Pre-Insulated Tee | HDPE Jacketed Pre-Insulated Rising Tee

.

- APPLICATION:

- Chilled Water, Condenser Water, Domestic Water, Potable Water, Waste Water

- INSULATION:

- Polyurethane Form

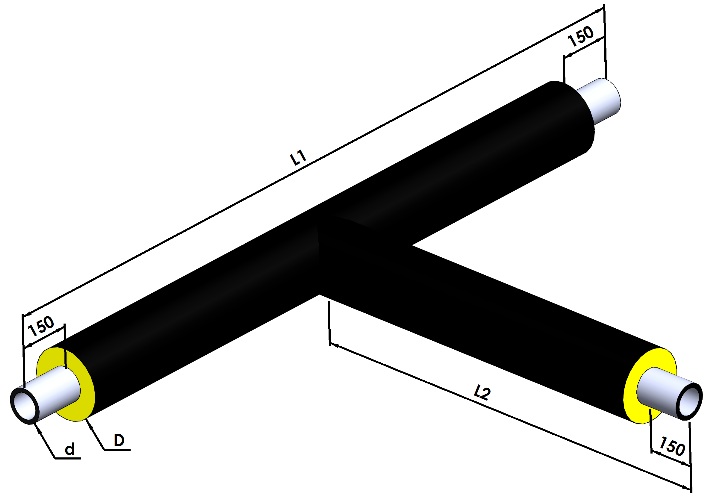

A pre-insulated steel tee is a type of pipe fitting used in various piping systems, particularly in HVAC (Heating, Ventilation, and Air Conditioning) applications. It is designed to provide a connection point for branching off a main pipeline while also incorporating insulation to minimize heat loss or gain.

The tee itself is typically made of steel, which offers excellent strength and durability. It is commonly used in industrial and commercial settings where the piping system needs to withstand high pressures and temperatures. The steel tee is manufactured with precision to ensure proper alignment and sealing when connected to other pipes.

The insulation component of a pre-insulated steel tee is what sets it apart from a regular tee. It is typically made of foam or other insulating materials that are selected based on the specific requirements of the application. The insulation is applied around the exterior of the steel tee, providing a protective barrier that helps prevent heat transfer between the fluid flowing inside the pipe and the surrounding environment.

The pre-insulated steel tee offers several advantages in HVAC systems. By minimizing heat loss or gain, it helps improve energy efficiency and reduces the operating costs associated with heating or cooling. It also helps maintain a consistent temperature within the piping system, which is crucial for applications where temperature control is critical.

Additionally, the insulation layer of a pre-insulated steel tee provides protection against condensation and prevents the formation of moisture on the outer surface of the pipe. This helps prevent corrosion and prolongs the lifespan of the piping system.

Overall, pre-insulated steel tees are commonly used in HVAC applications where thermal efficiency, temperature control, and corrosion resistance are important factors. They provide a convenient and reliable solution for branching off piping systems while ensuring optimal insulation performance.