DIN 17175 Steel Pipe for boilers | heat exchanger tubes | high temperatures and pressures

what is the DIN 17175 Steel Pipe?

DIN 17175 steel pipe is a German standard that specifies seamless tubes made of heat-resistant steels, designed primarily for high-pressure applications. These steel pipes are manufactured from carbon and alloy steel grades, which can endure high pressure and temperature conditions. The main purpose of DIN 17175 steel pipes is to be used in boiler installations, high-pressure pipelines, and tank construction where high temperatures and pressures are involved.

Some key characteristics and uses of DIN 17175 steel pipes are:

- High heat and pressure resistance: DIN 17175 steel pipes are designed to withstand high temperatures and pressures, making them suitable for demanding applications.

- Good mechanical properties at elevated temperatures: The steel grades used in DIN 17175 pipes exhibit excellent mechanical properties when exposed to high temperatures, ensuring the pipes’ durability and reliability.

- Wide range of applications: DIN 17175 steel pipes are commonly used in various high-temperature applications, such as power generation, petrochemical, and chemical industries.The pipes under DIN 17175 are manufactured from carbon and low-alloy steel grades which are resistant to loads under high pressure and temperatures. They are used for the construction of power engineering appliances such as: boilers, heating coils, stoves, heaters, heat exchanger tubes.

The main steel grades used in DIN 17175 steel pipes are:

-

- St35.8

- St45.8

- 17Mn4

- 19Mn5

- 15Mo3

- 13CrMo44

- 10CrMo910

- 14MoV63

- X20CrMoV121

These steel grades have different chemical compositions and mechanical properties, making them suitable for different applications and operating conditions. The appropriate steel grade should be chosen based on the specific requirements of your project.

DIN 17175 steel pipes are available in various sizes and thicknesses and can be supplied with plain ends, beveled ends, or threaded ends, depending on the customer’s requirements. To ensure high quality, these pipes are usually subject to non-destructive testing, such as ultrasonic testing, eddy current testing, and radiographic testing.

When using DIN 17175 steel pipes in your project, it’s essential to consult with an engineer or a professional who can guide you on the right material selection and installation practices. Additionally, make sure to adhere to the relevant safety standards and regulations when working with high-pressure equipment.

DIN 17175 Chemical Composition:

| DIN 17175 Steel Grade | C | Si | Mn | P | S | Cr | Mo | Ni% max |

|---|---|---|---|---|---|---|---|---|

| St35.8 | ≤0.17 | 0.10-0.35 | 0.40-0.80 | ≤0.040 | ≤0.040 | / | / | – |

| St45.8 | ≤0.21 | 0.10-0.35 | 0.40-1.20 | ≤0.040 | ≤0.040 | / | / | – |

| 15Mo3 | 0.12-0.20 | 0.10-0.35 | 0.40-0.80 | ≤0.035 | ≤0.035 | / | 0.25-0.35 | 0,25- 0,35 |

| 13CrMo44 | 0.10-0.18 | 0.10-0.35 | 0.40-0.70 | ≤0.035 | ≤0.035 | 0.70-1.10 | 0.46-0.65 | 0.45- 0.65 |

| 10CrMo910 | 0.08-0.15 | ≤0.50 | 0.40-0.70 | ≤0.035 | ≤0.035 | 0.20-0.25 | 0.90-1.20 | 0.90- 1.20 |

DIN 17175 Mechanical Property:

| DIN 17175 Steel Grade | Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation(%) |

|---|---|---|---|

| St35.8 | ≥235 | 360-480 | 25 |

| St45.8 | ≥255 | 410-530 | 21 |

| 15Mo3 | ≥275 | 450-600 | 20 |

| 13CrMo44 | ≥290 | 440-590 | 20 |

| 10CrMo910 | ≥280 | 450-600 | 18 |

DIN 17175 Equivalent Steel Grade:

| OLD | New | ||||

|---|---|---|---|---|---|

| Execution | Norm | Steel grade | Execution | Norm | Steel grade |

| Welded | DIN 1626 | St.37.0 | Welded | DIN EN 10217-1 | P235TR2 |

| Welded | DIN 1626 | St.52.2 | Welded | DIN EN 10217-3 | P355N |

| Seamless | DIN 1629 | St.37.0 | Seamless | DIN EN 10216-1 | P235TR2 |

| Seamless | DIN 1629 | St.52.2 | Seamless | DIN EN 10216-3 | P355N |

| Seamless | DIN 17175 | St.35.8/1 | Seamless | DIN EN 10216-2 | P235GH |

| Seamless | ASTM A106* | Grade B | Seamless | DIN EN 10216-2 | P265GH |

| Seamless | ASTM A333* | Grade 6 | Seamless | DIN EN 10216-4 | P265NL |

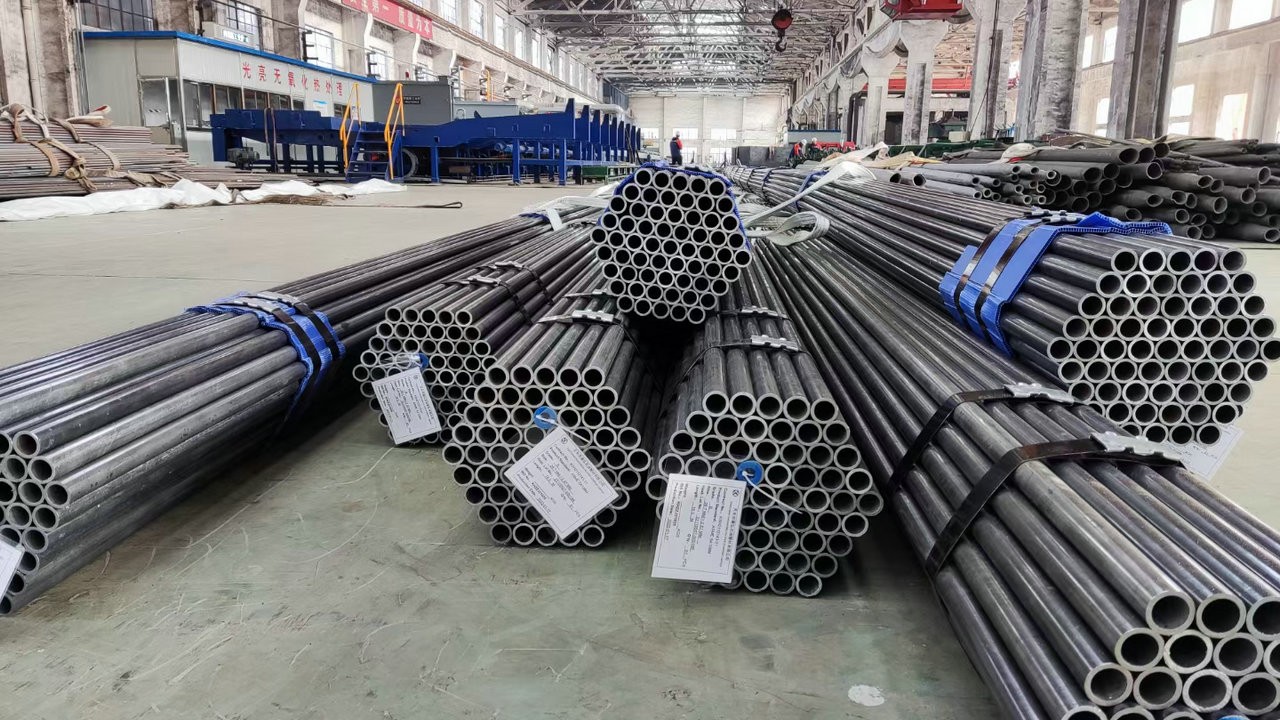

DIN 17175 seamless steel pipes are used for boiler installations, high-pressure pipelines and tank construction and special machinery for both high temperature and high-pressure devices(Above 450° high temperature). ABTER STEEL is an experienced boiler and pressure steel tube supplier which can offer you DIN 17175 steel pipe of all grade and dimension range.

2 comments

pontificd

2024年1月1日 at pm8:34

What is DIN 17175 material?

Ronsun2023

2024年1月8日 at pm8:50

DIN 17175 Grade St 45-8 Tubes, are low-cost Low Carbon Steel Tubes with max 021 % carbon content with combination of 040-120 % manganese easy to form and shape . These pipes are manufactured as per DIN Specification and commercially referred as cs pipes or ms pipes.