3PE Coating Anti-Corrosion Insulation Steel Pipe

Enhancing Durability with 3PE Coating: Anti-Corrosion Insulation Steel Pipe

Introduction

In industries where steel pipes are extensively used, protection against corrosion is crucial to ensure durability and longevity. One effective method of achieving this is through the application of 3PE coating. In this article, we will explore the concept of 3PE coating, its benefits, and its role as an anti-corrosion insulation for steel pipes.

Technological processes

Upload pipes→pipes screw conveyor→rust removal of intermediate frequency heating→Epoxy powder coating→outer layer soli quid & polyethylene coating→cooling spray→pipes screw conveyor→grinding pipes, s end→unload pipes

Circumstance condition

3 kinds of working pipe:1).seamless steel pipe

2).spiral steel pipe

3).straight seam steel pipe

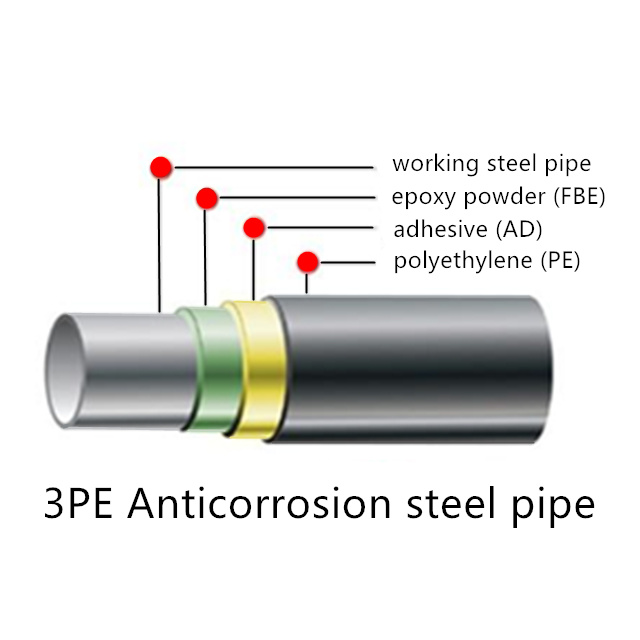

3 layers of outer wall surface:

*1st layer of epoxy powder (FBE> 100um)

*2nd layer of adhesive (AD)170~250um

*3rd layer polyethylene (PE) is 1.8~3.7mm

Other Anti-corrosion:

IPN8710

FBE Epoxy powder

Epoxy coal pitch

| Product name | Three PE anti-corrosive pipe |

| Length | 6m-12m ,or by customer’s requirements |

| Laid way | Buried |

| Application | Water,oil gas, Coal to gas |

| Production Standard | The national standard GB/T23257-2009 |

| Internal FBE Coating | |||||

| DN(mm) | FBE(μm) | ||||

| 100~500 | >350 | ||||

| 550~750 | >400 | ||||

| ≥800 | >450 | ||||

| External 3PE Coating | |||||

| DN(mm) | Expoxy powder coated(μm) | Adhesive(μm) | Min wall thickness of anticorrosive coating(mm) | ||

| 2 layer | 3 layer | Usual grade | Strengthen grade | ||

| ≤100 | ≥80 | 200~400 | 170~250 | 1.8 | 2.5 |

| 100 | ≥80 | 200~400 | 170~250 | 2 | 2.7 |

| 250 | ≥80 | 200~400 | 170~250 | 2.2 | 2.9 |

| 500 | ≥80 | 200~400 | 170~250 | 2.5 | 3.2 |

| ≥800 | ≥80 | 200~400 | 170~250 | 3 | 3.7 |

Indexes of anti-corrosive layer

| Item | Indexes | |

| Two layer | Three layer | |

| Peel strength(N/cm)

(20ºC±10ºC)/(50ºC±5ºC) |

≥70

≥35 |

≥100(cohesive failure)

≥70 (cohesive failure) |

| Cathodic disbonding

(65ºC,48h)/(mm) |

≤15 | ≤6 |

| Cathodic disbonding(the highest temperature,30d)/(mm) | ≤25 | ≤15 |

| Impact strength(J/mm) | ≥8 | |

| Counter bending(-20ºC,2.5°) | No crack | |

1. Understanding 3PE Coating

- What is 3PE Coating? 3PE coating, short for Three-Layer Polyethylene Coating, is a protective layer applied to steel pipes to prevent corrosion. It consists of three layers: an epoxy primer, an adhesive layer, and a polyethylene outer layer.

- How does it Work? The epoxy primer provides excellent adhesion to the steel surface, ensuring a strong bond. The adhesive layer acts as a protective barrier, preventing water or moisture from reaching the steel. The polyethylene outer layer provides resistance to chemicals, abrasion, and mechanical damage.

2. Advantages of 3PE Coating

- Superior Corrosion Resistance: The primary advantage of 3PE coating is its exceptional resistance to corrosion. The combination of the epoxy primer, adhesive layer, and polyethylene outer layer creates a strong barrier against corrosive elements, such as moisture, chemicals, and salts.

- Longevity and Durability: Steel pipes with 3PE coating have an extended lifespan due to their enhanced resistance to corrosion. This coating effectively protects the pipe from external factors, reducing maintenance and replacement costs.

- Chemical Resistance: The polyethylene outer layer of the 3PE coating provides resistance to various chemicals, making it suitable for a wide range of applications, including oil and gas pipelines, water supply systems, and chemical processing industries.

- Mechanical Protection: In addition to corrosion resistance, 3PE coating offers mechanical protection to steel pipes. The polyethylene layer acts as a shield against abrasion, impact, and external forces, ensuring the integrity of the pipe.

- Environmentally Friendly: 3PE coating is an environmentally friendly solution as it does not contain harmful substances. The coating is non-toxic, non-reactive, and does not release volatile organic compounds (VOCs) into the environment.

3. Application of 3PE Coating on Steel Pipes

- Preparation: Before applying the 3PE coating, the steel pipe undergoes surface preparation, including cleaning, degreasing, and roughening. This ensures proper adhesion of the coating to the pipe surface.

- Primer Application: The first layer of the 3PE coating is an epoxy primer. It is applied to the prepared surface of the steel pipe to provide adhesion and corrosion resistance.

- Adhesive Layer: Once the primer is applied, an adhesive layer is added. This layer acts as a bonding agent between the epoxy primer and the polyethylene outer layer.

- Polyethylene Outer Layer: The final layer of the 3PE coating is the polyethylene outer layer. It provides mechanical protection and resistance to chemicals, abrasion, and impact.

4. Benefits of Anti-Corrosion Insulation Steel Pipes with 3PE Coating

- Extended Service Life: Steel pipes with 3PE coating have a significantly longer service life compared to uncoated pipes. The corrosion-resistant properties of the coating help prevent deterioration and maintain the structural integrity of the pipes.

- Reduced Maintenance Costs: By protecting the steel pipes from corrosion, 3PE coating reduces the need for frequent maintenance and repairs, resulting in cost savings for industries relying on steel pipelines.

- Enhanced Reliability: Steel pipes with 3PE coating provide a reliable and consistent performance, even in harsh environments. The coating ensures the pipes can withstand corrosive elements, maintaining a consistent flow of fluids or gases.

- Versatile Applications: 3PE coating is suitable for various industries, including oil and gas, water supply, chemical processing, and infrastructure development. Its versatility makes it an ideal choice for both underground and aboveground applications.

Conclusion

The application of 3PE coating on steel pipes offers numerous advantages, primarily by providing exceptional corrosion resistance and insulation. The coating’s three-layer structure, consisting of an epoxy primer, adhesive layer, and polyethylene outer layer, effectively protects the steel pipes from corrosion, chemicals, abrasion, and impact. This results in extended service life, reduced maintenance costs, and enhanced reliability of steel pipelines in various industries. With its environmentally friendly nature and versatile applications, 3PE coating stands as a reliable solution for anti-corrosion insulation of steel pipes, ensuring durability and longevity in demanding environments.

2 comments

tells

2023年12月22日 at pm5:23

What is 3PE coating?

Ronsun2023

2023年12月22日 at pm8:59

3PE, which stands for “Three-Layer Polyethylene,” is a common coating used to protect steel pipes from corrosion and extend their service life, especially in applications where the pipes are exposed to harsh environments, such as in the oil and gas industry