API 5CT L80 Casing and Tubing | L80-1, L80 9Cr, L80 13Cr

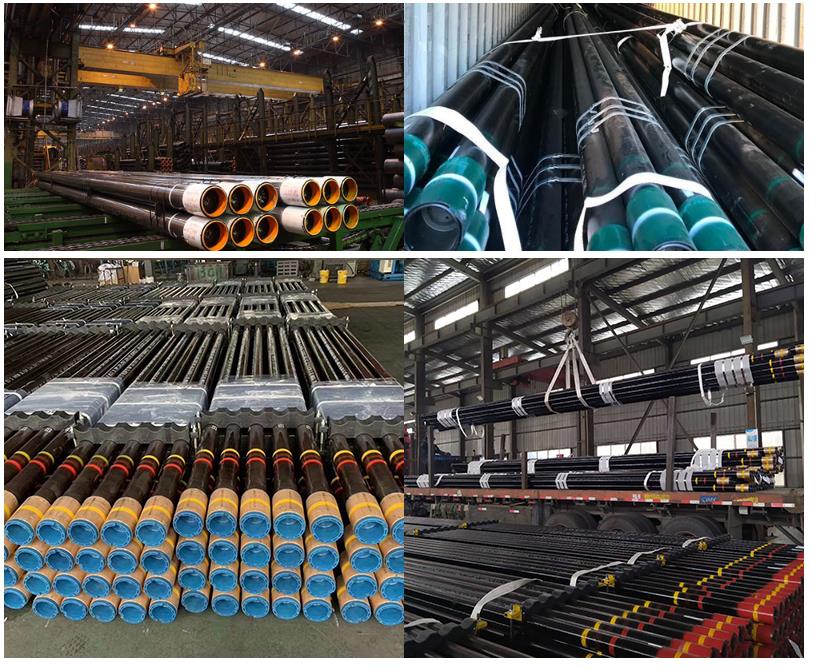

API 5CT L80 Casing and Tubing Pipe

The American Petroleum Institute (API) has developed a variety of standards to ensure the safe and efficient operation of the petroleum and natural gas industries. One such standard is API 5CT, which covers casing and tubing for wells. This guide will delve into the details of the API 5CT L80 grade, a widely-used grade of casing and tubing.

Introduction to API 5CT

API 5CT is a specification for casing and tubing, two critical components in the oil and gas drilling industry. Casing is a large-diameter pipe that is assembled and inserted into a recently drilled section of a borehole and is typically held in place with cement. Tubing, on the other hand, is a pipe through which the oil and gas are transported from the wellbore.

API 5CT L80-13Cr 3-1/2 Inch EUE Tubing

Overview of API 5CT L80

API 5CT L80 is a type of steel grade under API 5CT standard, which is used for oil and gas drilling. The L80 grade is suitable for wells with high sulfur content, offering a balanced combination of strength and corrosion resistance.

This grade is subdivided into three types: L80-1, L80-9Cr, and L80-13Cr.

L80-1

L80-1 is a controlled yield strength material that is primarily used in the oil and natural gas industries for casing and tubing. It is typically used in sour condensate wells due to its high corrosion resistance. The “1” in L80-1 designates the material as Type 1, which has a maximum hardness restriction.

L80-9Cr

L80-9Cr is manufactured with 9% chromium. It is typically used in environments with CO2 due to the material’s resistance to corrosion in such conditions.

L80-13Cr

The L80-13Cr variant is designed with 13% chromium and is intended for use in corrosive environments, particularly those containing CO2.

API 5CT Casing and Tubing Pipe: J55, K55, N80, L80, C95, P10

In the oil and gas industry, casing and tubing play a vital role in ensuring the successful completion of drilling operations and the ongoing efficiency of wells and reservoirs. The API 5CT specification, set forth by the American Petroleum Institute, governs the properties of these essential components, covering a range of steel grades, sizes, and other technical parameters. This article delves into the details of the API 5CT casing and tubing pipe, with specific references to the J55, K55, N80, L80, C95, and P10 grades.

Key Specifications

- Pipe Type: Oil casing, API 5CT casing, API Spec 5CT J55 K55 N80 L80 Casing Pipe, Seamless Steel Oil Well Casing Pipe

- Outer Diameter (OD): 114.30mm-508mm

- Wall Thickness (WT): 5.21mm-16.13mm

- Length: R1, R2, R3

- Grade: J55, K55, N80-Q, L80-1, L80-9Cr, L80-13Cr, C95, P10

- Standard: API 5CT PSL1/PSL2 J55, K55, N80-1, N80-Q, API 5CT PSL1/PSL2 L80-1, L80-9Cr, L80-13Cr, C90, C95, P110, Q125

- Thread Types: STC, LTC, BTC, VAM TOP equivalent, New VAM equivalent, CS equivalent, HSC equivalent, NUE, EUE, LTC, XC

- Thread: NUE, EUE, VAM, STC, LTC, BTC, XC, VAM TOP, NEW VAM, HYDRILL CS

Application

Casing Pipe is widely used for fastening oil and gas well wall or borehole, with a larger diameter than tubing. It includes surface casings, technical casings, and oil layer casings.

Production Technology

The production process includes the following steps:

- Plain pipe-end upsetting

- Austenite treatment

- Quenching

- Tempering

- Straightening

- Non-Destructive Testing

- Threading

- Thread inspection

- Coupling MPI

- Phosphating

- Coupling make up

- Drifting

- Hydrostatic testing

- Measuring & Weight

- Marking & Stenciling

- Coating

- Packing Casing and tubing

- Transportation

Available Sizes

The pipes are available in the following categories:

- ERW

- HFW

- SMLS

Standards and Grades

The applicable standards include H-40, J-55, K-55, C-75, L-80, N-80, C-95, AS-95, P-110, L80-13CR. The steel grades include H40, J55, K55, and N80.

Connections

API 5CT is applicable to the following connections, which comply with API SPEC 5B:

- SC: Short round thread casing

- LC: Long round thread casing

- BC: Buttress thread casing

- NU: Non-upset tubing

- EU: External upset tubing

Manufacturing Process

The API 5CT L80 casing and tubing are manufactured through a seamless process. This process begins with the melting of the steel, followed by the formation of billets. The billets are then heated and stretched into a hollow tube or shell, after which they are further elongated and reduced to the desired dimensions with a series of dies and rolls. The pipes are then cooled and straightened.

Specifications

The API 5CT L80 pipes are available in the R2 length range (8.53-9.75 meters). The outside diameter ranges from 4 1/2 inches to 20 inches, while the thickness ranges from 0.205 to 0.875 inches. These dimensions are quite versatile, making the L80 grade suitable for a variety of applications.

-

Technical parameters of casing pipe:

Sizes OD

D

mmWeight

kg/mWT

t

mmType of end L80

C95N80

1、Q1 2 1 2 3 4 5 9 10 4-1/2

4-1/2

4-1/2

4-1/2

4-1/29.50

10.50

11.60

13.50

15.10114.30

114.30

114.30

114.30

114.3014.14

15.63

17.26

20.09

22.475.21

5.69

6.35

7.37

8.56–

–

PLB

PLB

––

–

PLB

PLB

–5

5

5

5

5

5

511.50

13.00

15.00

18.00

21.40

23.20

24.10127.00

127.00

127.00

127.00

127.00

127.00

127.0017.11

19.35

22.32

26.79

31.85

34.53

35.865.59

6.43

7.52

9.19

11.10

12.14

12.70–

–

PLBE

PLBE

PLB

PLB

PLB–

–

PLBE

PLBE

PLB

PLB

PLBSizes OD

D

mmWeight

kg/mWT

t

mmType of end L80

C95N80

1、Q1 2 1 2 3 4 5 9 10 5-1/2

5-1/2

5-1/2

5-1/2

5-1/2

5-1/2

5-1/2

5-1/2

5-1/2

5-1/2

5-1/2

5-1/214.00

15.50

17.00

20.00

23.00

26.80

29.70

32.60

35.30

38.00

40.50

43.10139.70

139.70

139.70

139.70

139.70

139.70

139.70

139.70

139.70

139.70

139.70

139.7020.83

23.07

25.30

29.76

34.23

39.88

44.20

48.51

52.53

56.55

60.27

64.146.20

6.98

7.72

9.17

10.54

12.70

14.27

15.88

17.45

19.05

20.62

22.22–

–

PLBE

PLBE

PLBE

–

–

–

–

–

–

––

–

PLBE

PLBE

PLBE

–

–

–

–

–

–

–6-5/8

6-5/8

6-5/8

6-5/820.00

24.00

28.00

32.00168.28

168.28

168.28

168.2829.76

35.72

41.67

47.627.32

8.94

10.59

12.06–

PLBE

PLBE

PLBE–

PLBE

PLBE

PLBE7

7

7

7

7

7

717.00

20.00

23.00

26.00

29.00

32.00

35.00177.80

177.80

177.80

177.80

177.80

177.80

177.8025.30

29.76

34.23

38.69

43.16

47.62

52.095.87

6.91

8.05

9.19

10.36

11.51

12.65–

–

PLBE

PLBE

PLBE

PLBE

PLBE–

–

PLBE

PLBE

PLBE

PLBE

PLBE7

7

7

7

7

738.00

42.70

46.40

50.10

53.60

57.10177.80

177.80

177.80

177.80

177.80

177.8056.55

63.54

69.05

74.56

79.77

84.9713.72

15.88

17.45

19.05

20.62

22.22PLBE

–

–

–

–

–PLBE

–

–

–

–

–7-5/8

7-5/8

7-5/8

7-5/8

7-5/8

7-5/8

7-5/8

7-5/8

7-5/8

7-5/824.00

26.40

29.70

33.70

39.00

42.80

45.30

47.10

51.20

55.30193.68

193.68

193.68

193.68

193.68

193.68

193.68

193.68

193.68

193.6835.72

39.29

44.20

50.15

58.04

63.69

67.41

70.09

76.19

82.307.62

8.33

9.52

10.92

12.70

14.27

15.11

15.88

17.45

19.05–

PLBE

PLBE

PLBE

PLBE

PLB

PLB

PLB

–

––

PLBE

PLBE

PLBE

PLBE

PLB

PLB

PLB

–

–7-3/4 46.10 196.85 68.60 15.11 P P 8-5/8

8-5/8

8-5/8

8-5/8

8-5/8

8-5/8

8-5/824.00

28.00

32.00

36.00

40.00

44.00

49.00219.08

219.08

219.08

219.08

219.08

219.08

219.0835.72

41.67

47.62

53.57

59.53

65.48

72.926.71

7.72

8.94

10.16

11.43

12.70

14.15–

–

–

PLBE

PLBE

PLBE

PLBE–

–

–

PLBE

PLBE

PLBE

PLBE9-5/8

9-5/8

9-5/8

9-5/8

9-5/8

9-5/8

9-5/8

9-5/8

9-5/8

9-5/8

9-5/832.30

36.00

40.00

43.50

47.00

53.50

58.40

59.40

64.90

70.30

75.60244.48

244.48

244.48

244.48

244.48

244.48

244.48

244.48

244.48

244.48

244.4848.07

53.57

59.53

64.73

69.94

79.62

86.91

88.40

96.58

104.62

112.507.92

8.94

10.03

11.05

11.99

13.84

15.11

15.47

17.07

18.64

20.24–

–

PLBE

PLBE

PLBE

PLBE

PLB

–

–

–

––

–

PLBE

PLBE

PLBE

PLBE

PLB

–

–

–

–10-3/4

10-3/4

10-3/4

10-3/4

10-3/4

10-3/4

10-3/432.75

40.50

45.50

51.00

55.50

60.70

65.70273.05

273.05

273.05

273.05

273.05

273.05

273.0548.74

60.27

67.71

75.90

82.59

90.33

97.777.09

8.89

10.16

11.43

12.57

13.84

15.11–

–

–

PSBE

PSBE

–

––

–

–

PSBE

PSBE

–

–10-3/4

10-3/4

10-3/473.20

79.20

85.30273.05

273.05

273.05108.93

117.86

126.9417.07

18.64

20.24–

–

––

–

–11-3/4

11-3/4

11-3/4

11-3/4

11-3/4

11-3/442.00

47.00

54.00

60.00

65.00

71.00298.45

298.45

298.45

298.45

298.45

298.4562.50

69.94

80.36

89.29

96.73

105.668.46

9.53

11.05

12.42

13.56

14.78–

–

–

PSB

P

P–

–

–

PSB

P

P13-3/8

13-3/8

13-3/8

13-3/8

13-3/848.00

54.50

61.00

68.00

72.00339.72

339.72

339.72

339.72

339.7271.43

81.10

90.78

101.19

107.158.38

9.65

10.92

12.19

13.06–

–

–

PSB

PSB–

–

–

PSB

PSB16

16

16

1665.00

75.00

84.00

109.00406.40

406.40

406.40

406.4096.73

111.61

125.01

162.219.53

11.13

12.57

16.66–

–

–

P–

–

–

P18-5/8 87.50 473.08 130.21 11.05 – – 20

20

2094.00

106.50

133.00508.00

508.00

508.00139.89

158.49

197.9311.13

12.70

16.13–

–

––

–

–Remarks: P——Plain end;S—Short round thread;L—Long round thread;B—Buttress thread;E—Extreme-line. Note: other premium connection shall be provided as per customer requirements.

Chemical compositions of casing pipe

Chemical compositions of casing pipe Standard Grade Chemical compositions(%) API SPEC 5CT N80 0.34~0.38 0.20~0.35 1.45~1.70 ≤0.020 ≤0.015 ≤0.15 / / / 0.11~0.16 L80 0.15~0.22 ≤1.00 0.25~1.00 ≤0.020 ≤0.010 12.0~14.0 ≤0.20 ≤0.20 / / Mechanical properties of casing pipe

Mechanical properties of casing pipe Grade Type Total elongation Yield strength Yield strength Tensile strength Hardness Hardness under load (min)Mpa (max)Mpa min Mpa Max (HRC) Max (HBW) (%) N80 1 0.5 552 758 689 – – N80 Q 0.5 552 758 689 – – L80 1 0.5 552 655 655 23 241 L80 9Cr 0.5 552 655 655 23 241 L80 13Cr 0.5 552 655 655 23 241

Applications

API 5CT L80 casing and tubing are primarily used in oil drilling, oil well wall support, and the construction of oil extraction platforms. These pipes ensure that the walls of the drilled hole, or wellbore, remain intact during drilling. They also provide good sealing and protection from contaminants, reducing the risk of damaging the oil and gas reservoir.

In sour service and high-temperature wells, the L80 grade’s corrosion resistance properties make it particularly useful.

Conclusion

The API 5CT L80 casing and tubing pipe is a vital component in the oil and gas extraction industry. Its excellent performance under harsh conditions ensures the safe and efficient operation of drilling activities. Engineers must select the appropriate grade based on the specific requirements of the application and the environment in which it will be used. With the correct selection and use, these pipes can contribute significantly to the longevity and reliability of the entire system.