FBE Coating Pipe | Fusion Bonded Epoxy Coating

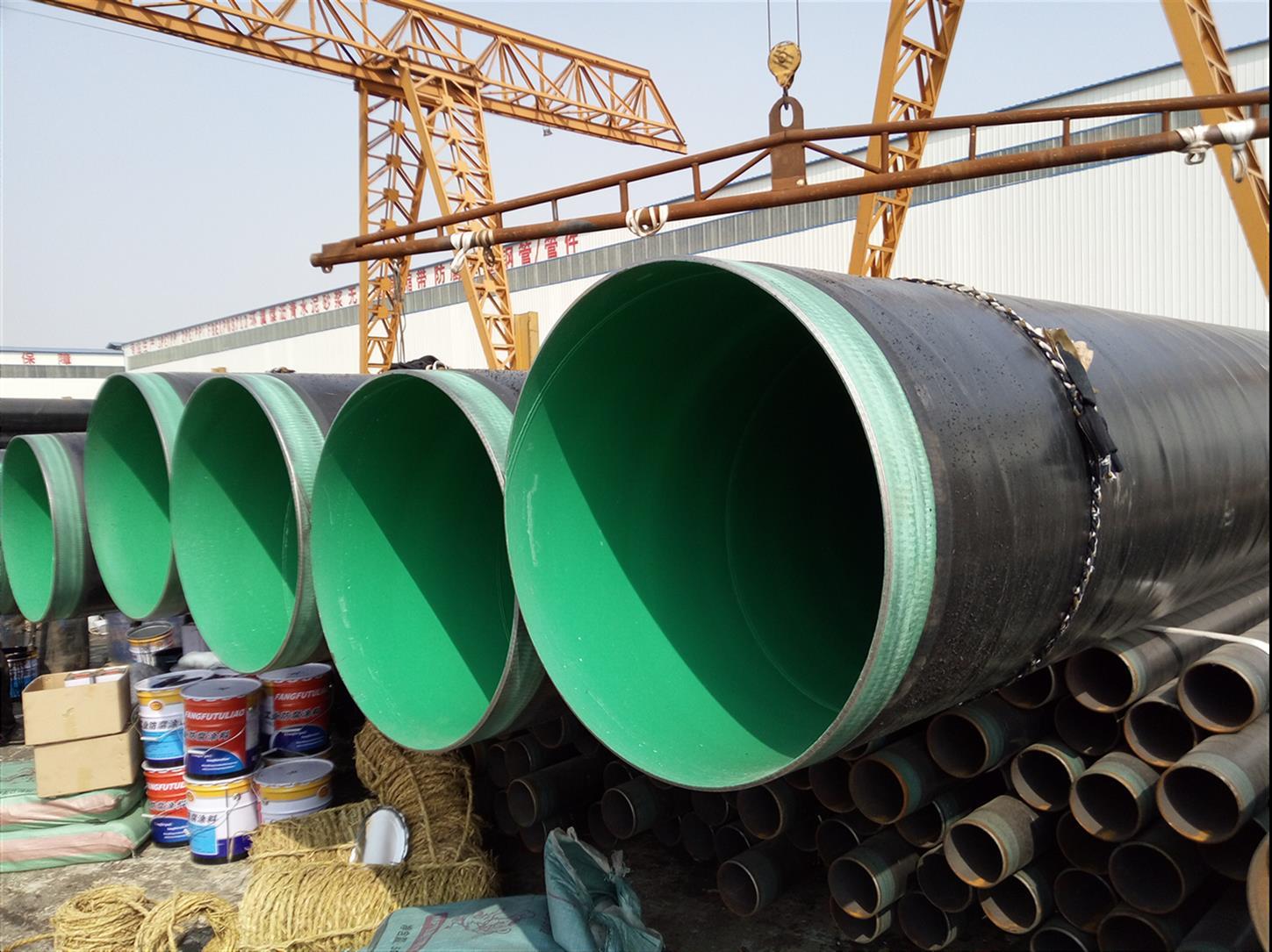

FBE (Fusion Bonded Epoxy) Coating Pipe

Fusion Bonded Epoxy (FBE) is a type of anti-corrosive coating that’s applied to the surface of steel pipes to protect them from corrosion. It’s widely used in the oil and gas industry, among others, to prevent rust and corrosion in pipelines.

![]() FBE Coating Pipe Introduction

FBE Coating Pipe Introduction

| Product: | FBE (Fusion Bond Epoxy) Coated Pipe, Epoxy Coated Carbon Steel Pipe |

| Application: | Used for Coal mine,heat and power plant,oil and gas transmission |

| Standard: | DIN30670,CAN/CSA-Z245.21 |

| Size: | OD:219-2000MM |

| Pakcing: | in bundles, in loose, Nylon Strip for each bundle for piece pipe |

| Color | RAL colors coating powder |

| Service: | anti-chemical corrosion and water resistance strong |

![]() Thickness Of FBE Coating Pipe

Thickness Of FBE Coating Pipe

minimum 125 µm epoxy layer thickness

minimum 150 µmco-polymer layer thickness

minimum thickness of 1.8 mm to 4.7 mm polyethylene or polypropylene layer

minimum total layer thickness range

| M kg/m | Layer thickness in mm | ||||||||

| Class A1 | Class A2 | Class A3 | Class B1 | Class B2 | Class B3 | Class C1 | Class C2 | Class C3 | |

| M ≤ 15 | 1,8 | 2,1 | 2,6 | 1,3 | 1,8 | 2,3 | 1,3 | 1,7 | 2,1 |

| 15 < M ≤ 50 | 2,0 | 2,4 | 3,0 | 1,5 | 2,1 | 2,7 | 1,5 | 1,9 | 2,4 |

| 50 < M ≤ 130 | 2,4 | 2,8 | 3,5 | 1,8 | 2,5 | 3,1 | 1,8 | 2,3 | 2,8 |

| 130 < M ≤ 300 | 2,6 | 3,2 | 3,9 | 2,2 | 2,8 | 3,5 | 2,2 | 2,5 | 3,2 |

| 300 < M | 3,2 | 3,8 | 4,7 | 2,5 | 3,3 | 4,2 | 2,5 | 3,0 | 3,8 |

| Please note: The total required thickness may be reduced for SAW pipes by a maximum of 10% on joint seam. Class 1 and 2 for medium and light applications (sandy soil). Class 3 – application in extreme conditions (rocky soil) or underwater. |

|||||||||

Structure of FBE Coated Pipe

An FBE coated pipe typically has two layers:

- Steel Pipe: The primary material that transports substances such as oil, gas, or water.

- FBE Coating: A layer of epoxy powder is applied to the pipe to protect the steel from corrosion. The thickness of the FBE layer can vary depending on the requirements but is generally between 250 and 500 microns.

Process of FBE Coating

The process of applying FBE coating to a pipe involves several steps:

- Surface Preparation: The pipe surface is prepared through a process called abrasive blasting to remove any oil, grease, mill scale, rust, or other contaminants. This creates a rough surface profile that allows the FBE coating to strongly adhere to the pipe.

- Heating: The pipe is then heated to a high temperature, typically around 230-250°C (446-482°F), in preparation for the FBE application.

- Powder Application: The epoxy powder is applied to the hot pipe using an electrostatic spray gun. The heat causes the powder to melt and form a uniform layer on the pipe surface.

- Curing: The coated pipe is allowed to cool, during which time the epoxy cures and forms a solid, hard, and chemically resistant layer.

Advantages of FBE Coating

FBE coating offers several benefits:

- Corrosion Protection: It provides excellent protection against corrosion, extending the life of the pipe.

- Chemical Resistance: FBE coating is resistant to various chemicals, making it suitable for transporting different types of substances.

- Smooth Surface: The FBE coating provides a smooth surface on the pipe, which can improve flow efficiency.

- Adherence: FBE coating has strong adhesion to steel, providing a long-lasting protective layer.

Standards for FBE Coating

The application of FBE coating on pipes is guided by international standards such as:

- NACE RP0394: This standard provides guidelines for the use of protective coatings for corrosion control of underground systems.

- ISO 21809-2: This standard specifies the requirements for the qualification, application, testing, and handling of materials for plant-applied single layer fusion-bonded epoxy (FBE) external coatings for the corrosion protection of bare steel pipe for use in pipeline transportation systems.

APPLICATIONS

![]() Minimum thickness of finished coating

Minimum thickness of finished coating

| Pipe Sizes (Specified OD) | Minimum Coating Thickness Chart (mm) |

| ≤ 10 3 /4” (273.1 mm) | 2.5 |

| > 12 3 /4” ( 323.9 mm) to ≤ 18” (457 mm) | 2.8 |

| > 20″ (508.0 mm) to ≤ 30″ (762 mm) | 3.0 |

| > 32″ (813.0 mm) | 3.3 |

![]() Thickness of FBE coating on steel pipes

Thickness of FBE coating on steel pipes

| DN (mm) | Epoxy Powder (μm) | Adhesive Layer (μm) | Min. Thickness on The Coating (mm) | |

| Common Level (G) | Strengthen Level (S) | |||

| DN ≤ 100 | ≥120 | ≥170 | 1.8 | 2.5 |

| 100 < DN ≤250 | 2.0 | 2.7 | ||

| 250 < DN < 500 | 2.2 | 2.9 | ||

| 500 ≤DN < 800 | 2.5 | 3.2 | ||

| DN ≥ 800 | 3.0 | 3.7 | ||

How does the cost of FBE coating compare to other types of coatings?

The cost of Fusion Bonded Epoxy (FBE) coating can vary depending on a number of factors such as the thickness of the coating, the size of the pipe, and the specific application requirements. However, generally speaking, FBE coating is considered to be a cost-effective solution for corrosion protection, particularly in comparison to some other types of coatings.

Here are some general comparisons:

FBE vs. 3LPE (Three-Layer Polyethylene) or 3LPP (Three-Layer Polypropylene): FBE is generally less expensive than 3LPE or 3LPP coatings. This is because the process of applying a three-layer coating is more complex and time-consuming than the single-layer FBE coating process. However, 3LPE and 3LPP coatings may offer superior performance in certain applications, such as higher temperature environments or more aggressive soil conditions.

FBE vs. Galvanizing: FBE coating is typically more expensive than galvanizing. However, FBE often offers superior corrosion protection, particularly in harsh environments. Additionally, FBE can be applied in a wider range of thicknesses, allowing for greater control over the level of protection provided.

FBE vs. Internal Coatings (like Liquid Epoxy): For internal pipe coatings, liquid epoxy can often be less expensive than FBE. However, the choice between FBE and liquid epoxy will also depend on the specific application requirements.

It’s important to note that while the initial cost is a key consideration, the total lifecycle cost should also be considered. This includes the cost of potential maintenance, repairs, or replacement if the coating fails to provide adequate protection. In many cases, spending more upfront on a high-quality coating like FBE can result in significant cost savings over the long term.