A234 WPB grade pipe fittings : Elbows | Tee | Cross | Caps | Reducers

A234 WPB is a grade specification for Buttweld Fittings manufactured from carbon steel and alloy steel. The term “WPB” stands for “wrought pressure vessel quality, grade B.” These fittings are used for pressure piping and for pressure vessel fabrication for service at moderate and elevated temperatures.

The ASTM A234 standard covers the following types of fittings:

- Elbows (45°, 90°, and 180°)

- Tees and Crosses

- Reducers (concentric and eccentric)

- Caps and Stub Ends

- Special Fittings (made as per customer specifications)

The key characteristics of A234 WPB steel pipe fittings include:

- Material Composition: They are made from carbon and alloy steel. The carbon steel may be further classified as per ASTM A 106 and ASTM A 53 or API 5L.

- Resistance: They are resistant to moderate and high-temperature service, making them suitable for many industrial applications that require strength and resistance to stress.

- Manufacturing Process: The manufacturing process of these ASTM A860 WPHY pipe fittings involves shaping the material through a process of heating, then cooling. This process is known as “wrought” which means it’s forged or shaped.

- Uses: They are used in various industrial applications including petrochemical, oil and gas, and power generation due to their strength, flexibility, and resistance to thermal and mechanical stress.

It’s important to note that these fittings must be matched with appropriate pipes in terms of material grade and dimensional specifications to ensure the integrity of the entire piping system. Also, while A234 WPB is a common material grade, other grades can be used based on the specific requirements of the application. ASTM A234 also includes other grades such as WP1, WP5, WP9, WP11, WP22, and more, each with different properties tailored to different applications.

When choosing a pipe fitting, it’s usually important to consider factors such as the material grade, pressure rating, temperature rating, and the application’s specific requirements.

W = WELDABLE / wrought

P = RELATED TO P NUMBER OF ALLOY MATERIAL

B = REFER TO MINIMUM YIELD OF MATERIAL

Chemical Composition (%) of ASTM A234/A234M fittings

| Grade | Type | Chemical Composition (%) | ||||||||||||

| C | Si | S | P | Mn | Cr | Ni | Mo | Other | ób | ós | δ5 | |||

| WPB | 0.3 | 0.1min | 0.058 | 0.05 | 0.29-1.06 | 0.4 | 0.4 | 0.15 | V:0.06;Nb:0.02 | 415-585 | 240 | 22 | 197 | |

| WPC | 0.35 | 0.1min | 0.058 | 0.05 | 0.29-1.06 | 0.4 | 0.4 | 0.15 | V:0.06;Nb:0.02 | 485-655 | 275 | 22 | 197 | |

| WP1 | 0.28 | 0.1-0.5 | 0.045 | 0.045 | 0.3-0.9 | 0.44-0.65 | 380-550 | 205 | 22 | 197 | ||||

| WP12 CL1 | 0.05-0.2 | 0.6 | 0.045 | 0.045 | 0.3-0.8 | 0.8-1.25 | 0.44-0.65 | 415-585 | 220 | 22 | 197 | |||

| WP12 CL2 | 0.05-0.2 | 0.6 | 0.045 | 0.045 | 0.3-0.8 | 0.8-1.25 | 0.44-0.65 | 485-655 | 275 | 22 | 197 | |||

| WP11 CL1 | 0.05-0.15 | 0.5-1 | 0.03 | 0.03 | 0.3-0.6 | 1-1.5 | 0.44-0.65 | 415-585 | 205 | 22 | 197 | |||

| WP11 CL2 | 0.05-0.2 | 0.5-1 | 0.04 | 0.04 | 0.3-0.8 | 1-1.5 | 0.44-0.65 | 485-655 | 275 | 22 | 197 | |||

| WP11 CL3 | 0.05-0.2 | 0.5-1 | 0.04 | 0.04 | 0.3-0.8 | 1-1.5 | 0.44-0.65 | 520-690 | 310 | 22 | 197 | |||

| WP22 CL1 | 0.05-0.15 | 0.5 | 0.04 | 0.04 | 0.3-0.6 | 1.9-2.6 | 0.87-1.13 | 415-585 | 205 | 22 | 197 | |||

| WP22 CL3 | 0.05-0.15 | 0.5 | 0.04 | 0.04 | 0.3-0.6 | 1.9-2.6 | 0.87-1.13 | 520-690 | 310 | 22 | 197 | |||

| WP5 CL1 | 0.15 | 0.5 | 0.03 | 0.04 | 0.3-0.6 | 4-6 | 0.44-0.65 | 415-585 | 205 | 22 | 217 | |||

| WP5 CL3 | 0.15 | 0.5 | 0.03 | 0.04 | 0.3-0.6 | 4-6 | 0.44-0.65 | 520-690 | 310 | 22 | 217 | |||

| WP9 CL1 | 0.15 | 1 | 0.03 | 0.03 | 0.3-0.6 | 8-10 | 0.9-1.1 | 415-585 | 205 | 22 | 217 | |||

| WP9 CL3 | 0.15 | 1 | 0.03 | 0.03 | 0.3-0.6 | 8-10 | 0.9-1.1 | 520-690 | 310 | 22 | 217 | |||

| WPR | 0.2 | 0.05 | 0.045 | 0.4-1.06 | 1.6-2.24 | 435-605 | 315 | 22/28 | 217 | |||||

| WP91 | 0.08-0.12 | 0.2-0.5 | 0.01 | 0.02 | 0.3-0.6 | 8-9.5 | 0.4 | 0.85-1.05 | See sdandard | 585-760 | 415 | 20 | 248 | |

| WP911 | 0.09-0.13 | 0.1-0.5 | 0.01 | 0.02 | 0.3-0.6 | 8.5-10.5 | 0.4 | 0.9-1.1 | See sdandard | 620-840 | 440 | 20 | 248 | |

Notes:

For each reduction of 0.01% below the specified C maximum, an increase of 0.06% Mn above the specified maximum will be permitted, up to a maximum of 1.35%.

The sum of Cu, Ni, Cr, and Mo shall not exceed 1.00%.

The sum of Cr and Mo shall not exceed 0.32%.

The maximum carbon equivalent (C.E.) shall be 0.50, based on heat analysis and the formula C.E.=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15.

Mechanical properties of ASTM A234

| Tensile Requirements | WPB | WPC, WP11CL2 | WP11CL1 | WP11CL3 |

| Tensile Strength, min, ksi[MPa] | 60-85 | 70-95 | 60-85 | 75-100 |

| (0.2% offset or 0.5% extension-under-load) | [415-585] | [485-655] | [415-585] | [520-690] |

| Yield Strength, min, ksi[MPa] | 32 | 40 | 30 | 45 |

| [240] | [275] | [205] | [310] |

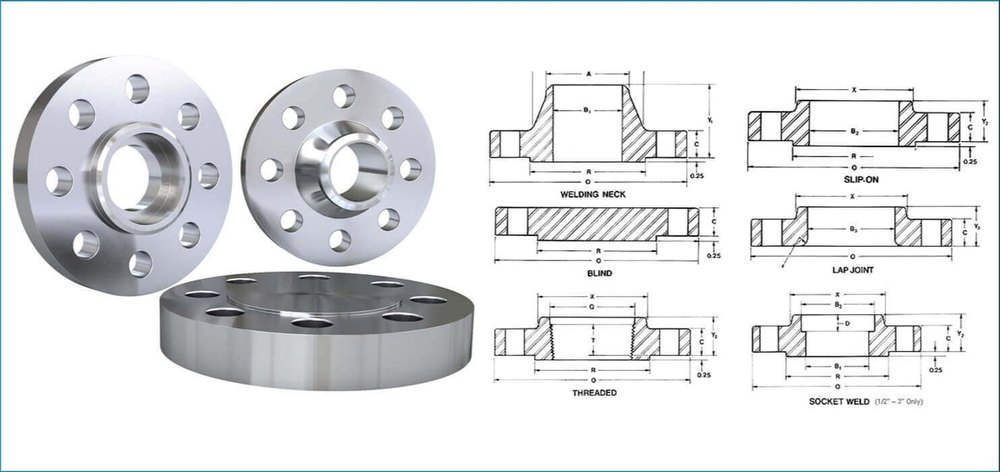

Understanding Flanges: Flanges are mechanical devices used to join pipes, valves, or other equipment. They need to be robust, durable, and resistant to corrosion. Flange Dimensions: The nominal size of a flange should correspond to the bore size of the connecting pipe. The flange rating indicates its pressure and temperature performance.

Stainless Steel 304/304L/304H Buttweld Fittings are versatile fittings known for their high corrosion resistance and superior welding characteristics. The 304/304L/304H versions of stainless steel are variations of a basic 18-8 grade, where 18 represents the chromium percentage and 8 the nickel percentage.

ASMEB 16.5 stainless steel butt weld pipe fittings are vital components in the construction of reliable and efficient piping systems. These fittings, adhering to a recognized standard, provide precise and secure connections between pipes, ensuring a seamless flow of fluids. Whether it is for the oil and gas, chemical processing, or other industries, stainless steel butt weld pipe fittings offer the necessary strength and corrosion resistance to maintain the integrity of piping systems. By selecting high-quality fittings and adhering to the ASMEB 16.5 standard, industries can ensure the efficiency and reliability of their piping systems, contributing to the overall success of their operations.

The Art of Butt Welding Hot Induction Bends: Enhancing Strength and Durability in Pipeline Systems" "Mastering the Technique of Butt Welding Hot Induction Bends: A Comprehensive Guide

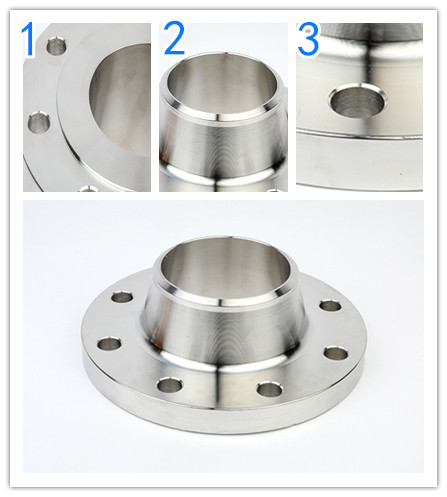

Stainless steel forged butt weld neck flanges are essential components in industrial piping systems. Their strength, durability, and leak-proof design make them suitable for a wide range of applications in various industries. By understanding their features, specifications, and applications, you can make informed decisions when selecting and installing these flanges. Remember to consult industry standards and guidelines for proper installation and maintenance procedures. With the right knowledge and expertise, you can ensure the integrity and efficiency of your piping system with stainless steel forged butt weld neck flanges.

By adding a high amount of metals such as chromium and molybdenum to the 2507 Material, Duplex 2507 Spectacle Bind Spacer Ring becomes extremely resistant to uniform corrosion or General Corrosion, when exposed to environments that contain organic acids like acetic and acetic formic acid. Further, ANSI B16.5 UNS S32750 Flange exhibits excellent resistance to inorganic acids as well, especially in the presence of media that could contain chlorides. Although the ASTM A182 F53 Pipe Flange can be used in dilute hydrochloric acid, exposure to concentrated hydrochloric acid must be avoided. Due to the low carbon content of Duplex Flange, there is a low risk or minimal risk of the occurrence of carbide precipitation at the grain boundaries during heat treatment.