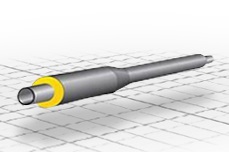

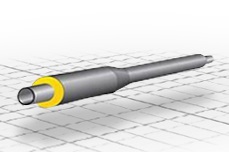

The production of Electric Resistance Welded (ERW) pipes and Spiral Arc Welded (SAW) steel pipes is in accordance with the EN 10217.1 standard. Steel drawn pipes, stainless steel pipes, copper pipes, high-density polyethylene (HDPE100) pipes, PPR, PPR-C, CTP (glass fiber reinforced polyester pipe), and CTE (glass fiber reinforced epoxy pipe) are produced following the EN 10216.1 standard. These pipe types can serve as service pipes.

As a protective cover, a UV compounded, black, high-density PE100 casing pipe is used, with a density greater than 940 kg/m3. The specifications and sizes of these high-density, seamless polyethylene pipes adhere to the TS EN 253 standard. The casing remains attached to the pipe due to the corona process, ensuring permanent connections with PUR rigid foam.

Insulation is provided by polyurethane, specifically polyurethane rigid foam, which includes compound A (polyol) and compound B (isocyanate). This can be continuously processed with heat conductivity of 0.0274 W/(mK) or 0.0275 W/(mK), as per the TS EN 253 standard. The foam has a minimum density of 60 kg/m3 and can handle fluid temperatures up to 120℃, with occasional peak fluid temperatures of 140℃. The heat conductivity coefficient remains constant throughout the insulation’s lifespan (at least 30 years), resulting in minimal heat loss and stable operating costs. Its installation is straightforward, saving time and labor, and reducing workmanship errors. It doesn’t require a gallery and can be buried underground.

The use of extension elements (compensators) is either eliminated or minimized due to the manufacturing technique. In gallery applications that are over console, bearers are applied on the external casing, preventing the formation of heat foams. The service pipe and cover pipe can be made of different materials depending on the project. Pipe lengths can be manufactured at 6, 8, or 12 meters, depending on the diameter. Production can include an observation wire to comply with the leakage observation system.

Front Isolated Geothermal Pipe Inserts

Relationship Between Estimated Life and Continuous Operating Temperature