ASTM A519 Seamless Steel Mechanical Pipe, Cylinder tube

what is A519 steel mechanical Pipe , and mechanical properties

A519 steel is a type of seamless carbon and alloy steel mechanical tubing that is commonly used in applications where high mechanical strength and uniformity are required. It is produced according to the ASTM A519 specification, which is a standard established by the American Society for Testing and Materials (ASTM).

The mechanical properties of A519 steel can vary depending on the specific grade of steel being used. There are various grades available, each offering different chemical compositions and mechanical properties. Some of the common grades include 1020, 1026, 4130, and 4140.

Here are the typical mechanical properties of ASTM A519 steel:

- Tensile Strength: This is the amount of tensile stress that the steel can withstand before breaking. The tensile strength varies depending on the grade, with higher grades generally offering greater tensile strength. For example, the tensile strength of A519 grade 1020 is approximately 420 MPa, while the tensile strength of A519 grade 4130 can range from 670 to 930 MPa.

- Yield Strength: This is the amount of stress that the steel can withstand without undergoing permanent deformation. Like tensile strength, yield strength also varies depending on the grade of steel. For instance, the yield strength of A519 grade 1020 is around 350 MPa, while for A519 grade 4130, it can range from 460 to 630 MPa.

- Elongation: This is the measure of the steel’s ability to be stretched without breaking. It is expressed as a percentage of the original length. Elongation varies with the grade of steel, but generally, higher grades have a lower elongation percentage. For A519 grade 1020, the elongation is around 25%, while for A519 grade 4130, it can be around 17%.

- Hardness: This refers to the steel’s resistance to indentation and is usually measured using the Brinell or Rockwell hardness scales. Hardness values can vary depending on the grade and heat treatment, but generally, higher grades have greater hardness. For example, A519 grade 1020 has a Brinell hardness of approximately 121, while A519 grade 4130 can have a Brinell hardness ranging from 217 to 235.

These mechanical properties make A519 steel suitable for various applications, such as automotive parts, hydraulic cylinders, and machinery components. However, it is essential to choose the appropriate grade of A519 steel based on the specific requirements of the application to ensure optimal performance.

| Material Chemical Compostion(%) | |||||||||

| Standard | Steel Grade | Material Number | C | Si | Mn | P | S | Cr | Mo |

| ASTM A519 | 1010 | – | 0.08-0.13 | – | 0.3-0.6 | ≤0.04 | ≤0.05 | – | – |

| 1020 | – | 0.18-0.23 | – | 0.3-0.6 | ≤0.04 | ≤0.05 | – | – | |

| 1045 | – | 0.43-0.50 | – | 0.6-0.9 | ≤0.04 | ≤0.05 | – | – | |

| 4130 | – | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.04 | ≤0.04 | 0.8-1.1 | 0.15-0.25 | |

| 4140 | – | 0.38-0.43 | 0.15-0.35 | 0.75-1.0 | ≤0.04 | ≤0.04 | 0.8-1.1 | 0.15-0.25 | |

| CW | SR | A | N | ||||||

| Rm Tensile Strengh (Mpa) Min | A Elongation(%) Min | Rm Tensile Strengh (Mpa) Min | A Elongation(%) Min | Rm Tensile Strengh (Mpa) Min | Rel Yield Strength (Mpa) Min | A Elongation(%) Min | Rm Tensile Strengh (Mpa) Min | Rel Yield Strength (Mpa) Min | A Elongation(%) Min |

| 450 | 6 | 420 | 16 | 310 | 170 | 35 | 360 | 215 | 24 |

| 483 | 5 | 448 | 10 | 331 | 193 | 30 | 379 | 234 | 22 |

| 621 | 5 | 552 | 8 | 448 | 241 | 20 | 517 | 331 | 15 |

| – | – | 724 | 10 | 517 | 379 | 30 | 621 | 441 | 20 |

| – | – | 855 | 10 | 552 | 414 | 25 | 855 | 621 | 20 |

what is A519 steel mechanical Pipe application

ASTM A519 steel mechanical tubing is used in various industries due to its excellent mechanical properties and uniformity. These tubes are widely employed in applications that demand high strength, toughness, and resistance to wear. Some common applications of A519 steel mechanical pipes include:

- Automotive Components: A519 steel tubes are used in the manufacture of various automotive parts, such as axles, drive shafts, and gears, due to their high strength and durability.

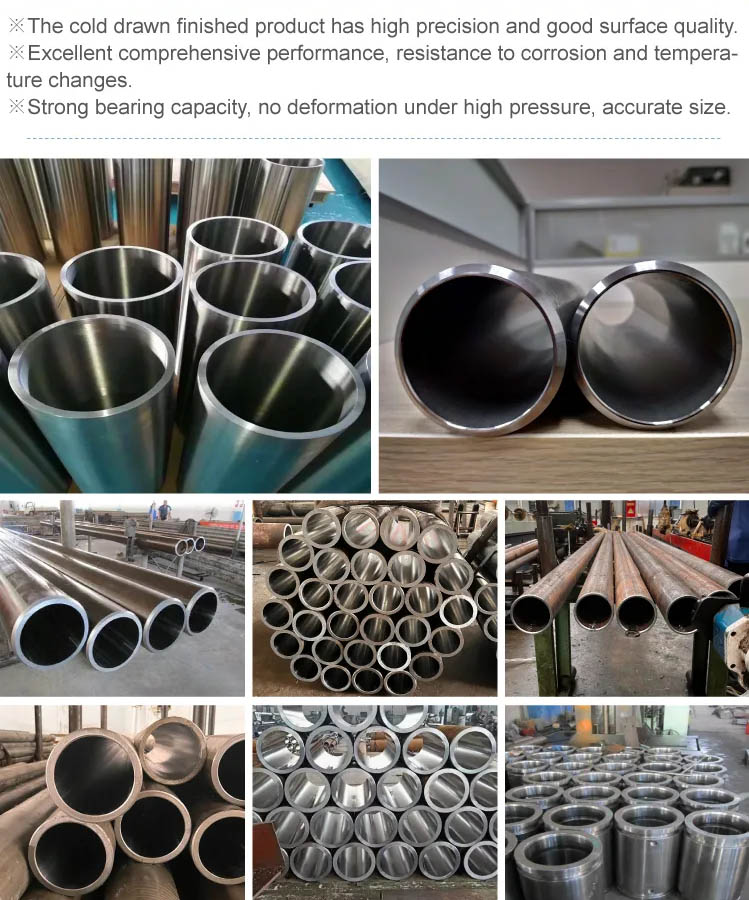

- Hydraulic Cylinders: The uniformity and precision of A519 steel tubes make them suitable for the production of hydraulic cylinders, which require tight tolerances and high-strength materials.

- Machinery Components: A519 steel mechanical tubes are used in various machinery components, such as rollers, bearings, and bushings, due to their high load-bearing capacity and resistance to wear.

- Aerospace Industry: In the aerospace industry, A519 steel tubes are used to manufacture high-strength components, such as landing gear struts and structural elements, that can withstand high stress and fatigue.

- Oil and Gas Industry: A519 steel tubes are utilized in the oil and gas industry for the manufacturing of drill collars, drill pipes, and other drilling equipment components that require high strength and resistance to wear and corrosion.

- Heavy Equipment: A519 steel tubes are also used in the production of heavy equipment, such as cranes, tractors, and bulldozers, where high-strength materials are crucial for structural integrity and durability.

- Sporting Equipment: Some sporting equipment, like bicycle frames and components, also use A519 steel tubes due to their high strength-to-weight ratio and fatigue resistance.

Please note that the specific grade of A519 steel should be selected based on the requirements of the application, as different grades have different chemical compositions and mechanical properties. This ensures optimal performance and durability in the intended use.

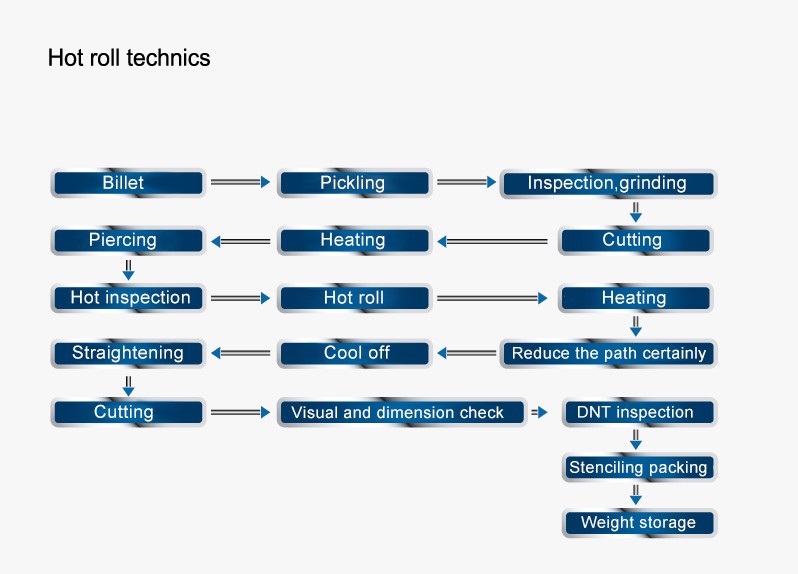

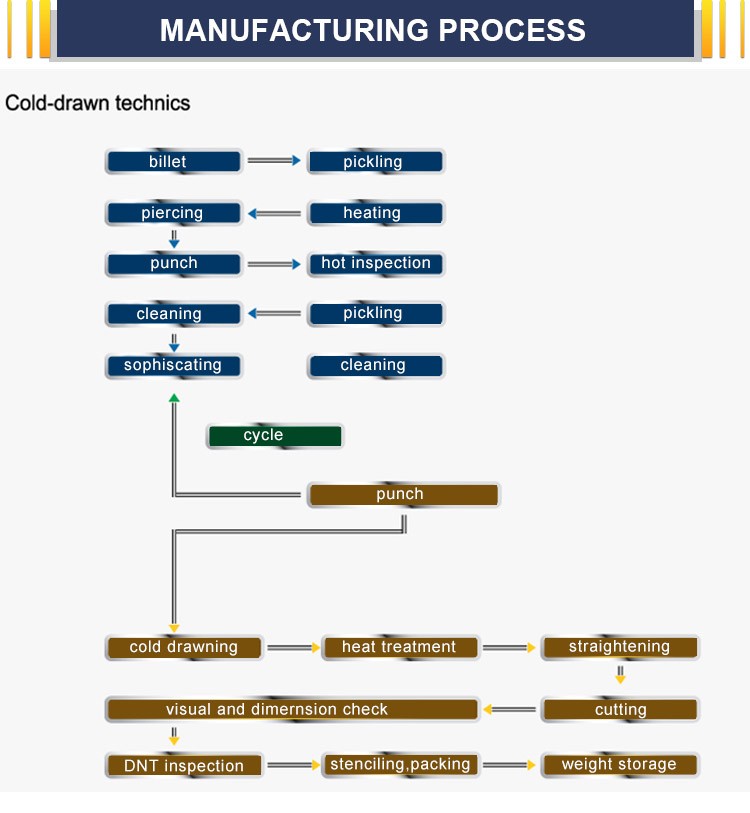

ASTM A519 seamless steel pipe manufacturing process