Pre-Insulated Pipe and Fittings

What is The Pre-Insulated Pipe

Pre-insulated pipes, also known as bonded pipe systems, are piping systems that are designed for conveying hot or chilled fluids and gases, while minimizing heat loss or gain. They are widely used in district heating and cooling systems, oil and gas industries, and other applications where temperature control is crucial.

Structure

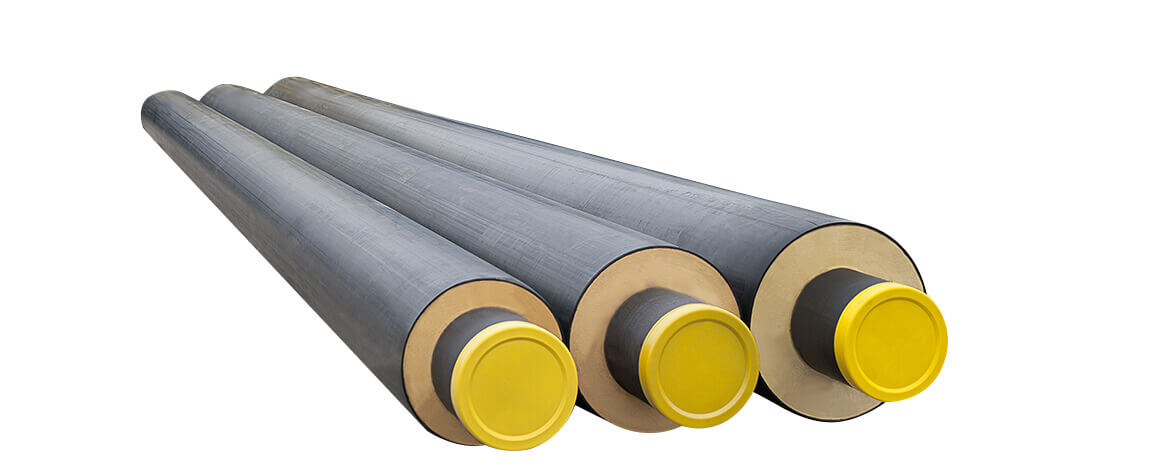

A typical pre-insulated pipe consists of three elements:

- Carrier Pipe: This is the innermost part of the pipe, and it directly carries the fluid or gas. It is usually made of steel, copper, or plastic depending on the application.

- Insulation Layer: Surrounding the carrier pipe is the insulation layer, designed to minimize heat transfer. Common materials for the insulation layer include polyurethane foam (PUF), mineral wool, or other high-performance insulating materials.

- Outer Jacket: The outermost layer of the pipe is the protective jacket, which shields the insulation and carrier pipe from mechanical damage and environmental conditions. It is usually made of high-density polyethylene (HDPE), PVC, or metal.

Benefits

Pre-insulated pipes offer several advantages over traditional pipe insulation methods:

- Efficiency: They significantly reduce heat loss (for hot fluid systems) or heat gain (for chilled fluid systems), leading to energy savings.

- Installation Time: Since the pipes are pre-insulated, the time and labor costs associated with onsite insulation are minimized.

- Durability: The outer jacket provides protection against mechanical damage, corrosion, and the elements, which can prolong the lifespan of the piping system.

- Space-saving: Pre-insulated pipes are more compact than traditionally insulated pipes, which can be a crucial advantage in spaces with limited room.

Applications

Pre-insulated pipes are used in a wide variety of situations:

- District heating and cooling: These systems distribute hot or chilled water from a central source to multiple buildings. Pre-insulated pipes keep the water at the desired temperature during transit.

- Oil and gas industry: Pre-insulated pipes help maintain the temperature of oil and gas in pipelines, which is especially vital in cold climates.

- Industrial processes: In many industries, certain fluids must be kept at specific temperatures to maintain the efficiency of the processes.

- Building services: In large-scale buildings like hospitals, universities, and commercial centers, pre-insulated pipes are often used to distribute hot or cold water, steam, and other utilities.

Despite their benefits, pre-insulated pipes may not be suitable for every situation due to their higher upfront cost compared to traditional piping systems. However, the long-term savings in energy and maintenance costs often offset the initial investment.

Abter steel Company Pre-Insulated Pipe

PDF DOWNLOADS: ABTER STEEL pre_insulated_pipes_catalogue2023

Our pre-insulated pipe solutions, under the brand ABTER STEEL, have found extensive application in heating and cooling systems. Designed to work harmoniously with various energy sources, these pre-insulated steel pipes boast enhanced durability.

We provide an all-encompassing solution to our clients, encompassing pre-insulated steel pipes, fittings, and assembly materials. With a rich inventory of pre-insulated steel and accessories, we ensure prompt delivery for small-scale projects. Besides, we offer pre-insulated solutions for medium pipes such as PE, stainless, and other tailor-made options.

We work in close collaboration with our clients, planning our projects with reputable logistics partners and delivering our products on a global scale. We also facilitate the provision of necessary export documentation.

Our manufacturing facility is compliant with the environmental standards of 14001:1998 and holds the Euro Heat & Power certification. We provide VCA* certified installation services (including adjustment, welding, and post-insulation), and assembly guidelines specifically for the utility sector. Our pipes are available in the Duo format, which includes two pipes within a single casing.

The external surface of our steel pipes undergoes shot peening for enhanced adherence of the rigid polyurethane foam (PUR). The steel main pipe ends are beveled in preparation for welding. The inner surface of the polyethylene pipe undergoes corona treatment to improve the adhesion of the PUR.

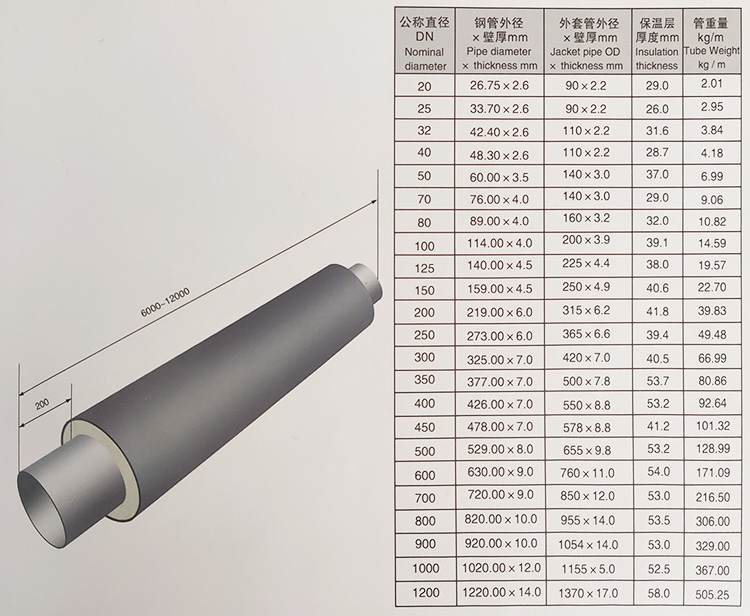

Technical Specifications

- Medium pipe: The ABTER STEEL steel P235GH is manufactured in accordance with PN-EN-10217-1 standards. We offer both welded and seamless options.

- Temperature range: Our pipes can handle temperatures from 10°C to 149°C.

- Casing pipe: We use HDPE, with an optional diffusion barrier.

- Insulation material: We use 100% CKF-free blown PUR-foam.

- Thermal conductivity: The thermal conductivity of our pipes ranges from 0.025 to 0.029 W/mK.

- Maximum operating temperature: Our pipes can withstand up to 149 ºC.

- Diameter range: We offer diameters ranging from DN20 to DN1000.

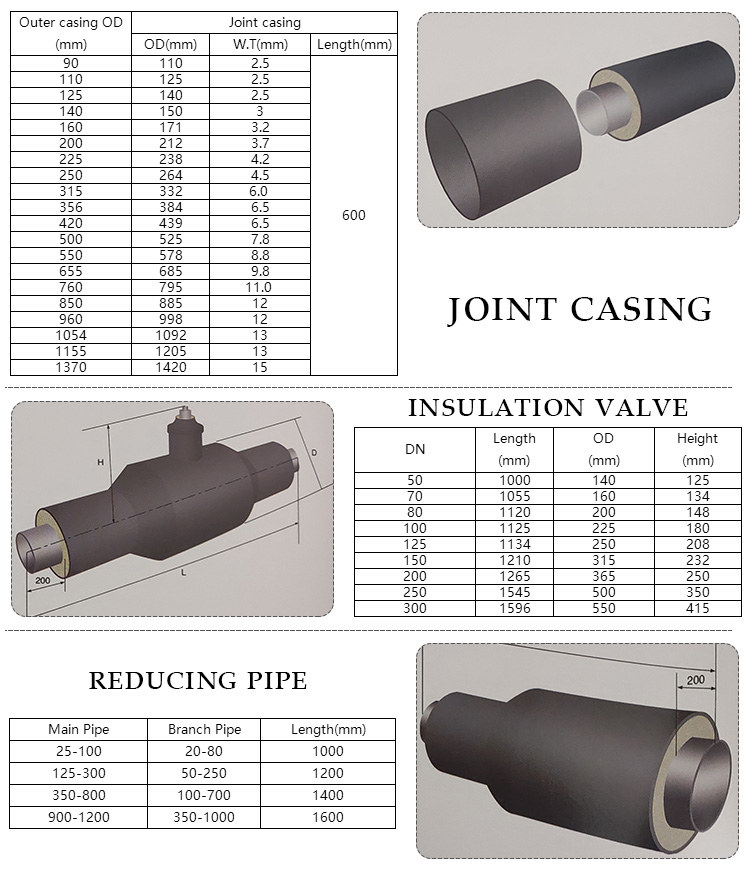

- Joint connections: Our THERMA-TUBE PEH-shrinking joints feature a double closure, and we use liquid PUR foam or PUR shells for insulation.

- Leak detection system: All our pre-insulated pipes and fittings are equipped with Nordic alarm wires.

- Ground coverage: Our pipes are designed considering a ground cover of 80 centimeters.

.

Applications-Pre-insulated pipe system are used by the chemical,

pharmaceutical, petro-chemical and food industries for the transport of:

-

- District heating networks

- District cooling networks

- Chilled water, Drinking water, Waste water, Cooling water, Hot water

- Steam & condensate lines

- Process fluids

- Refrigerants

- Chemicals

- Oil

A pre-insulated pipe normally consists of three parts

Part 1: Carrier pipe (Inside): Stainless steel or Carbon steel

Part 2: Insulating layer (Medium): Polyurethane foam (PUR Form) (High

insulation qualities compared to mass and volume)

Part 3: Protective jacket (Outside casing): Plastic or steel (Polyethylene

(PEH), High Density Polyethylene (HDPE), Galvanized, Aluminum etc)

Pos: The choice of carrier pipe, foam type and foam thickness, as well

as the material for the jacket, is made by the customer, who can also choose to

supply carrier pipes for the project.

Advantages: impact-proof, watertight, resistant to salt and chemicals,hygienic and non-corrosive

| Materials | ||

| Item | Material | Notes |

| Service pipe/Carrier pipe | Steel Pipe | API 5L PSL-1: GR.B X42, X46, X52, X60, X70 API 5L PLS-2: ISO3183-L245, L290, L320, L360, L415, L485 |

| Insulation | Polyurethane foam (PUR) Nominal Density of 60¹+15-15 kg/m³ |

Compressive Strength: ≥ 0.300 Mpa |

| Thermal Conductivity: ≤ 0.029 W/m·K@50ºC | ||

| Closed Cell Content: ≥90% | ||

| Water Absorption: <5% | ||

| Insulation Jacket | High-density polyethylene (HDPE) | As technical parameter |

| Description | polyurethane thermal insulation steel pipe |

| Wall thickness | 0.5mm-16mm |

| Length | 1m-12m or customized |

| Outer Diameter | 0.405-80 inch or 10.3mm – 2032mm |

| Insulation | PUR Foam |

| Operating temperature | Up to 140ºC |

| Standard & Grades | API 5L PSL1/ PSL2, ASTM A53,ASTM A252,GB/T9711.1,GB/T3091,SY/T 5037-2012,DIN1626,EN10219,EN10217 |

| Ends | 30~35° |

| Quality control | 100% X-Ray inspection/ 100%X 100% Hydraulic Pressure test/ 100% 100% Ultrasonic inspection / 100% |

| Lining | Epoxy , cement motar, and according to customers requirement |

| Operating pressure | <1.6Mpa (Equivalent to PN 25? 25bar to be confirmed) |

| Laid way | Buried, overhead, trench |

| Insulation material | Fluoride-Free water foamed rigid polyurethane foam material (foam density: 60kg/m3-80kg/m³) |

| Inner surface tension of the high density polyethylene pipe |

≥50dy/cm |

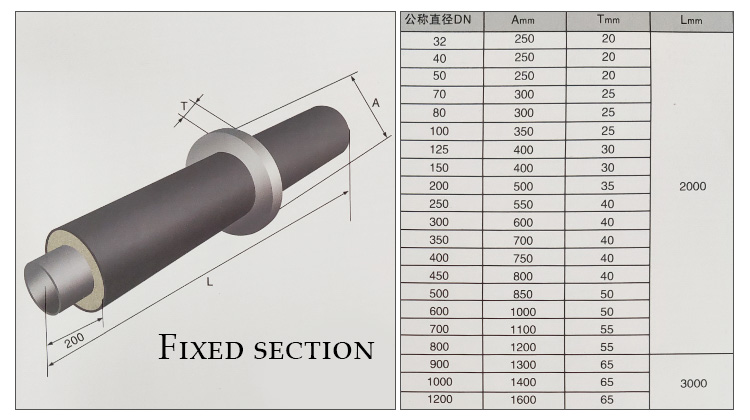

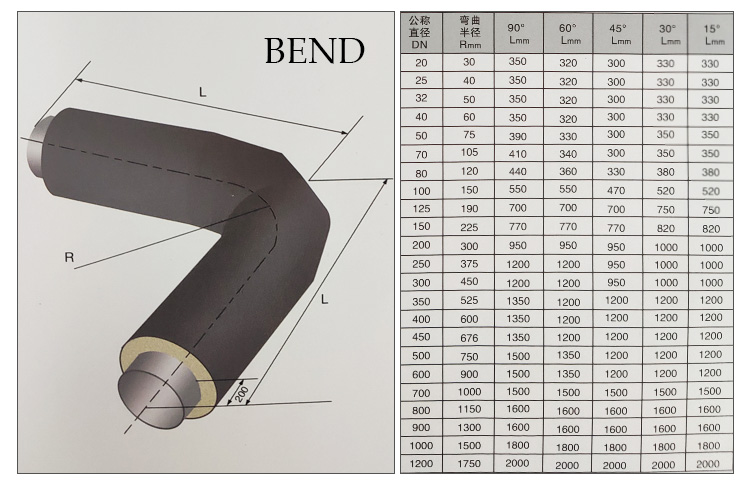

Pre-insulated pipes and accessories