Butt Weld Neck Flanges – Stainless Steel Pipe Forged

Stainless Steel Pipe Fittings: A Guide to Forged Butt Weld Neck Flanges

Introduction

In the world of industrial piping systems, stainless steel pipe fittings are widely used for their durability, corrosion resistance, and versatility. One such fitting is the forged butt weld neck flange, which plays a crucial role in connecting pipes and providing a leak-proof seal. This comprehensive guide will provide you with all the essential information about stainless steel forged butt weld neck flanges, including their features, specifications, and applications. Whether you are a professional in the industry or simply curious about pipe fittings, this article will equip you with the knowledge you need.

Understanding Forged Butt Weld Neck Flanges

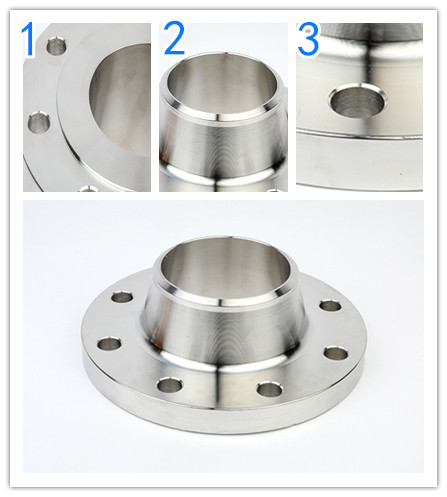

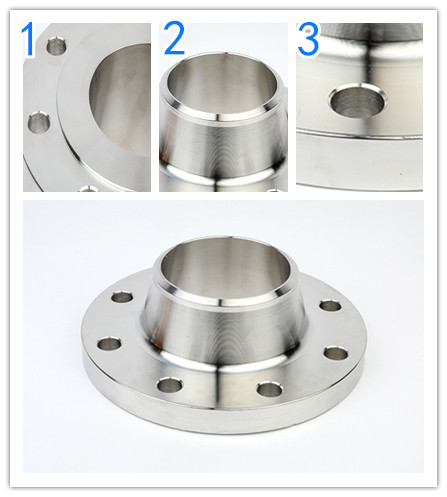

A forged butt weld neck flange is a type of flange that is welded to the end of a pipe or fitting. It has a long tapered hub and a smooth, continuous bore, which allows for a smooth flow of fluids or gases. The neck of the flange provides additional reinforcement and strength, making it suitable for high-pressure and high-temperature applications. The butt weld connection ensures a secure and leak-proof joint between the flange and the pipe.

Key Features and Specifications

- Type: Forged butt weld neck flange

- Material: Stainless steel (various grades available)

- Size: 1/2″ to 60″

- Pressure rating: Class 150 to Class 2500

- Standards: ASME B16.5, ASME B16.47, MSS SP-44, API, and others

- Face: Raised face (RF), flat face (FF), ring type joint (RTJ)

- Manufacturing process: Forging

Material and Grades

Stainless steel forged butt weld neck flanges are available in various grades, each offering different levels of corrosion resistance and mechanical properties. Some commonly used stainless steel grades for flanges include:

- 304/304L: This grade is the most commonly used stainless steel for flanges. It offers excellent corrosion resistance and is suitable for a wide range of applications.

- 316/316L: This grade has superior corrosion resistance compared to 304/304L. It is often used in environments with high chloride content or corrosive chemicals.

- 321/321H: This grade contains titanium, which stabilizes the stainless steel against carbide precipitation during welding. It is suitable for high-temperature applications.

- 347/347H: This grade contains niobium, which improves its resistance to intergranular corrosion. It is commonly used in applications involving high temperatures and sensitization to carbide precipitation.

Pressure Ratings and Standards

Forged butt weld neck flanges are available in different pressure ratings, ranging from Class 150 to Class 2500. The pressure rating indicates the maximum pressure that the flange can withstand without failure. It is important to select the appropriate pressure rating based on the specific requirements of the application.

These flanges are manufactured according to industry standards such as ASME B16.5, ASME B16.47, MSS SP-44, and API. These standards define the dimensions, materials, and testing requirements for flanges, ensuring compatibility and reliability.

Item Sizes and Pressure Classes for Flanges

Flanges are crucial components in piping systems that facilitate the connection of pipes, valves, and other equipment. They play a vital role in ensuring easy assembly and disassembly, as well as providing sealing and support. Flanges come in various sizes and pressure classes to cater to different applications and requirements.

Understanding Flange Sizes

Flange sizes are typically measured in inches and are based on the nominal pipe size (NPS) they are designed to fit. The NPS is a standardized system that indicates the approximate inside diameter of the pipe. Flanges are available in a wide range of sizes, from small diameters to large ones, to accommodate different pipe dimensions.

Here are some common flange sizes:

- 1/2 inch (NPS 0.5)

- 1 inch (NPS 1)

- 2 inches (NPS 2)

- 4 inches (NPS 4)

- 8 inches (NPS 8)

- 12 inches (NPS 12)

- 24 inches (NPS 24)

Selecting the correct flange size that matches the pipe size is crucial to ensure a proper fit and connection.

Pressure Classes for Flanges

Flanges are also classified based on their pressure ratings or pressure classes. The pressure class indicates the maximum pressure that a flange can withstand without failure. It is essential to choose the appropriate pressure class for a specific application to ensure the safety and integrity of the piping system.

The most common pressure classes for flanges are:

- 150 LB (Pound)

- 300 LB (Pound)

- 400 LB (Pound)

- 600 LB (Pound)

- 900 LB (Pound)

- 1500 LB (Pound)

- 2500 LB (Pound)

Applications of Forged Butt Weld Neck Flanges

Forged butt weld neck flanges find their applications in various industries due to their strength, durability, and leak-proof design. Some common applications include:

- Oil and Gas Industry: Forged butt weld neck flanges are extensively used in oil and gas pipelines, refineries, and offshore platforms. They provide a secure connection and withstand high-pressure and high-temperature conditions.

- Chemical and Petrochemical Industry: These flanges are suitable for chemical processing plants, where they are used to connect pipes and equipment that handle corrosive chemicals. The stainless steel material offers excellent resistance to corrosion.

- Power Generation: Power plants, including thermal, nuclear, and renewable energy facilities, utilize forged butt weld neck flanges for connecting pipes and equipment. They ensure the integrity of the piping system, even under high-pressure conditions.

- Water and Wastewater Treatment: These flanges are used in water treatment plants, where they connect pipes and equipment for the purification and distribution of water. The leak-proof design ensures the efficient operation of the treatment system.

- Food and Beverage Industry: Stainless steel forged butt weld neck flanges are commonly used in the food and beverage industry, where hygiene and corrosion resistance are crucial. They connect pipes and equipment for processing and transporting food and beverages.

Frequently Asked Questions (FAQ)

1. What is the difference between raised face (RF) and ring type joint (RTJ) faces in forged butt weld neck flanges?

The raised face (RF) is a common face type for forged butt weld neck flanges. It features a raised surface that creates a better seal when compressed against a gasket. The ring type joint (RTJ) faceis a specialized face type used in high-pressure and high-temperature applications. It consists of a groove and a metal ring that sits inside the groove. When the flange is bolted, the metal ring is compressed, creating a tight seal.

2. How do I select the right size of forged butt weld neck flange for my application?

The size of the flange depends on the size of the pipe it needs to connect to. It is important to consider the outer diameter (OD) and wall thickness of the pipe when selecting the flange size. Consulting industry standards and guidelines can help determine the appropriate flange size for your specific application.

3. Can forged butt weld neck flanges be used for both carbon steel and stainless steel pipes?

Yes, forged butt weld neck flanges can be used with both carbon steel and stainless steel pipes. However, it is essential to ensure compatibility between the flange material and the pipe material to prevent galvanic corrosion. Using a flange made of the same material as the pipe is generally recommended.

4. How are forged butt weld neck flanges installed?

To install a forged butt weld neck flange, the pipe end is first beveled to create a V-shaped groove. The flange is then aligned with the pipe and welded around the circumference of the joint. The weld ensures a strong and leak-proof connection. It is important to follow proper welding procedures and techniques to ensure a secure joint.

5. Can forged butt weld neck flanges be used in high-temperature applications?

Yes, forged butt weld neck flanges are suitable for high-temperature applications. The stainless steel material used in these flanges offers excellent resistance to high temperatures and thermal stress. However, it is important to select the appropriate stainless steel grade based on the specific temperature requirements of the application.