Schedule 80 piping exhibits clear structural superiority versus Schedule 40 through its 25-30% thicker walls, translating to higher strength, stiffness, load tolerance, deflection resistance and durability in demanding applications. Its robustness and performance make it the standard choice for structural pipe supports.

Pipe Technology » Stainless Steel & Alloy Steel Pipes | 2PE 3PE coated pipe | Pipe Fittings - Pipeline Technology R&D Factory

Black steel pipe and galvanized steel pipe have different properties and strengths, so it is important to understand their characteristics before comparing their strength. Black steel pipe, also known as plain carbon steel pipe, is made from untreated steel without any protective coating. It is typically used in applications where corrosion resistance is not a major concern. Black steel pipe is known for its strength and durability, making it suitable for various industrial applications such as plumbing, construction, and structural support. On the other hand, galvanized steel pipe is coated with a layer of zinc to provide protection against corrosion. The zinc coating acts as a barrier between the steel pipe and the surrounding environment, preventing rust and corrosion. Galvanized steel pipe is commonly used in outdoor applications or environments with high moisture levels, such as water supply systems and outdoor structures.

Carbon steel pipe and black steel pipe are often used interchangeably, but there are some key differences between the two. Composition: Carbon Steel Pipe is made up of carbon as the main alloying element, along with other elements such as manganese, silicon, and sometimes copper. This composition gives carbon steel pipe its strength and durability. On the other hand, black steel pipe is a type of carbon steel pipe that has not undergone any additional surface treatment or coating. Surface Finish: The most apparent difference between carbon steel pipe and black steel pipe is the surface finish. Carbon steel pipe has a dark, iron oxide coating called mill scale, which forms during the manufacturing process. This mill scale gives carbon steel pipe its black appearance. In contrast, black steel pipe has a plain, uncoated surface. Corrosion Resistance: Carbon steel pipe is susceptible to corrosion due to its iron content. However, the mill scale coating on carbon steel pipe provides some level of protection against corrosion, especially in indoor or dry environments. On the other hand, black steel pipe is more prone to corrosion since it lacks any protective coating. Therefore, black steel pipe is not recommended for use in areas exposed to moisture or corrosive elements.

Based on the information provided, the ASME B 36.10 and B 36.19 standards define the dimensions and weight of welded and seamless steel pipes. These standards provide guidelines for the manufacturing and installation of steel pipes in various industries, including oil and gas, petrochemical, and power generation. ASME B 36.10 specifies the dimensions and weights of welded and seamless wrought steel pipes. It covers pipes ranging from NPS 1/8 (DN 6) through NPS 80 (DN 2000) and includes various wall thicknesses and schedules. The dimensions covered include outside diameter, wall thickness, and weight per unit length.

In industrial and residential applications, it is frequently necessary to join different types of metals. These connections can be between stainless steel and carbon steel, two of the most commonly used materials in piping systems. This article will walk you through the process of connecting stainless steel pipe to carbon steel pipe fittings, the challenges involved, and how to overcome them.

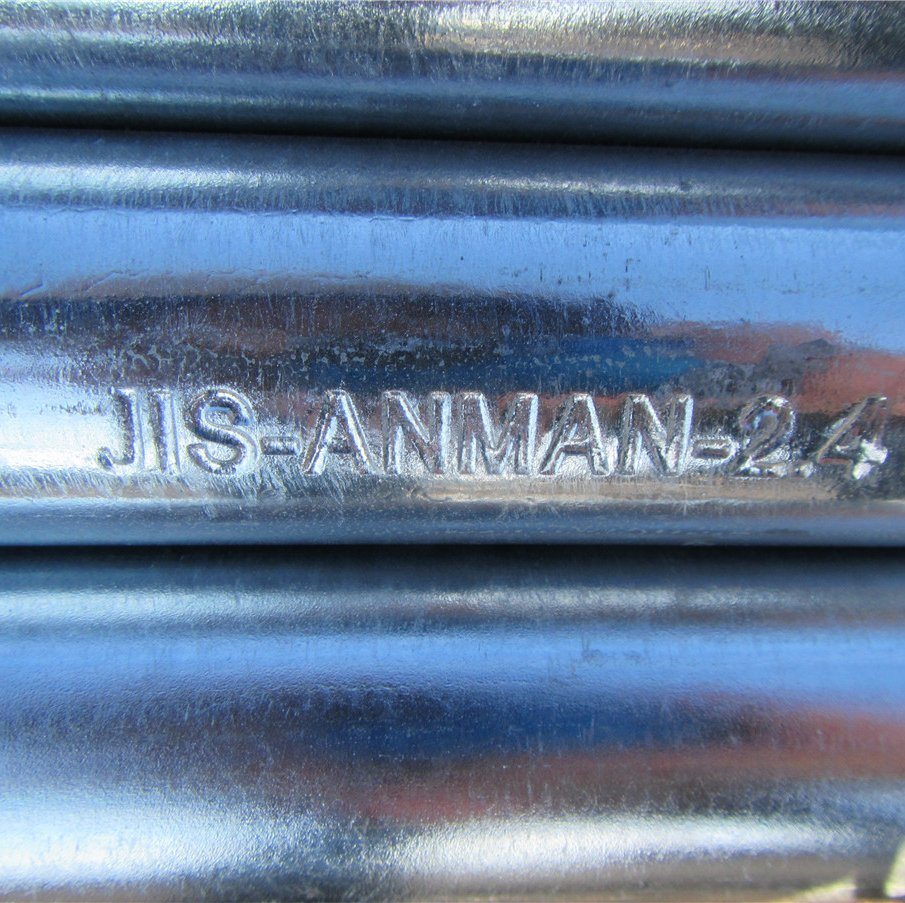

Brand new Chinese GB Japanese JIS American ASTM German DIN steel pipe standard comparison table

A hard, mechanically strong top coating for all fusion bonded epoxy pipeline corrosion protection coatings. It is applied to the base coating to form a tough outer layer that is resitant to gouge, impact, abrasion and penetration. abter steel is specifially designed to protect the primary corrosion coating from damage during pipeline directional drilling applications, bored, river crossing and installation in rough terrain.

Black Steel Pipe and Galvanized Steel Pipe are both types of steel pipes used in various applications, and their main difference lies in their coating and resistance to rust and corrosion.