (Short Round Thread). Premium connections like HYD (Hydraulic) are also available, which offer gas-tight sealing and enhanced performance. Customized connection threads can be provided based on client requirements.

P110 tubing connections have two main types: EUE (External Upset End) and NU (Non-Upset End). EUE connections have an external upset with a larger diameter and thickness than the tubing body. NU connections, on the other hand, have the same diameter and thickness as the tubing body.

Dimensions and Tolerances

API 5CT P110 casing pipes have specific length ranges and tolerances. The length ranges for R1, R2, and R3 are as follows:

- R1: 6.10-7.32 meters

- R2: 8.53-9.75 meters

- R3: 11.58-12.8 meters

The outer diameter tolerance for P110 casing pipes depends on the size. For pipes below 4-1/2 inches, the tolerance is +/- 0.79mm or 0.031 inch. For pipes equal to or above 4-1/2 inches, the tolerance is +1% and -0.5% of the pipe diameter. The wall thickness tolerance is 12.5%.

Imperfections in P110 casing pipes have specific limits. The maximum permissible depth of linear imperfections, both external and internal, is 12.5% of the wall thickness. However, if required, a 5% limit can be adopted for P110 grade.

Octal: A Reliable Supplier

When it comes to sourcing API 5CT P110 casing and tubing, Octal is a reputable supplier in the industry. Octal offers a wide range of P110 casing and tubing options, manufactured through seamless or ERW (Electric Resistance Welding) processes. The outer diameter options range from 2-3/8 inches to 20 inches, with various thicknesses available.

Octal provides different coupling threads, including BTC, LTC (Long Thread and Coupling), STC (Short Thread and Coupling), and premium connection threads. The length options include R1, R2, R3, and customized lengths to meet specific project requirements.

FAQ (Frequently Asked Questions)

Q1: What is the purpose of API 5CT P110 casing tubing?

API 5CT P110 casing tubing is used to provide structural integrity to the wellbore and transport oil and gas from the source rock to the wellhead.

Q2: What are the different connection types for P110 casing pipes?

The different connection types for P110 casing pipes include BTC (Buttress Thread and Coupling), LC (Long Round Thread), SC (Short Round Thread), and premium connections like HYD (Hydraulic).

Q3: What are the length ranges for API 5CT P110 casing tubing?

The length ranges for API 5CT P110 casing tubing are categorized into three options: R1, R2, and R3. R1 has a length range of 6.10-7.32 meters, R2 has a length range of 8.53-9.75 meters, and R3 has a length range of 11.58-12.8 meters.

Q4: What are the dimensions and tolerances for P110 casing pipes?

The dimensions and tolerances for P110 casing pipes include the outer diameter tolerance and the wall thickness tolerance. The outer diameter tolerance depends on the size of the pipe, while the wall thickness tolerance is 12.5%.

Q5: Where can I source API 5CT P110 casing and tubing?

Octal is a reliable supplier of API 5CT P110 casing and tubing. They offer a wide range of options, including different sizes, grades, connection types, and lengths to meet specific project requirements.

Conclusion

API 5CT P110 casing tubing plays a crucial role in the oil and gas industry, providing structural integrity and facilitating the transportation of oil and gas from the source rock to the wellhead. With its various specifications, dimensions, connection types, and tolerances, P110 casing tubing offers versatility and reliability in wellbore applications.

When sourcing API 5CT P110 casing and tubing, it is essential to choose a reputable supplier like Octal, who can provide high-quality products and customized solutions. By understanding the specifications and requirements of P110 casing tubing, you can ensure the success and efficiency of your oil and gas operations.

Remember, API 5CT P110 casing tubing is not just a component; it is a critical element that contributes to the overall performance and safety of oil and gas wells. Choose wisely and invest in the best quality products for your projects.

Click here to learn more about API 5CT P110 casing tubing and its applications.

Disclaimer: The information provided in this article is for informational purposes only and should not be considered as professional advice. Always consult with industry experts and adhere to relevant regulations and standards.