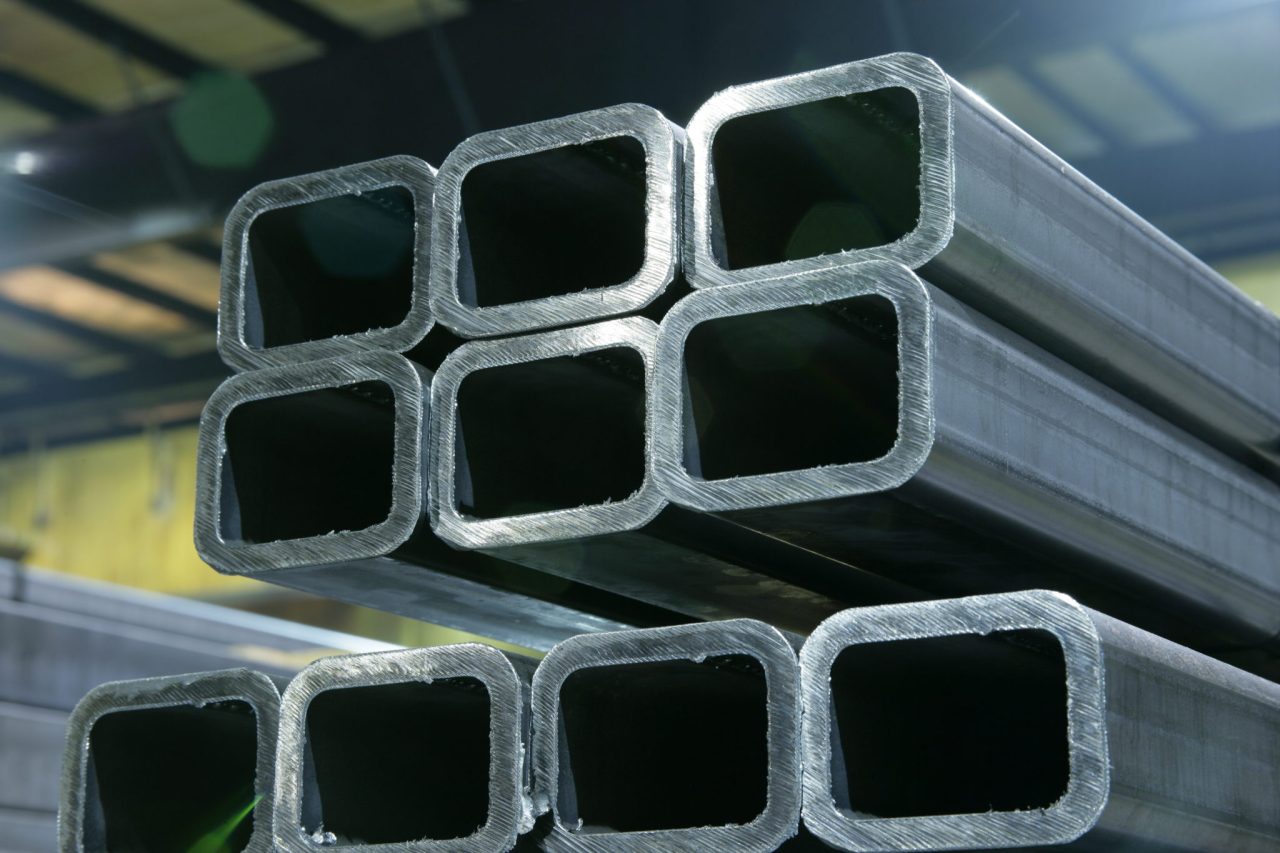

Exploring Stainless Steel Hollow Sections

Exploring Stainless Steel Hollow Sections: EN 10296-2, A312, A358, A778, A790, A928

Introduction:

Stainless steel hollow sections are widely used in various industries due to their exceptional corrosion resistance, durability, and aesthetic appeal. Different standards govern the manufacturing and specifications of stainless steel hollow sections, including EN 10296-2, A312, A358, A778, A790, and A928. In this article, we will delve into these standards, providing insights into their characteristics and applications.

- EN 10296-2:

EN 10296-2 is a European standard that specifies the technical delivery conditions for stainless steel tubes and hollow sections for general purposes. This standard covers a wide range of sizes, grades, and thicknesses of stainless steel hollow sections, making it applicable to diverse industrial sectors such as construction, transportation, and manufacturing. - ASTM A312:

ASTM A312 is an American standard that covers seamless, welded, and heavily cold worked austenitic stainless steel pipes. Although primarily focused on pipes, ASTM A312 can also apply to stainless steel hollow sections. The standard provides guidelines for material composition, mechanical properties, manufacturing processes, and dimensions, ensuring high-quality products for applications in industries such as oil and gas, chemical processing, and power generation. - ASTM A358:

ASTM A358 is another American standard specifically designed for electric-fusion-welded austenitic stainless steel pipes. While the standard refers to pipes, stainless steel hollow sections fabricated using the electric-fusion welding process can also adhere to ASTM A358. This standard includes requirements for chemical composition, mechanical properties, manufacturing methods, and dimensions, and it finds applications in industries such as petrochemical, pharmaceutical, and food processing. - ASTM A778:

ASTM A778 is an American standard that covers welded, unannealed austenitic stainless steel tubular products, including hollow sections. The standard is applicable to various grades of stainless steel and specifies the requirements for dimensions, tolerances, mechanical properties, and surface finishes. ASTM A778 stainless steel hollow sections are commonly utilized in architectural and structural applications, as well as in the automotive and transportation industries. - ASTM A790:

ASTM A790 is an American standard that covers seamless and welded ferritic/austenitic stainless steel pipes, also known as duplex and super duplex stainless steel. Although primarily focused on pipes, ASTM A790 can be relevant to stainless steel hollow sections made from duplex or super duplex grades. The standard provides requirements for chemical composition, mechanical properties, manufacturing processes, and dimensions, making it suitable for applications in offshore oil and gas, chemical processing, and desalination plants. - ASTM A928:

ASTM A928 is an American standard specifically developed for ferritic/austenitic (duplex) stainless steel electric-fusion-welded pipe. Similar to other standards, ASTM A928 can also apply to stainless steel hollow sections produced using the electric-fusion welding process. The standard outlines the requirements for chemical composition, mechanical properties, manufacturing methods, dimensions, and testing. ASTM A928 stainless steel hollow sections find applications in industries such as pulp and paper, marine, and wastewater treatment.

Conclusion:

Stainless steel hollow sections, governed by standards such as EN 10296-2, A312, A358, A778, A790, and A928, offer a wide range of options for various industries. These standards ensure the quality, performance, and dimensional accuracy of stainless steel hollow sections, making them suitable for applications in construction, transportation, manufacturing, architecture, and more. Whether you are seeking corrosion resistance, durability, or aesthetic appeal, stainless steel hollow sections produced in accordance with these standards can meet your requirements and provide long-lasting solutions.

Stainless steel hollow sections are an essential component in various structural applications due to their exceptional strength, durability, and corrosion resistance. These hollow sections, also known as stainless steel tubes or profiles, are formed through different manufacturing processes to create a wide range of shapes and sizes. In this article, we will explore the characteristics, advantages, and applications of stainless steel hollow sections, highlighting their importance in modern construction and engineering.

Introduction:

Characteristics of Stainless Steel Hollow Sections:

- Corrosion Resistance:

One of the most remarkable properties of stainless steel hollow sections is their excellent corrosion resistance. Stainless steel contains a minimum of 10.5% chromium, which forms a protective oxide layer on the surface, preventing the material from rusting or corroding. This makes stainless steel hollow sections ideal for applications in corrosive environments, such as marine structures, chemical plants, and wastewater treatment facilities. - Strength and Durability:

Stainless steel hollow sections exhibit high strength and durability, making them suitable for supporting heavy loads and withstanding extreme conditions. The material’s mechanical properties, such as tensile strength and yield strength, ensure structural integrity and long-term performance. Stainless steel hollow sections can withstand impacts, vibrations, and thermal stresses, making them ideal for applications in construction, transportation, and infrastructure. - Aesthetic Appeal:

In addition to their functional properties, stainless steel hollow sections offer an appealing aesthetic appearance. The smooth and shiny surface of stainless steel enhances the visual appeal of structures, making them a popular choice in architectural and design-oriented projects. Stainless steel hollow sections can be used as structural elements or design features to create visually striking and modern structures.

Advantages of Stainless Steel Hollow Sections:

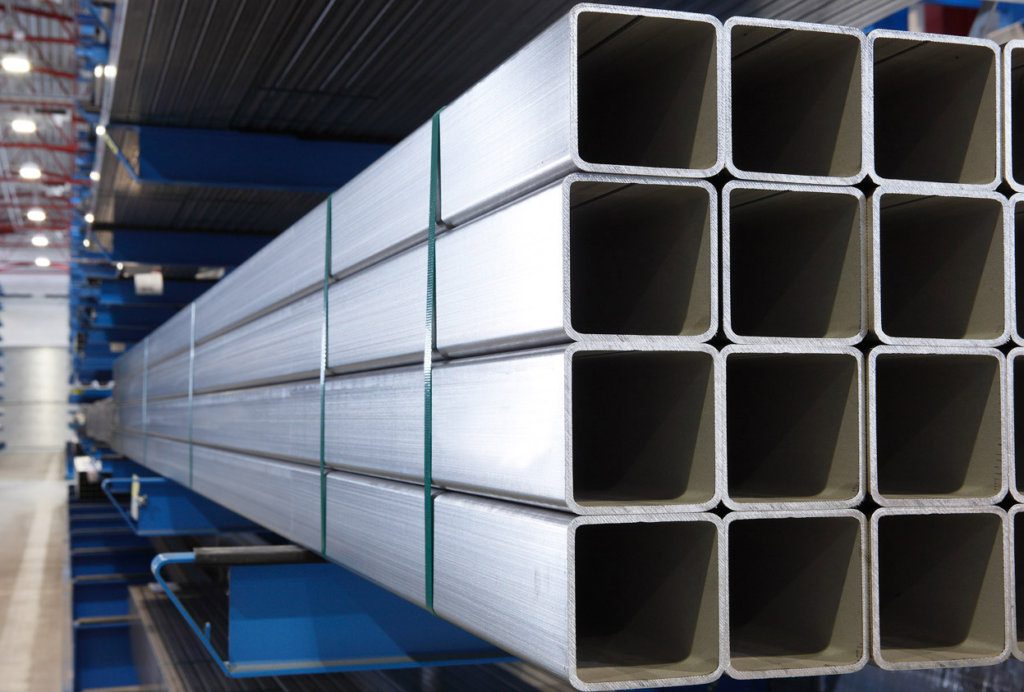

- Versatility:

Stainless steel hollow sections come in a wide range of shapes, including square, rectangular, circular, and elliptical, offering versatility in design and construction. This allows architects, engineers, and designers to create unique and customized structures according to their specific requirements. The flexibility in shape and size makes stainless steel hollow sections an adaptable solution for different applications. - Cost-Effective:

Although stainless steel hollow sections may have a higher initial cost compared to other materials, their long-term benefits make them a cost-effective choice. The material’s longevity, low maintenance requirements, and resistance to corrosion reduce the need for frequent repairs and replacements. Stainless steel hollow sections have a long service life, resulting in significant cost savings over time.

Applications of Stainless Steel Hollow Sections:

- Structural Construction:

Stainless steel hollow sections play a vital role in structural construction, providing support and stability to buildings, bridges, stadiums, and other infrastructure projects. They are commonly used in columns, beams, trusses, and framework. The material’s strength, durability, and corrosion resistance make it suitable for both indoor and outdoor applications, ensuring the longevity and safety of structures. - Architectural Design:

Stainless steel hollow sections are widely used in architectural design to create visually appealing structures. They can be employed as decorative elements, facades, handrails, and balustrades, adding a sleek and modern touch to buildings, public spaces, and residential areas. The material’s aesthetic appeal, along with its durability and corrosion resistance, makes stainless steel hollow sections a preferred choice for architects and designers. - Industrial Applications:

Stainless steel hollow sections find extensive use in various industrial applications. They are utilized in the manufacturing of machinery, equipment, and storage systems. In the chemical, pharmaceutical, and food processing industries, stainless steel hollow sections are vital for constructing tanks, vessels, and pipelines, ensuring the safe storage and transportation of liquids and gases. - Transportation:

The transportation industry also benefits from stainless steel hollow sections. They are used in the construction of railway bridges, highway guardrails, shipbuilding, and aerospace applications. Stainless steel’s strength, light weight, and corrosion resistance are crucial factors in ensuring the safety, efficiency, and longevity of transportation infrastructure.