UNS S32750 stainless steel pipe is a super duplex grade that offers exceptional corrosion resistance, high strength, and durability. Its chemical composition, including elements such as chromium, nickel, and molybdenum, contributes to its unique properties. With a yield strength of ≥ 550 MPa and a tensile strength of ≥ 750 MPa, UNS S32750 stainless steel pipe can withstand high levels of stress and pressure. Its wide range of applications includes oil and gas, chemical processing, and marine industries.

Blog » Stainless Steel & Alloy Steel Pipes | 2PE 3PE coated pipe | Pipe Fittings - Pipeline Technology R&D Factory

API-5CT P110 casing pipes are an essential component in the oil and gas industry for casing wells. Their high yield strength, corrosion resistance, and excellent mechanical properties make them suitable for withstanding the demanding conditions encountered in drilling operations. By adhering to the API 5CT standard, these pipes ensure the integrity and efficiency of oil and gas wells, contributing to the overall success of the industry.

Titanium and titanium alloy pipes, manufactured according to ASTM B861, ASTM B862, and ASTM B338, offer exceptional properties and advantages for various industries. Their corrosion resistance, high strength, lightweight nature, and other unique characteristics make them ideal for applications in aerospace, chemical processing, medical, oil and gas, and many other sectors. By adhering to the specified standards and following proper fabrication and installation procedures, the performance and longevity of titanium and titanium alloy pipes can be maximized.

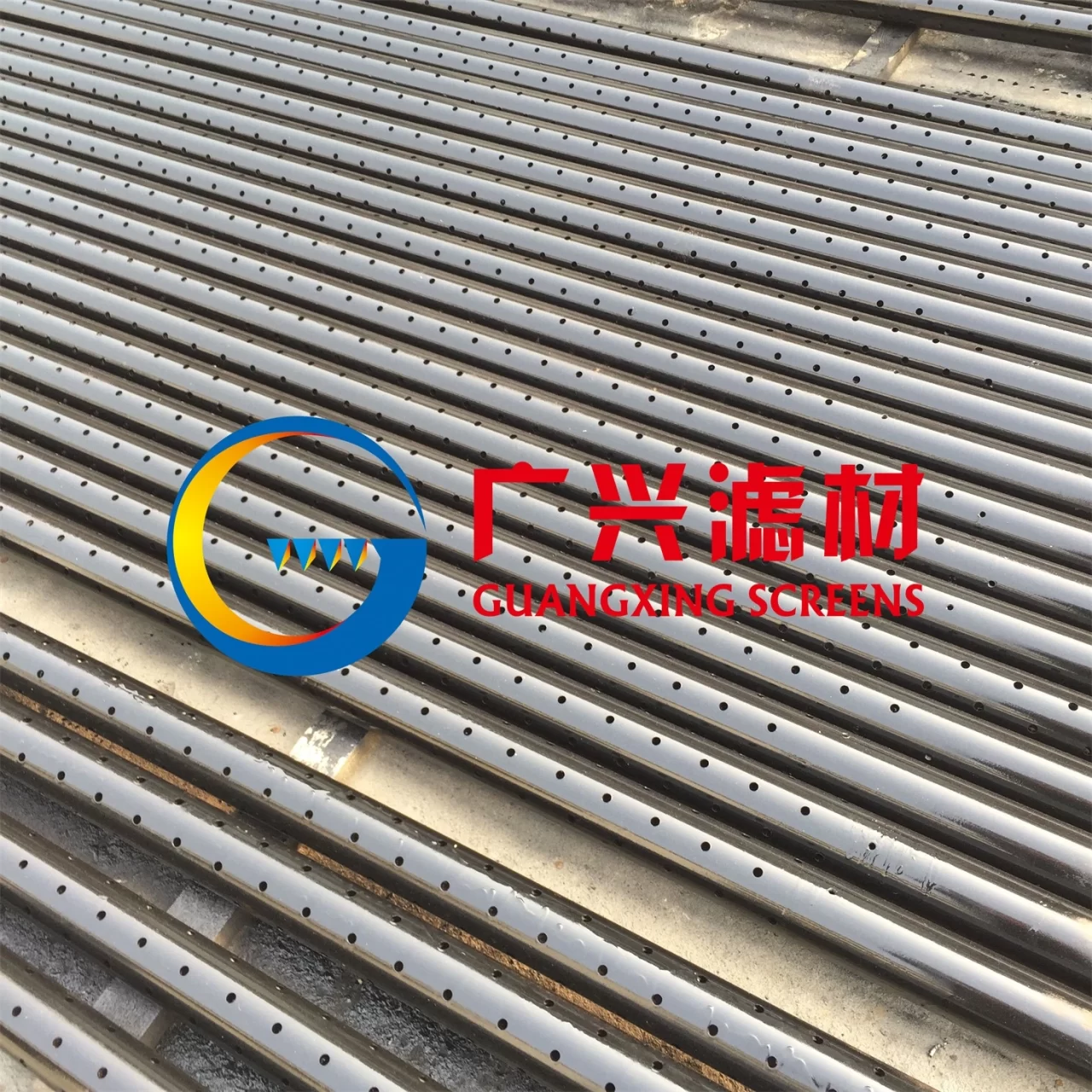

This in-depth article explores the metallurgical properties and perforation techniques leveraging J55/K55/N80 casing materials, quantifying 20% production gains through superior strength, wear resistance, and durability maintaining long-term conductivity in unconventional wells.

Hastelloy B-2 is a versatile alloy known for its exceptional corrosion resistance properties in challenging environments, making it a preferred choice for various industrial applications where resistance to reducing environments is crucial.

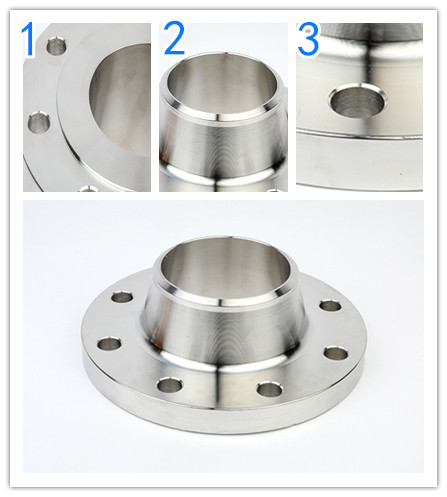

By adding a high amount of metals such as chromium and molybdenum to the 2507 Material, Duplex 2507 Spectacle Bind Spacer Ring becomes extremely resistant to uniform corrosion or General Corrosion, when exposed to environments that contain organic acids like acetic and acetic formic acid. Further, ANSI B16.5 UNS S32750 Flange exhibits excellent resistance to inorganic acids as well, especially in the presence of media that could contain chlorides. Although the ASTM A182 F53 Pipe Flange can be used in dilute hydrochloric acid, exposure to concentrated hydrochloric acid must be avoided. Due to the low carbon content of Duplex Flange, there is a low risk or minimal risk of the occurrence of carbide precipitation at the grain boundaries during heat treatment.

JIS G3461 Carbon Steel Tubes is used for exchanging heat on the inside and outside of the tube, such as water tubes, smoke tubes, superheater tubes and air preheater tubes of the boiler, and heat exchanger tubes,condenser tubes and catalyser tubes used in chemical and petroleum industries. It is not applicable to the steel tubes for heating furnace and steel heat exchanger tubes for low temperature service. Grade:G3461 STB340 (STB35), G3461 STB410(STB42), G3461 STB510 (STB52) Outer Dimensions: 19.05mm – 168.3mm Wall Thickness:2.0mm – 14 mm Length: max 19000mm

Stainless steel forged butt weld neck flanges are essential components in industrial piping systems. Their strength, durability, and leak-proof design make them suitable for a wide range of applications in various industries. By understanding their features, specifications, and applications, you can make informed decisions when selecting and installing these flanges. Remember to consult industry standards and guidelines for proper installation and maintenance procedures. With the right knowledge and expertise, you can ensure the integrity and efficiency of your piping system with stainless steel forged butt weld neck flanges.

Difference Between EN39 & BS1139 Galvanized Steel Pipe

Introduction

EN39 and BS1139 are two different standards that govern the manufacturing and specifications of galvanized steel pipes. While both standards focus on galvanized steel pipes used in scaffolding applications, there are some key differences between EN39 and BS1139 galvanized steel pipes. In this article, we will explore these differences to help you understand which standard is most suitable for your specific requirements.

EN39 Galvanized Steel Pipe

EN39 is a European standard that specifies the requirements for galvanized steel pipes used in scaffolding applications. It covers the dimensions, mechanical properties, and technical conditions of the pipes. EN39 galvanized steel pipes are known for their high strength, durability, and corrosion resistance.

The key features of EN39 galvanized steel pipes include:

- Corrosion Resistance: EN39 galvanized steel pipes are coated with a layer of zinc, providing excellent corrosion resistance. This makes them suitable for outdoor applications where they are exposed to harsh weather conditions.

- High Strength: EN39 galvanized steel pipes are manufactured using high-quality steel, ensuring their structural integrity and high load-bearing capacity. They can withstand heavy loads and provide a safe working platform for scaffolding systems.

- Easy Installation: EN39 galvanized steel pipes are designed with standardized dimensions, making them easy to install and connect. They can be easily cut, threaded, and joined using various fittings and connectors.

- Compliance with European Standards: EN39 galvanized steel pipes comply with the European standards for scaffolding applications, ensuring their quality and safety.

BS1139 Galvanized Steel Pipe

BS1139 is a British standard that specifies the requirements for galvanized steel pipes used in scaffolding applications. It covers the dimensions, mechanical properties, and technical conditions of the pipes. BS1139 galvanized steel pipes are widely used in the construction industry for scaffolding systems.

The key features of BS1139 galvanized steel pipes include:

- Corrosion Resistance: BS1139 galvanized steel pipes are coated with a layer of zinc, providing excellent corrosion resistance. This makes them suitable for outdoor applications where they are exposed to moisture and other corrosive elements.

- High Strength: BS1139 galvanized steel pipes are manufactured using high-quality steel, ensuring their structural integrity and high load-bearing capacity. They can withstand heavy loads and provide a safe working platform for scaffolding systems.

- Easy Installation: BS1139 galvanized steel pipes are designed with standardized dimensions, making them easy to install and connect. They can be easily cut, threaded, and joined using various fittings and connectors.

- Compliance with British Standards: BS1139 galvanized steel pipes comply with the British standards for scaffolding applications, ensuring their quality and safety.

Differences Between EN39 and BS1139 Galvanized Steel Pipe

While both EN39 and BS1139 galvanized steel pipes are used in scaffolding applications and share many similarities, there are some key differences between the two standards:

- Geographical Scope: EN39 is a European standard, while BS1139 is a British standard. This means that EN39 galvanized steel pipes are more commonly used in European countries, while BS1139 galvanized steel pipes are prevalent in the United Kingdom and other countries that follow British standards.

- Dimensional Differences: EN39 and BS1139 have slight differences in their dimensional requirements. These differences include variations in pipe diameter, wall thickness, and length. It is important to consider these dimensional variations when selecting the appropriate standard for your scaffolding project.

- Certification and Compliance: EN39 and BS1139 have different certification and compliance requirements. EN39 galvanized steel pipes must meet the European standards for scaffolding applications, while BS1139 galvanized steel pipes must adhere to the British standards. It is crucial to ensure that the pipes you choose comply with the relevant standards and have the necessary certifications.

- Availability: The availability of EN39 and BS1139 galvanized steel pipes may vary depending on your location. If you are in Europe, EN39 galvanized steel pipes may be more readily available, while BS1139 galvanized steel pipes may be easier to find in the United Kingdom and other countries that follow British standards.

Conclusion

EN39 and BS1139 are two widely recognized standards for galvanized steel pipes used in scaffolding applications. While both standards offer corrosion resistance, high strength, and easy installation, there are some differences in their dimensional requirements, certification, and availability. It is important to consider these factors and choose the standard that best suits your specific requirements and complies with the relevant regulations in your region. Consulting with industry experts and suppliers can help you make an informed decision and ensure the success of your scaffolding project.

Remember, EN39 galvanized steel pipes are a reliable and versatile choice for various applications. Their corrosion resistance, durability, and ease of installation make them an excellent option for construction projects and industrial applications.