Zinc Coated Galvanized Steel Pipe

Zinc coated galvanized steel pipes are a type of steel pipe that have been coated with a layer of zinc to help prevent corrosion. The process of galvanizing involves the application of a zinc layer to a steel pipe through either hot-dip galvanization or electro-galvanization.

Hot-Dip Galvanization

In the hot-dip galvanization process, the steel pipe is dipped into a bath of molten zinc. This process allows the zinc to form a metallurgically bonded coating that is highly resistant to wear and weathering. The thickness of the zinc layer can be controlled by the duration of immersion in the bath and the thickness of the original steel.

| Thickness | 1-200mm;or as required | Length: | 2000-16000mm,or as required |

| Dimensions | 16-1020mm;(1/2inch~40inch)Dimensions | Technique | Hot Rolled Or Cold Rolle |

| Zinc Coating | pre galvanized steel pipe: 60-150g/m2 hot dipped galvanized steel pipe:200-460g/m2 |

Surface treatment | Cold galvanizing,Hot dip galvanized |

| Certification: | CE, ISO, SGS,BV,Mill Certificate | Standard: | ASTM,JIS,GB,DIN,EN |

| price terms | FOB,CRF,CIF,EXW, CPT | Payment Terms | T/T, L/C at sight,West Union |

| Grade | Q195—Grade B, SS330, SPC, S185 | ||

| Q215—Grade C,CS Type B, SS330, SPHC, | |||

| Q235—Grade D, SS400, S235JR, S235JO, S235J2, | |||

| Q345—SS500, ST52,S355JR | |||

| Delivery Detail | Standard has Stock; Normal About 3-5days; Custom-made 15-20days;According to order’s quantity. | ||

| Packing | standard export packing (inside:water proof paper,outside:fumigated wooden box) Hexagon Shape Bundle, Covered With Tarpaulin, Containers Or In Bulk |

||

hot-dip/cold galvanized steel pipe specification

| regulation | grid | OD

mm |

Wall thickness mm | Minimum wall | Welded pipe

( 6 m fixed length) |

Galvanized pipe

( 6 m fixed length) |

||

| Nominal inner diameter | inch | Thick mm | Meter weight kg | Root weight kg | Meter weight kg | Root weight kg | ||

| DN15 | 1/2 | 21.3 | 2.8 | 2.45 | 1.28 | 7.68 | 1.357 | 8.14 |

| DN20 | 3/4 | 26.9 | 2.8 | 2.45 | 1.66 | 9.96 | 1.76 | 10.56 |

| DN25 | 1 | 33.7 | 3.2 | 2.8 | 2.41 | 14.46 | 2.554 | 15.32 |

| DN32 | 1.25 | 42.4 | 3.5 | 3.06 | 3.36 | 20.16 | 3.56 | 21.36 |

| DN40 | 1.5 | 48.3 | 3.5 | 3.06 | 3.87 | 23.22 | 4.1 | 24.6 |

| DN50 | 2 | 60.3 | 3.8 | 3.325 | 5.29 | 31.74 | 5.607 | 33.64 |

| DN65 | 2.5 | 76.1 | 4 | 3.5 | 7.11 | 42.66 | 7.536 | 45.21 |

| DN80 | 3 | 88.9 | 4 | 8.38 | 50.28 | 8.88 | 53.28 | |

| DN100 | 4 | 114.3 | 4 | 10.88 | 65.28 | 11.53 | 69.18 | |

| DN125 | 5 | 140 | 4.5 | 15.04 | 90.24 | 15.942 | 98.65 | |

| DN150 | 6 | 168.3 | 4.5 | 18.18 | 109.08 | 19.27 | 115.62 | |

| DN200 | 8 | 219.1 | 6 (welded pipe) | 31.53 | 189.18 | |||

| DN200 | 8 | 219.1 | 6.5 hot-dip galvanizing | 36.12 | 216.72 | |||

GB / T 3091-2001 hot-dip galvanized pipe wall thickness deviation

| name

Weigh |

Chinese standard | Enterprise standard | Contrast conclusion | ||||||

| Low pressure fluid conveying welded steel pipe | Welded steel pipe | ||||||||

| GB/T3091-2001 | Q/YF01-2002 | ||||||||

| 1 | Steel pipe outer diameter | Steel pipe outer diameter,

outer diameter allowable deviation |

Better than Chinese standards | ||||||

| Outer diameter D/mm | Tube outer diameter deviation mm | Tube outer diameter

Deviation mm |

Outer diameter D | 8″ | ± 0.60mm | ||||

| D< 48.3 | ± 0.5mm | 5″-6″ | ± 0.50mm | ||||||

| 48.3<D <

168.3 |

± 1.0% | 4″ | ± 0.40mm | ||||||

| 168.3<D <

508 |

± 0.75% | +2.4 -0.8 | 3″-“ | ± 0.30mm | |||||

| D>508 | ± 1.0% | +3.0 -0.8 | 2″ or less | ± 0.20mm | |||||

| Wall thickness deviation | ± 12.5% | Wall thickness S | 1.8

5.75mm |

5% | |||||

| 2 | Usual length | Allowable deviation | length | Usual length | Allowable deviation | Better than Chinese standards | |||

| 4M-12M | +20 -0 | 2 inches or less | 5-0 | ||||||

| Double length: 5-10mn ® should be

left for each double in the usual length Margin |

+20 -0 | 2.5 inches – 4 inches | 5-0 | ||||||

| 5 inches or more | 15-0 | ||||||||

| Special length | 20-0 | ||||||||

Electro-Galvanization

Electro-galvanization, on the other hand, uses electrical current to deposit the zinc onto the surface of the steel. This process provides a more uniform coating and allows for better control over the thickness of the zinc layer. However, electro-galvanized pipes may not be as durable as hot-dip galvanized pipes, especially in harsh environmental conditions.

Advantages of Zinc Coated Galvanized Steel Pipes

- Corrosion Resistance: The zinc coating provides a barrier between the steel and the environment, preventing the corrosion that would otherwise occur when the steel is exposed to air and moisture.

- Long Lifespan: Because of their corrosion resistance, galvanized steel pipes can have a long service life, often up to 50 years in rural environments and 25 years in more severe urban and coastal environments.

- Low Maintenance: Once the galvanized steel pipes are installed, they require little maintenance because the zinc coating is very durable.

- Toughness: The galvanization process makes the pipes more durable and tough, which can be an advantage in applications where the pipes may be exposed to mechanical damage.

Applications of Zinc Coated Galvanized Steel Pipes

Galvanized steel pipes are used in a variety of applications, including:

- Plumbing: They are often used for carrying water in both residential and commercial buildings.

- Construction: Galvanized steel pipes are used in construction for a variety of purposes, including scaffolding, fencing, and as structural elements in buildings.

- Industrial Applications: In industries, these pipes are used for transporting substances like gases, combustible fluids, and corrosive chemicals.

- Agriculture: They are used in irrigation systems, greenhouses, and other agricultural structures.

In conclusion, zinc coated galvanized steel pipes are a popular choice for many applications due to their corrosion resistance, durability, and long lifespan. However, they must be used appropriately as they are not suitable for transporting certain types of materials, like highly acidic or alkaline substances, because these can corrode the zinc layer.

Standard: ASTM A53, BS1387-85, GB/T3091-08, DIN2440, JIS-G3444, EN10240, EN10255

Grade: Q195, Q215, Q235, Q345, S235JR, S275JR, STK400, STK500

API SPEC 5L — Specification for Line Pipe

ASTM A53/A53M — Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

ASTM A500 — Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes

BS 1387 — Specification for screwed and socketed steel tubes and tubulars and for plain end steel tubes suitable for welding or for screwing to BS 21 pipe threads

BS 1139 — Metal scaffolding. Specification for prefabricated mobile access and working towers

EN 39 — Loose steel tubes for tube and coupler scaffolds

EN 10255 — Non-alloy steel tubes suitable for welding and threading

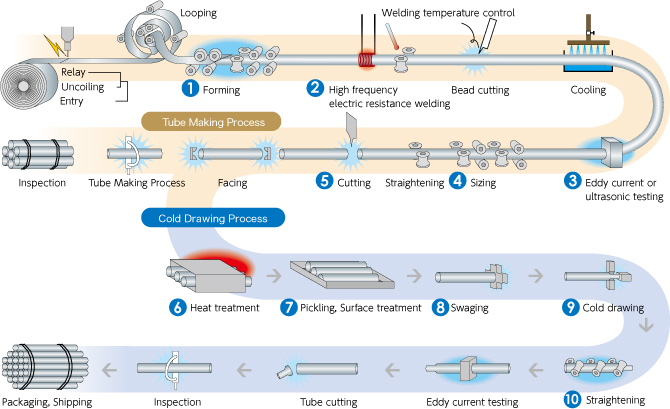

Welded pipe inspection – pickling – washing – coating solvent – aligning – drying – hot galvanizing – external blowing – internal blowing – water cooling – intermediate inspection – passivation – drying – typing – packaging – final inspection