Pre Insulated Pipe | Polyurethane Foam Insulation Pipe

A pre-insulated pipe with polyurethane foam insulation is a high-performance solution designed for the efficient transport of fluids, typically used in heating and cooling systems, or other industrial applications.

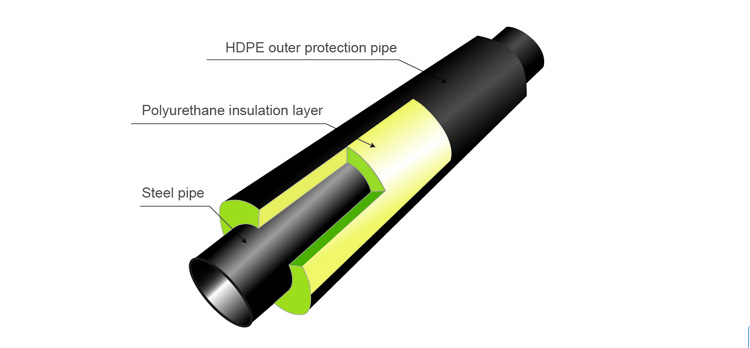

These pipes are characterized by their composite structure:

- Carrier Pipe: The innermost layer, or carrier pipe, is typically made of steel, copper, or plastic. This pipe is the conduit for the fluid being transported.

- Insulation Layer: The carrier pipe is surrounded by a layer of polyurethane foam insulation. This material is renowned for its excellent thermal insulation properties, keeping the transported fluid at a constant temperature and thereby minimizing energy loss. It’s a closed-cell foam, which means it’s also resistant to water. The foam’s density usually ranges between 30-45 kg/m3.

- Protective Jacket: The insulation layer is then enclosed within a protective outer jacket or casing. This can be made from a variety of materials, including steel, aluminum, or High-Density Polyethylene (HDPE), chosen for their mechanical strength and resistance to environmental conditions.

The advantages of using polyurethane foam insulation include high thermal insulation (high R-value), resistance to moisture, lightweight structure, compatibility with various carrier pipe materials, ease of fabricating joints and fittings, and consistent insulating properties over time.

These pre-insulated pipes are commonly used for transporting hot or cold liquids in HVAC systems, industrial processes, geothermal applications, and more. They are often installed underground or utilized in settings like refineries, power plants, and Liquefied Natural Gas (LNG) facilities.

The pipes are available in a wide range of sizes, with diameters from 1/2″ to over 60″. Smaller sizes are generally used in plumbing and HVAC applications, while larger sizes are used in industrial applications.

Pre-insulated pipes are usually prefabricated in straight lengths, which can then be joined in the field using a process called polyurethane foam welding.

Finally, these pipes and their insulation material must meet specific standards to ensure their performance and safety. The polyurethane insulation material should comply with ASTM C1440, and the pipe should meet the ASTM F754 standard.

In summary, pre-insulated pipes with polyurethane foam insulation offer a highly effective, durable, and energy-efficient solution for fluid transportation.

| Product Indexes | Reference Standard | Standard Requirement | Our product value |

| Outer protection pipe | |||

| Density (kg/m3 ) | CJ/T114-4.2.3.1 | ≥940 | 948.2 |

| Elongation at break (%) | CJ/T114-4.2.3.4 | ≥350 | 618 |

| Tensile yield strength (MPa) | CJ/T114-4.2.3.4 | ≥19 | 20.5 |

| Longitudinal shrinkage rate (%) | CJ/T114-4.2.3.5 | ≤3 | 1.23 |

| Long term Mechanical properties | CJ/T114-4.2.3.6 | >1500h(80℃,4.0 MPa)free from damage | Pass |

| The difference of the melt flow rate (g/10min) | CJ/T114-4.2.3.2 | ≤0.5 | 0.11 |

| Carbon Black Content % | CJ/T114-4.2.3.1 | 2.5±0.5 | 2.4 |

| Polyurethane insulation layer | |||

| Density (kg/m³) | CJ/T114-4.3.2 | ≥60 | 71.1 |

| Average pore size (mm) | CJ/T114-4.3.1 | ≤0.5 | qualified |

| Percentage of close area(%) | CJ/T114-4.3.1 | ≥88 | 94 |

| Compressive strength(MPa) | CJ/T114-4.3.3 | ≥0.3 | 0.58 |

| Water absorption(%) | CJ/T114-4.3.4 | Immersion in boiling water 90 minutes, bubble water absorption should be not more than 10% | ≤5.53 |

| Working steel pipe | |||

| Seamless steel pipe(≤DN150) | GB8163 | 20# | qualified |

| Spiral steel pipe(≥DN200) | GB/T9711 or SY/T5037 | Q235B | qualified |

PRODUCT FEATURES

| Product name | Thermal insulation direct buried pipe |

| Length | 5.8m-12m, or by customer’s requirements |

| Nominal diameter | DN25-1800 |

| Laid way | Buried |

| Application | Fluid Pipe, Natural gas, Gas, Oil, Hydraulic, chemical, drill, etc. |

| Production Standard | The national standard GB/T29047-2012, CJ/T114-2000, CJ/T155-2001 |

TECHNICAL INDICATORS

| Nominal diameter | OD ×Thickness(mm) | Outer protection tube diameter ×Wall thickness(mm) | Insulation thickness(mm) |

| 25 | 32×3 | 90×2.3 | 29 |

| 32 | 43×3 | 110×2.5 | 33 |

| 40 | 48×3 | 110×2.5 | 31 |

| 50 | 57×3 | 125×2.5 | 34 |

| 65 | 76×3.5 | 140×3 | 33 |

| 80 | 89×4 | 160×3.0 | 33 |

| 100 | 108×4 | 200×3.2 | 36 |

| 125 | 133×4.5 | 225×3.5 | 46 |

| 150 | 159×4.5 | 250×3.9 | 45.5 |

| 200 | 219×6 | 315×4.9 | 48 |

| 250 | 273×6 | 365×5.6 | 46 |

| 300 | 325×7 | 420×7 | 47.5 |

| 350 | 377×7 | 500×7.8 | 61.5 |

| 400 | 426×7 | 550×8.8 | 62 |

| 450 | 478×7 | 600×9.8 | 61 |

| 500 | 529×7 | 655×9.8 | 63 |

| 600 | 630×8 | 760×11 | 65 |

| 700 | 720×8 | 850×12 | 65 |

| 800 | 820×9 | 960×13 | 70 |

| 900 | 920×10 | 1054×14 | 67 |

| 1000 | 1020×12 | 1155×14 | 77 |

| 1200 | 1220×12 | 1380×15 | 80 |

| 1400 | 1420×14 | 1680×16 | 114 |

FAQ