Polyurethane Foam Pre-Insulated Steel Pipe

Polyurethane Foam Pre-Insulated Steel Pipe: Enhancing Efficiency and Energy Conservation

Introduction

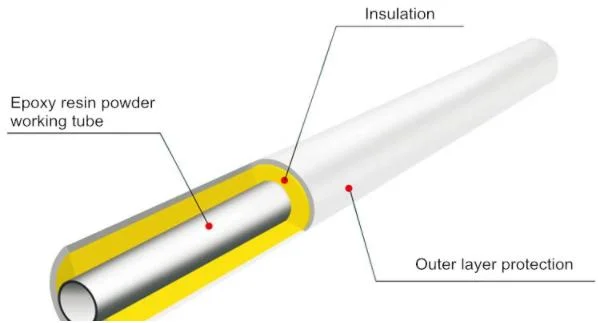

Polyurethane foam pre-insulated steel pipe is a highly efficient and effective solution for thermal insulation in various industries. It consists of an inner steel pipe, a layer of polyurethane foam insulation, and an outer protective casing. This article aims to explore the concept of polyurethane foam pre-insulated steel pipe, its advantages, and its role in enhancing efficiency and energy conservation.

1. Understanding Polyurethane Foam Pre-Insulated Steel Pipe

- What is Polyurethane Foam Pre-Insulated Steel Pipe? Polyurethane foam pre-insulated steel pipe is a composite pipe system designed for the transportation of fluids at different temperatures. It provides excellent thermal insulation properties, minimizing heat transfer and maintaining the desired temperature throughout the system.

- How does it Work? The polyurethane foam insulation layer acts as a barrier, reducing heat loss or gain from the fluid being transported. The steel pipe provides mechanical strength and durability to the system, while the outer casing protects the insulation and steel pipe from external elements.

2. Advantages of Polyurethane Foam Pre-Insulated Steel Pipe

- Superior Insulation Performance: Polyurethane foam pre-insulated steel pipe offers exceptional thermal insulation properties, significantly reducing heat transfer and energy losses. This results in improved energy efficiency, lower operating costs, and reduced environmental impact.

- Condensation Prevention: The insulation layer of polyurethane foam prevents condensation from forming on the outer surface of the pipe. This eliminates the risk of corrosion and damage to the system, ensuring its longevity and reliability.

- Mechanical Strength and Durability: The steel pipe component of the system provides excellent mechanical strength and durability, making it suitable for underground or aboveground installations. It can withstand external loads, soil movement, and other stresses without compromising the integrity of the insulation.

- Ease of Installation: Polyurethane foam pre-insulated steel pipes are designed for easy installation. The pipes are pre-fabricated and can be easily joined using various connection methods, minimizing installation time and labor costs.

- Versatile Applications: Polyurethane foam pre-insulated steel pipes find applications in various industries, such as district heating and cooling, hot water supply, oil and gas transportation, and industrial processes. Their versatility makes them suitable for both aboveground and underground installations.

3. Manufacturing Process of Polyurethane Foam Pre-Insulated Steel Pipe

- Steel Pipe Production: The inner steel pipe is manufactured using high-quality carbon steel or stainless steel, depending on the application requirements. The pipe is produced in various sizes and lengths to accommodate different project needs.

- Insulation Application: The polyurethane foam insulation is applied to the outer surface of the steel pipe. This is done using a specialized insulation machine that sprays the liquid polyurethane foam onto the pipe, allowing it to expand and adhere to the surface. The foam is then cured to form a rigid and closed-cell insulation layer.

- Outer Casing Installation: After the insulation has cured, an outer casing is installed to protect the insulation and steel pipe. The casing can be made from materials such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC). It provides additional mechanical protection and prevents moisture ingress.

4. Benefits of Polyurethane Foam Pre-Insulated Steel Pipe

- Energy Conservation: The superior insulation properties of polyurethane foam pre-insulated steel pipes significantly reduce heat transfer and energy losses, resulting in energy conservation and cost savings.

- Environmental Sustainability: By minimizing energy consumption and reducing greenhouse gas emissions, polyurethane foam pre-insulated steel pipes contribute to a more sustainable and environmentally friendly infrastructure.

- Long-Term Performance: The combination of polyurethane foam insulation and steel pipe ensures long-term performance with minimal maintenance requirements. The system remains efficient and reliable throughout its lifespan.

- Cost-Effective Solution: Although the initial cost of polyurethane foam pre-insulated steel pipes may be higher than traditional piping systems, the long-term energy savings and reduced maintenance costs make them a cost-effective solution in the long run.

- Enhanced System Efficiency: The excellent thermal insulation properties of the pipes result in reduced heat loss or gain, ensuring optimal temperature conditions and system efficiency.

A pre-insulated pipe normally consists of three parts

Part 1: Carrier pipe (Inside): Stainless steel or Carbon steel

Part 2: Insulating layer (Medium): Polyurethane foam (PUR Form) (High insulation qualities compared to mass and volume)

Part 3: Protective jacket (Outside casing): Plastic or steel (Polyethylene (PEH), High Density Polyethylene (HDPE), Galvanized, Aluminum etc)

Pos: The choice of carrier pipe, foam type and foam thickness, as well as the material for the jacket, is made by the customer, who can also choose to supply carrier pipes for the project.

Advantages: impact-proof, watertight, resistant to salt and chemicals, hygienic and non-corrosive

| Materials | ||

| Item | Material | Notes |

| Service pipe/Carrier pipe | Steel Pipe | API 5L PSL-1: GR.B X42, X46, X52, X60, X70 API 5L PLS-2: ISO3183-L245, L290, L320, L360, L415, L485 |

| Insulation | Polyurethane foam (PUR) Nominal Density of 60¹+15-15 kg/m³ | Compressive Strength: ≥ 0.300 Mpa |

| Thermal Conductivity: ≤ 0.029 W/m·K@50ºC | ||

| Closed Cell Content: ≥90% | ||

| Water Absorption: <5% | ||

| Insulation Jacket | High-density polyethylene (HDPE) | As technical parameter |

| Description | polyurethane thermal insulation steel pipe |

| Wall thickness | 0.5mm-16mm |

| Length | 1m-12m or customized |

| Outer Diameter | 0.405-80 inch or 10.3mm – 2032mm |

| Insulation | PUR Foam |

| Operating temperature | Up to 140ºC |

| Standard & Grades | API 5L PSL1/ PSL2, ASTM A53,ASTM A252,GB/T9711.1,GB/T3091,SY/T 5037-2012,DIN1626,EN10219,EN10217 |

| Ends | 30~35° |

| Quality control | 100% X-Ray inspection/ 100%X 100% Hydraulic Pressure test/ 100% 100% Ultrasonic inspection / 100% |

| Lining | Epoxy , cement motar, and according to customers requirement |

| Operating pressure | <1.6Mpa (Equivalent to PN 25? 25bar to be confirmed) |

| Laid way | Buried, overhead, trench |

| Insulation material | Fluoride-Free water foamed rigid polyurethane foam material (foam density: 60kg/m3-80kg/m³) |

| Inner surface tension of the high density polyethylene pipe |

≥50dy/cm |

Conclusion

Polyurethane foam pre-insulated steel pipes offer a highly efficient and reliable solution for thermal insulation in various industries. With superior insulation performance, condensation prevention, and mechanical strength, these pipes contribute to energy conservation, cost savings, and environmental sustainability. Their ease of installation and versatile applications make them suitable for a wide range of projects. By choosing polyurethane foam pre-insulated steel pipes, industries can enhance efficiency, reduce energy losses, and maintain optimal temperature conditions in their pipelines.