EN253 steel coated insulation pipe | EN253 Hot water pipes

Thermal Insulated EN253 steel PU foam coated insulation pipe

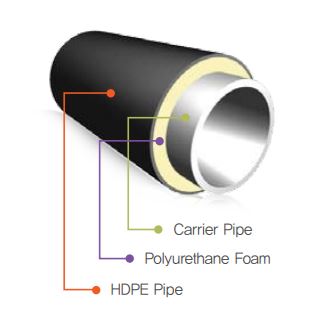

EN 253 is a European standard for pre-insulated pipes used in district heating systems. These pipes are designed to maintain the temperature of the fluid being transported over long distances. Here’s a breakdown of the structure of a typical EN 253 steel pipe with polyurethane (PU) foam insulation:

- Service Pipe: This is the innermost layer made of steel. It transports the hot or cold water/other fluids. The steel pipe should be designed to withstand the pressure and temperature of the fluid being transported.

- Insulation Layer: Surrounding the service pipe is a layer of rigid polyurethane foam. PU foam has excellent thermal insulation properties, which reduces heat loss or gain and makes the system more energy-efficient. This ensures that the fluid being transported maintains its temperature over long distances.

- Outer Jacket/Barrier Pipe: The outermost layer is often made of high-density polyethylene (HDPE). This protective layer shields the insulation from mechanical damage, moisture, and other environmental factors.

In addition, some systems also have a layer of surveillance (leak detection) or alarm system between the service pipe and the insulation layer. This system can provide early warning if the pipe leaks, thereby minimizing damage and downtime.

The EN 253 standard also provides requirements for the testing, marking, and quality control of these pre-insulated pipe systems. These include tests for dimensions, thermal conductivity, and creep behavior, among others.

The exact specifications will depend on the requirements of the specific district heating or cooling system, so it’s always best to consult with a manufacturer or supplier for detailed information.

EN 253 pre-insulated steel pipes are typically used for district heating and cooling systems. These are systems that distribute heat or coolants generated in a centralized location for residential and commercial heating or cooling.

EN253 pre-insulated steel pipe use for?

Here are the main applications:

- District Heating Systems: In these systems, a central plant produces hot water or steam, which is then distributed to buildings in the area through a network of pre-insulated pipes. The insulation helps to minimize heat loss during transit, making the system more energy-efficient.

- District Cooling Systems: Similarly, district cooling systems distribute chilled water from a central plant to buildings for air conditioning. Again, the insulation helps to prevent heat gain during transit.

- Industrial Applications: Pre-insulated pipes can also be used in a variety of industrial applications, where a fluid needs to be transported at a stable temperature over a relatively long distance. This can include oil and gas industries, chemical industries, and more.

The benefit of using pre-insulated pipes, such as those conforming to EN 253, in these applications is that they are highly efficient in terms of energy loss. The insulation layer, usually made of polyurethane foam, minimizes heat loss (or gain, in cooling applications), which can lead to significant energy savings. The outer jacket also provides excellent protection against mechanical damage and the environment, which can extend the service life of the pipeline system.

| Standard | EN 253 |

| Processing ability | OD:38mm-1620mm;WT:2mm-30mm |

| Length | 6-14m |

| Packing | PE/BE,plastic cap,bundling |

| Technique | External surface on welded pipe or seamless pipe |

| Application | Insulation and cold insulation pipeline |

| Service condition | Salt,alkaline or sour;underground |

| Place of origin | China |

| MOQ | 30 pieces |

| The minimum thickness of protective layer and insulation layer | |||

| for conveying the media below 100℃ (mm) | |||

| Forming Process | Outer Diameter | Axial eccentricity | The minimum thickness of protective layer |

| One-stop Method | 48mm-144mm | ±3 | ≥1.4 |

| 159mm-377mm | ±5 | 1.6 | |

| >377mm | ±5 | 1.8 | |

| Pipe-in-pipe | ≤159mm | ±3 | 2 |

| 168mm-245mm | ±4 | 3 | |

| 273mm-377mm | 4 | ||

| ≥ 426mm | ±5 | 4.5 | |

| Outer diameter and the minimum wall thickness of protection pipe of insulation pipe for conveying media between 100℃~120℃ (mm) | |||||||||||

| OD | 110 | 125 | 140 | 160 | 200 | 225 | 250 | 280 | 315 | 355 | 365 |

| Min.WT | 2.5 | 3 | 3.2 | 3.5 | 3.9 | 4.4 | 4.9 | 5.6 | |||

| OD | 400 | 420 | 450 | 500 | 550 | 560 | 630 | 655 | 710 | 760 | 850 |

| Min.WT | 6.3 | 7 | 7.8 | 8.8 | 9.8 | 11.1 | 12 | ||||

| OD | 950 | 955 | 995 | 1045 | 1155 | 1200 | |||||

| Min.WT | 12 | 13 | 12 | 13 | 14 | 14 | |||||

| Note: Other protection pipes can be used according to the customers’ requirements, but the minimum thickness of protection pipes should be sure as per interpolation method in the table above. | |||||||||||