Is black steel pipe stronger than galvanized steel pipe ?

Carbon steel pipe and black steel pipe are two common types of steel pipes used in various industries and applications. While they may appear similar in appearance, there are some key differences between these two types of pipes. Let’s explore the dissimilarities and understand when each is typically used.

- Composition:

Carbon Steel Pipe: Carbon steel pipe is primarily made of carbon and iron, with small amounts of other elements such as manganese, silicon, and copper. The carbon content in carbon steel pipe generally ranges from 0.18% to 0.30%, which gives it its strength and hardness.

Black Steel Pipe: Black steel pipe gets its name from the dark, protective iron oxide coating on its surface, which gives it a black appearance. It is composed mainly of iron and carbon, with no additional elements. The absence of alloying elements makes it less resistant to corrosion but more affordable than carbon steel pipe.

- Manufacturing Process:

Carbon Steel Pipe: Carbon steel pipes are manufactured by either seamless or welded methods. Seamless pipes are produced by piercing a solid billet and extruding it to the desired length and thickness. Welded pipes, on the other hand, are made by rolling and welding a flat steel plate or strip into a cylindrical shape.

Black Steel Pipe: Black steel pipes are typically made using the electric resistance welding (ERW) process. This involves passing a high-frequency electric current through the edges of a steel strip to heat and fuse them together. The resulting seam is then cooled and smoothed, creating a continuous pipe.

- Surface Finish:

Carbon Steel Pipe: Carbon steel pipe usually has a plain or slightly rough surface finish. It lacks the dark coating present on black steel pipes.

Black Steel Pipe: Black steel pipe has a characteristic dark, rough, and scaly appearance due to the iron oxide coating present on its surface. This coating provides some degree of protection against corrosion.

- Corrosion Resistance:

Carbon Steel Pipe: Carbon steel pipe is vulnerable to corrosion due to its higher carbon content. However, it can be protected from corrosion through various methods such as applying coatings, using corrosion-resistant alloys, or implementing cathodic protection.

Black Steel Pipe: Black steel pipe is less resistant to corrosion compared to carbon steel pipe. The iron oxide coating on its surface provides limited protection against rust and other forms of corrosion. Therefore, it is often used in applications where corrosion resistance is not a primary concern.

- Applications:

Carbon Steel Pipe: Carbon steel pipe is widely used in various industries, including oil and gas, construction, automotive, and manufacturing. It is suitable for transporting fluids and gases, structural applications, and high-temperature environments.

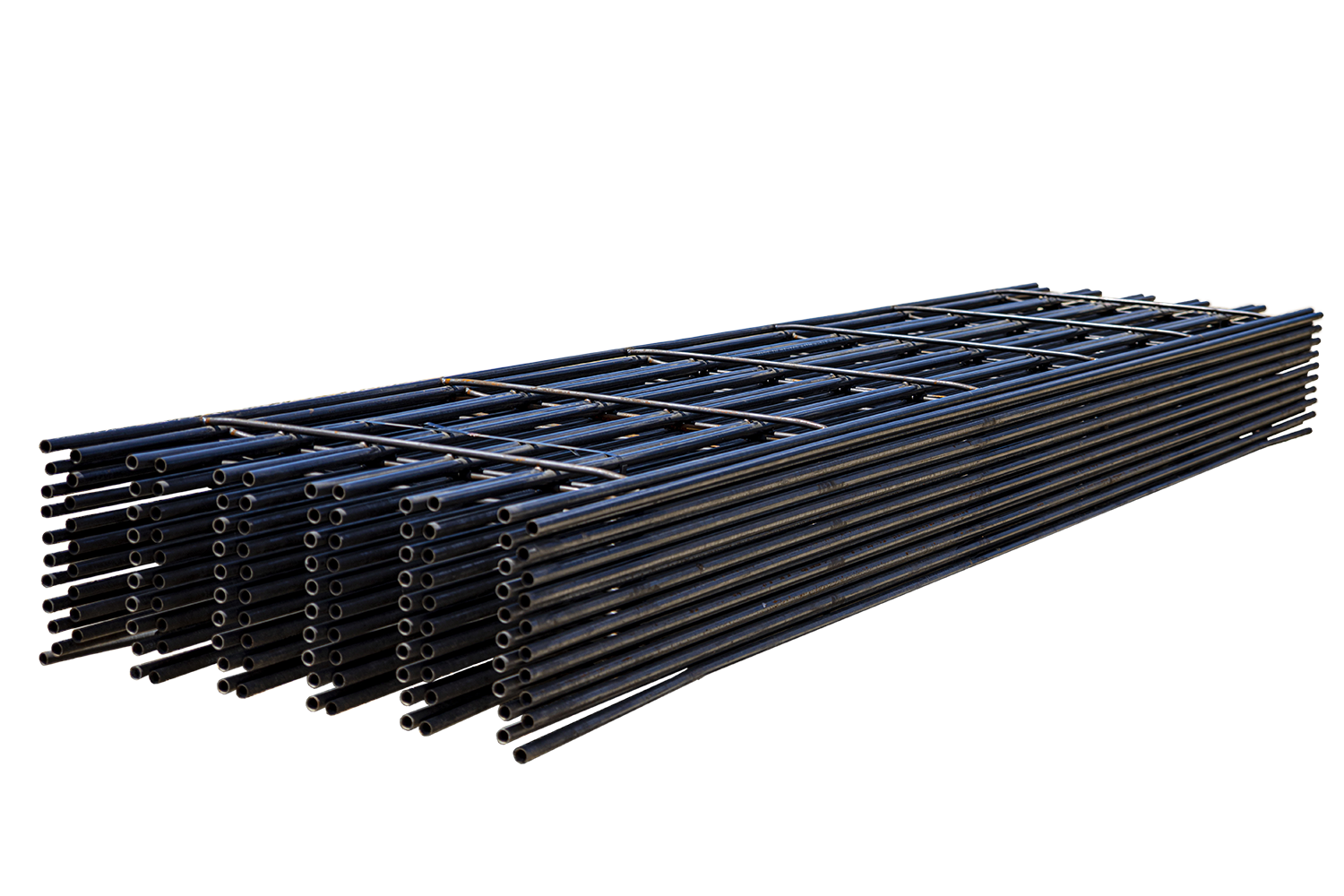

Black Steel Pipe: Black steel pipe is commonly used in gas distribution systems, plumbing, and infrastructure projects where a protective coating is not necessary. It is also utilized for low-pressure applications and as scaffolding or railing material.

In summary, the main differences between carbon steel pipe and black steel pipe lie in their composition, manufacturing process, surface finish, corrosion resistance, and applications. Carbon steel pipe contains additional elements and has better corrosion resistance, making it suitable for a wider range of applications. On the other hand, black steel pipe is more affordable and commonly used for non-corrosive applications. It’s important to consider these factors when selecting the appropriate pipe for your specific needs.

Is black steel pipe stronger than galvanized steel pipe ?

Yes, black steel pipe is generally considered to be stronger than galvanized steel pipe. The difference in strength between the two types of pipes is primarily due to the manufacturing process and the presence of a zinc coating on galvanized steel pipe.

Black steel pipe is made from plain carbon steel, which gives it a higher strength compared to galvanized steel pipe. The absence of a zinc coating allows black steel pipe to maintain its natural strength properties. This makes it suitable for applications where high strength is required, such as structural support, industrial piping systems, and heavy-duty infrastructure projects.

On the other hand, galvanized steel pipe is made by coating regular steel pipe with a layer of zinc. This coating acts as a protective barrier against corrosion, enhancing the durability of the pipe. However, the galvanizing process can slightly weaken the steel. The zinc coating adds some thickness to the pipe, which decreases the internal diameter and may affect its flow capacity. Additionally, galvanized steel pipe is more susceptible to cracking or chipping of the zinc coating, leading to potential corrosion in the exposed areas.

|

Material

|

A53 B, St37-2, St52-4,

|

|

Wall thickness

|

1mm~20mm

|

|

Outer Diameter

|

21.3MM~1620MM

|

|

Physical Property

|

API 5L, ASTM A53, ASTM A671-2006, ASTM A252-1998, ASTM A450-1996, ASME B36.10M, BS 1387

|

|

Grade

|

A53 B , ST37-ST52

|

|

Surface Treatment

|

1. Galvanized

2. Black 3. Transparent oil,anti-rust oil |

|

Pipe Ends

|

Plain end/Beveled,protected by plastic caps on both ends, cut quare,grooved,threaded and coupling,etc.

|

|

Certificate

|

API 5L,FM,UL, CE,

|

2 comments

bahis siteleri

2023年12月22日 at pm7:24

Is black steel pipe schedule 40?

Ronsun2023

2023年12月22日 at pm8:51

You can find Schedule 40 steel pipes in galvanized or black steel varieties in hardware stores.