How to purchase suitable pipe flange?

How to Select the Appropriate Flange for Procurement – Understanding Flanges in Piping Systems

A flange is a mechanical device used to join pipes, valves, or other equipment. It’s essentially a flat or raised ring with bolt holes for attachment. Flanges are usually made from materials such as steel or stainless steel that provide high strength and corrosion resistance.

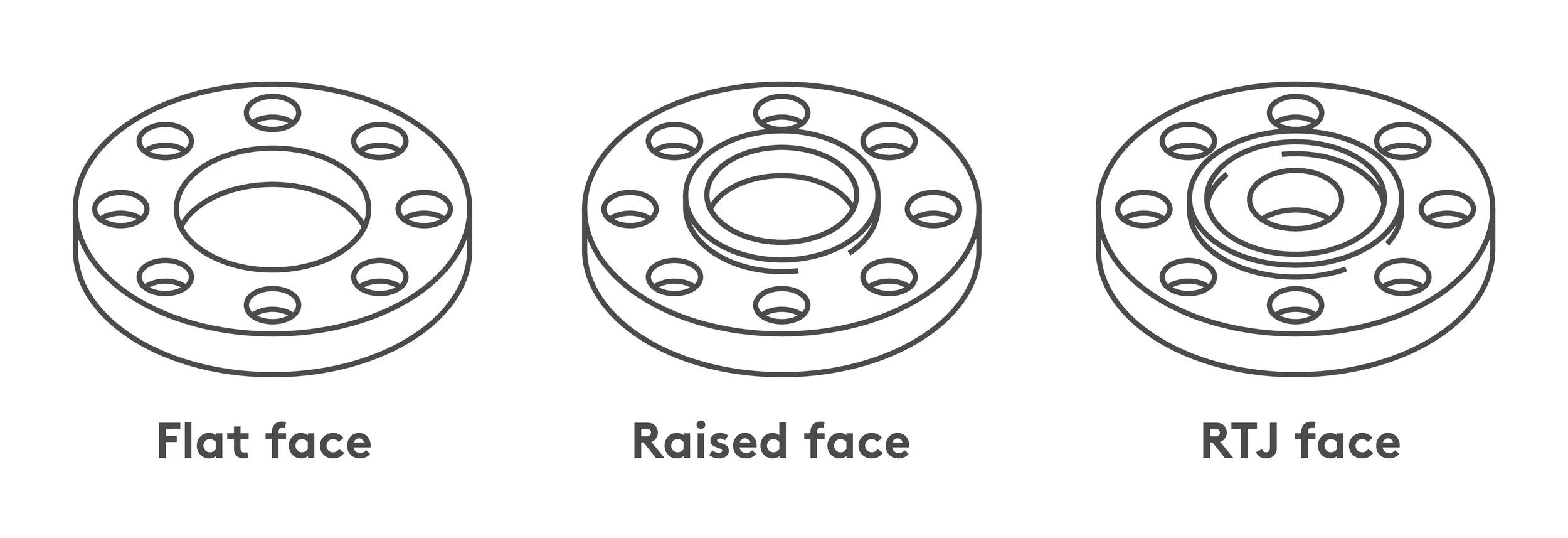

Flange Dimensions

The nominal size of a flange should correspond to the bore size of the connecting pipe. The flange rating, ranging from 150# to 2500#, indicates its pressure and temperature performance. Welding neck flanges require a schedule that corresponds to the pipe schedule.

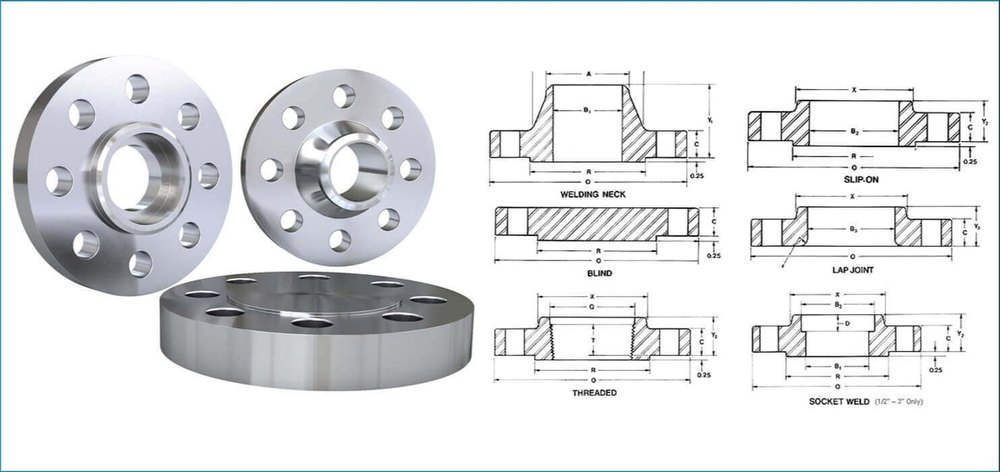

Types of Flanges

Flanges come in various types, including welding neck, blind, socket weld, lap joint, threaded flanges, and others. There are also special types like swivel flanges, expander/reducer flanges, Nipoflange/Weldoflange, and orifice flanges.

Welding neck, slip-on, and socket weld flanges are ideal for high-pressure applications. Threaded flanges are suitable for low-pressure systems as long as no vibrations are present. Lap joint flanges are often used with stub ends to reduce the cost of using high-grade materials.

Flange Material Considerations

Flanges need to withstand high temperatures, pressure, vibrations, and corrosion. Therefore, the choice of flange material is vital. Common materials include steel for high-stress applications, stainless steel for durability and corrosion resistance, aluminum for lightweight applications, and ductile iron as a cost-effective alternative to steel.

The manufacturing process also matters. Plate flanges are cheap but may lack the strength of other methods. Cast flanges offer flexibility at a lower cost, while forged flanges, though expensive, result in the strongest flanges.

Application Specific Selection

The choice of flange material depends on factors like pressure, temperature, medium, and service conditions. It’s crucial to evaluate the properties and limitations of each material to meet the requirements of your piping system.

Consultation of Flange Standards

Flange standards specify the chemical composition, dimensions, and other specifications for flanges. ASTM, Guobiao (GB), American Water Works Association (AWWA), ANSI, and ASME provide various standards applicable to different flange materials.

Flange Material Source

The choice of flange material source is also crucial. In some cases, domestically produced materials may be necessary due to the ‘Buy America’ standard or the American Iron & Steel (AIS) standard.

Other Factors

In addition to material, other factors to consider when choosing flanges include pipe material, pressure and temperature ratings, flange dimensions, and tolerances. The fitting type is also essential, especially when welding is required.

By referring to the standards required for the intended application, considering the pipe material, and ensuring that the chosen flange material can withstand the necessary temperature and pressure, you can select the ideal flange material. For further information or assistance, please contact Newzel Industries.