301 Stainless Steel Pipes | 300 Series AISI SUS301 Stainless Steel

An In-Depth Analysis of the 301 Stainless Steel Pipe

Introduction

The realm of metallurgy has witnessed a plethora of advancements and innovations, leading to the development of various grades of stainless steel. Among these, the 301 stainless steel pipe has garnered significant attention for its remarkable attributes and diverse applications. This article delves into the intricacies of this exceptional alloy, elucidating its properties, manufacturing process, and potential uses.

|

Product Name

|

Stainless Steel Pipe

|

|

Thickness

|

1-40mm

|

|

Outer Diameter

|

6-630mm

|

|

Length

|

2000mm,2440mm,3000mm,5800mm,6000mm,12000mm etc

|

|

Material

|

310S,310,316,316L,304,304L,201,202,409,409L,410,410S,420,430etc

|

|

Brand Name

|

TISCO,BAO STEEL,ZPSS,LISCO,POSCO,NAS

|

|

Technique

|

Welding and seamless

|

|

Surface

|

Raw,Pickling,Polish,Hairline

|

Composition and Properties

The 301 stainless steel pipe is a versatile and robust alloy, primarily composed of iron, chromium, and nickel. This austenitic stainless steel grade contains approximately 16-18% chromium, 6-8% nickel, and a maximum of 2% manganese, which imparts its distinctive characteristics. The presence of chromium and nickel enhances the alloy’s corrosion resistance, while the addition of manganese improves its strength and ductility.

One of the most notable features of the 301 stainless steel pipe is its exceptional work-hardening capability. This property enables the alloy to be cold-worked extensively, resulting in a significant increase in its yield strength. Furthermore, the 301 stainless steel pipe exhibits excellent toughness, even at sub-zero temperatures, making it suitable for a wide range of applications.

Type 301 Stainless Steel is covered by the following specifications:ASTM A240, ASTM A666.

Chemical Composition:

| Element | Type |

| Carbon | 0.15 max. |

| Manganese | 2.00 max. |

| Sulfur | 0.030 max. |

| Phosphorus | 0.045 max. |

| Silicon | 0.75 max. |

| Chromium | 16.00 – 18.00 |

| Nickel | 6.00 – 8.00 |

| Nitrogen | 0.10 max. |

Mechanical Properties:

| Type | Yield Strength 0.2% offset (KSI) | Tensile Strength (KSI) | % Elongation (2″ Gauge length) | Hardness Rockwell |

| 301 Ann (typical) | 40 | 110 min. | 60 | HRB 85 |

| 301 ¼ Hard | 75 min. | 125 min. | 25 min. | HRC 25 – 32(typical) |

| 301 ½ Hard | 110 min. | 150 min. | 18 min. | HRC 32 – 37(typical) |

| 301 ¾ Hard | 135 min. | 175 min. | 12 min. | HRC 37 – 41(typical) |

| 301 Full Hard | 145 min. | 185 min. | 8 min | HRC 41 – 46(typical) |

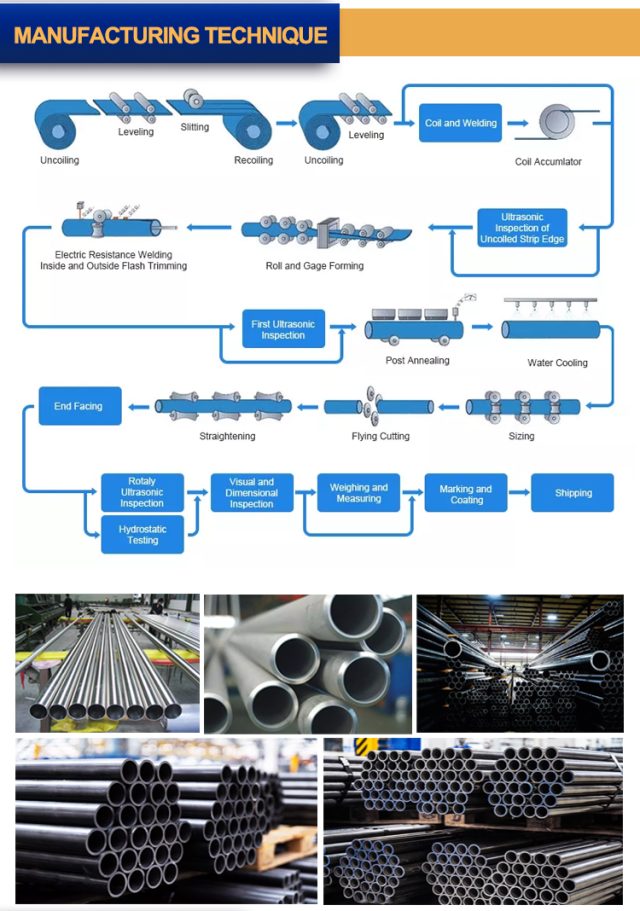

Manufacturing Process

The production of 301 stainless steel pipes commences with the melting of the raw materials, which include iron, chromium, nickel, and other alloying elements. This molten mixture is then cast into billets, which are subsequently hot-rolled into slabs. The slabs undergo a series of cold-rolling processes to achieve the desired thickness and mechanical properties.

Subsequently, the cold-rolled stainless steel is annealed to relieve any residual stresses and enhance its ductility. This process involves heating the material to a specific temperature, followed by controlled cooling. The annealed stainless steel is then pickled to remove any surface oxides and scale, resulting in a clean and smooth surface.

Finally, the 301 stainless steel is formed into pipes using various techniques, such as extrusion, welding, or seamless pipe manufacturing. The choice of method depends on the required dimensions, tolerances, and end-use of the pipes.

Applications

Owing to its remarkable properties, the 301 stainless steel pipe finds extensive use in numerous industries and applications. Some of the most prominent areas of utilization include:

Aerospace: The high strength-to-weight ratio, corrosion resistance, and excellent formability of the 301 stainless steel pipe make it an ideal choice for aircraft structural components, such as airframe sections and landing gear parts.

Automotive: The alloy’s exceptional work-hardening capability and resistance to wear make it suitable for manufacturing various automotive components, including exhaust systems, fuel lines, and trim.

Construction: The 301 stainless steel pipe’s resilience and resistance to environmental factors make it an excellent choice for structural and architectural applications, such as building facades, handrails, and support structures.

Chemical and Petrochemical: The alloy’s resistance to a wide range of chemicals and corrosive environments renders it suitable for use in chemical processing equipment, storage tanks, and piping systems.

Food and Beverage: The hygienic properties and resistance to corrosion of the 301 stainless steel pipe make it an ideal material for food processing equipment, such as conveyors, storage tanks, and piping systems.

How To Identify SUS 301 Stainless Steel Pipe?

To discern the characteristics of SUS 301 stainless steel, one must consider its composition, properties, and various identification methods. SUS 301, an austenitic stainless steel alloy, contains iron, chromium, and nickel, which contribute to its excellent hardening capability, corrosion resistance, and ductility. This versatile material is used in numerous industries, such as aerospace, automotive, construction, chemical and petrochemical, as well as food and beverage.

Several techniques can be employed to identify SUS 301 stainless steel:

Visual Inspection: SUS 301 stainless steel typically exhibits a lustrous, silver-gray appearance. However, this method is not foolproof, as other stainless steel grades may possess a similar appearance.

Chemical Analysis: A more reliable way to identify SUS 301 stainless steel is through chemical analysis. This process involves taking a small sample of the material and determining its chemical composition using techniques such as X-ray fluorescence (XRF) or optical emission spectrometry (OES). The results should align with the standard composition of SUS 301, which consists of approximately 17% chromium, 7% nickel, and a maximum of 0.15% carbon.

Mechanical Properties: Evaluating the mechanical properties of the material, such as tensile strength, yield strength, and elongation, can also help identify SUS 301 stainless steel. These properties can be determined through tensile testing, which involves applying force to a sample until it breaks or deforms. The mechanical properties of SUS 301 stainless steel are distinctive and should align with the standard specifications.

Magnetic Properties: SUS 301 stainless steel exhibits slight magnetic properties when cold-worked or hardened. A magnet can be used to test the material’s magnetic response, but this method should be employed in conjunction with other identification techniques, as other stainless steel grades may also exhibit magnetic properties.

Manufacturer’s Markings: In some cases, the manufacturer may have marked the material with its grade or other identifying information. Inspect the material for any such markings, which can provide valuable information about its composition and properties.

In conclusion, identifying SUS 301 stainless steel requires a combination of visual inspection, chemical analysis, mechanical property evaluation, and magnetic testing. By employing these methods, one can confidently determine the material’s authenticity and suitability for specific applications.

Conclusion

In conclusion, the 301 stainless steel pipe is a remarkable alloy that offers a unique combination of strength, corrosion resistance, and formability. Its diverse applications across various industries stand testament to its versatility and robustness. As the demand for high-performance materials continues to grow, the 301 stainless steel pipe is poised to remain a popular choice for engineers and designers seeking a reliable and efficient solution to their material