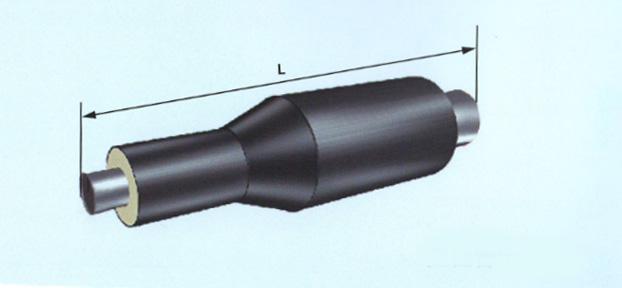

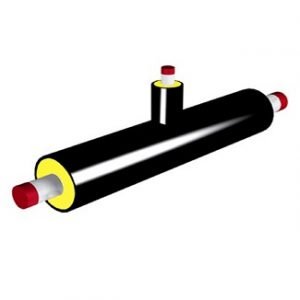

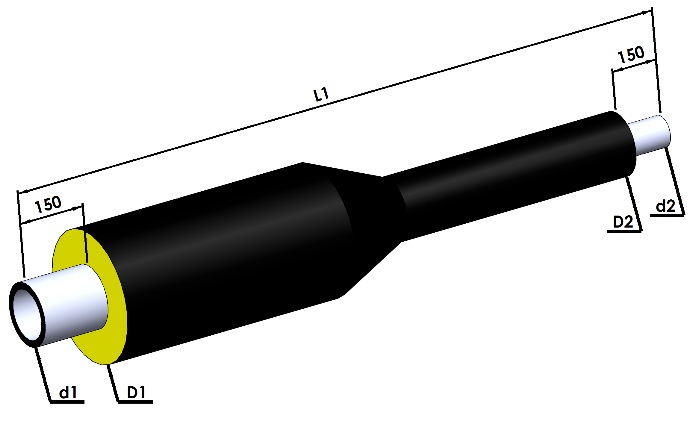

Pre-insulated steel reducer

A pre-insulated steel reducer is a type of pipe fitting that is used in a pipe system to reduce its size from one location to another. It’s used in pre-insulated piping systems where there is a need to connect two pipes of different diameters while maintaining the thermal insulation properties of the system.

The reducer consists of three primary components:

Steel Reducer: This is the innermost component that provides the actual reduction in pipe size. It’s typically made from carbon steel or stainless steel and is designed to withstand the pressure and temperature of the fluid being transported.

Insulation Layer: Surrounding the steel reducer is a layer of insulation, often made from polyurethane foam. This layer provides thermal insulation, reducing heat loss (or gain, in the case of cooling systems) and thereby increasing the energy efficiency of the system.

Outer Jacket: The outermost layer is typically a casing made of high-density polyethylene (HDPE). This casing provides mechanical protection for the insulation and the steel reducer, as well as acting as a barrier to moisture and other environmental conditions.

It’s worth noting that the specific design and materials used for a pre-insulated steel reducer may vary based on the requirements of the specific application, including the operating temperature and pressure, the type of fluid being transported, and the environmental conditions. As with any component in a piping system, a pre-insulated steel reducer should be installed and maintained in accordance with the manufacturer’s instructions to ensure its longevity and performance.

| Product Indexes | Reference Standard | Standard Requirement | Our product value |

| Outer protection pipe | |||

| Density (kg/m3 ) | CJ/T114-4.2.3.1 | ≥940 | 948.2 |

| Elongation at break (%) | CJ/T114-4.2.3.4 | ≥350 | 618 |

| Tensile yield strength (MPa) | CJ/T114-4.2.3.4 | ≥19 | 20.5 |

| Longitudinal shrinkage rate (%) | CJ/T114-4.2.3.5 | ≤3 | 1.23 |

| Long term Mechanical properties | CJ/T114-4.2.3.6 | >1500h(80℃, 4.0 MPa)free from damage | Pass |

| The difference of the melt flow rate (g/10min) | CJ/T114-4.2.3.2 | ≤0.5 | 0.11 |

| Carbon Black Content % | CJ/T114-4.2.3.1 | 2.5±0.5 | 2.4 |

| Polyurethane insulation layer | |||

| Density (kg/m³) | CJ/T114-4.3.2 | ≥60 | 71.1 |

| Average pore size (mm) | CJ/T114-4.3.1 | ≤0.5 | qualified |

| Percentage of close area(%) | CJ/T114-4.3.1 | ≥88 | 94 |

| Compressive strength(MPa) | CJ/T114-4.3.3 | ≥0.3 | 0.58 |

| Water absorption(%) | CJ/T114-4.3.4 | Immersion in boiling water 90 minutes, bubble water absorption should be not more than 10% | ≤5.53 |

| Working steel pipe | |||

| Seamless steel pipe(≤DN150) | GB8163 | 20# | qualified |

| Spiral steel pipe(≥DN200) | GB/T9711 or SY/T5037 | Q235B | qualified |

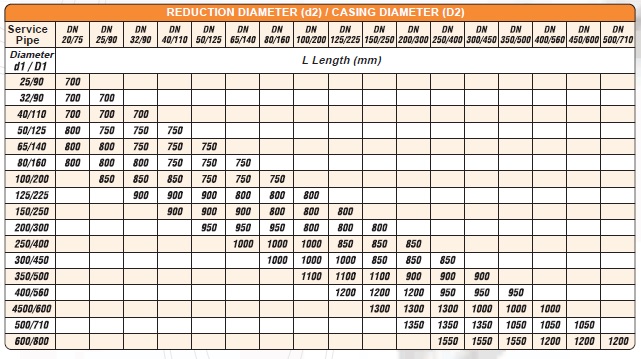

| Insulation Reducer | ||

| No. | Norminal diameter DNXDN(mm) | L(mm) |

| 1 | 50×40 | 1080 |

| 2 | 70×50 | 1080 |

| 3 | 80x(50~70) | 1100~1090 |

| 4 | 100x(50, 70, 80) | 1080, 1090, 1100 |

| 5 | 125x(70~100) | 1100 |

| 6 | 150x(80~125) | 1190 |

| 7 | 250x(100~200) | 1190~1300 |

| 8 | 300x(125~300) | 1250~1450 |

| 9 | 350x(150~300) | 1250~1500 |

| 10 | 400x(200~350) | 1250~1550 |

| 11 | 450x(250~400) | 1250~1550 |

| 12 | 500x(300~450) | 1250~1550 |

| 13 | 600x(350~500) | 1250~1550 |

| 14 | 700x(400~600) | 1450~1750 |

| 15 | 800x(450~700) | 1450~1850 |

| 16 | 900x(500~800) | 1550~2050 |

| 17 | 1000x(600~900) | 1550~2150 |

| 18 | 1200x(700~1000) | 1550~2150 |