Thermal Insulation Pipe Systems | Polyurethane Foam Insulation Pipe | Overhead Insulation Pipe

Pre-Insulated Steel Pipe Polyurethane Foam Insulation Pipe Overhead insulation pipe

Why use Pre-insulated Pipes?

The Benefits of Using Pre-insulated Pipes

Pre-insulated pipes offer a host of advantages that make them an attractive option for various applications. Here are some key reasons why they are commonly used:

- Thermal Efficiency: The insulating layer of pre-insulated pipes preserves the temperature of the fluid being transported. This reduces the need for additional heating or cooling along the pipeline, thereby saving energy.

- Durability and Longevity: The protective cladding safeguards the insulation layer, protecting it from environmental damage, moisture, and mechanical stress. This protection helps to extend the lifespan of the pipe system and reduce maintenance requirements, leading to long-term cost savings.

- Safety: The external cladding also provides an additional layer of safety, protecting the pipeline from potential damage and reducing the risk of leaks that could harm the environment or pose safety risks.

- Versatility: Pre-insulated pipes are suitable for a wide range of applications, including district heating and cooling systems, water and wastewater transmission, and oil and gas pipelines.

- Ease of Installation: Pre-insulated pipes typically come as a single unit consisting of the pipe, insulation, and cladding, which makes them easier and quicker to install than traditional pipe-insulation systems.

- Environmental Impact: By maintaining the temperature of the transported fluids and reducing the need for additional heating or cooling, pre-insulated pipes help to lower greenhouse gas emissions.

In conclusion, the use of pre-insulated pipes can lead to significant benefits in terms of energy efficiency, cost savings, safety, and environmental sustainability.

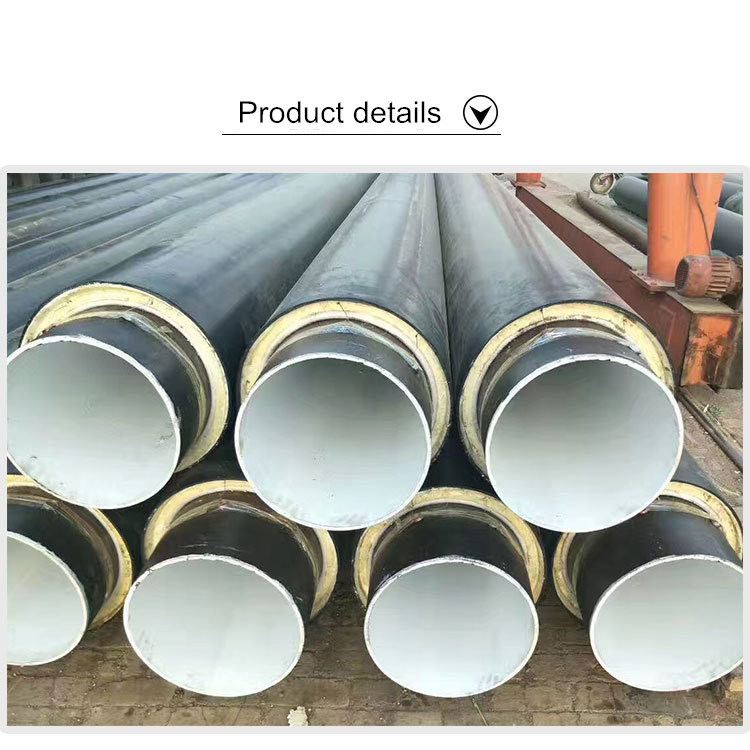

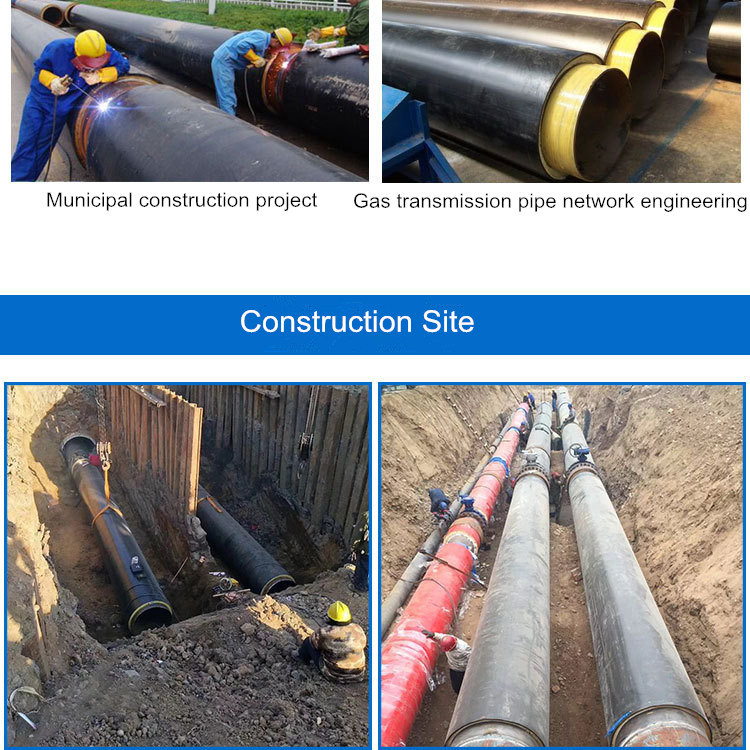

Pre-insulated pipes serve numerous applications in diverse fields such as district heating and cooling, water and wastewater transmission, as well as oil and gas pipelines. The construction of these pipes includes a central pipe, responsible for the flow of the transported fluid, surrounded by an insulating layer, all protected by an external layer or cladding. The insulation’s role is to preserve the fluid’s temperature, while the cladding safeguards the insulation and aids in maintaining the pipe system’s integrity.

Typically, pre-insulated pipes featuring metal cladding are made from materials such as carbon steel, stainless steel, or aluminum. The method of roll bonding is used to apply the metal cladding over the insulation. This process involves bonding the metal and insulation layers together under heat and pressure. The metal cladding offers protection to the insulation layer against mechanical damages, moisture, and various environmental factors, thereby enhancing the pipe system’s lifespan.

The use of pre-insulated pipes with metal cladding is prevalent in various industries such as power generation, oil and gas, and district heating and cooling. These pipes are especially beneficial in scenarios where they are subjected to extreme temperatures, mechanical stress, or other severe conditions. The metal cladding adds an extra protective layer for the insulation, which contributes to the pipe system’s long-term reliability and performance.

What codes and standards do we follow at abtersteel?

abtersteelmanufactures its product range for district cooling strictly in compliance with EN17415-1, EN17415-2, EN17415-3, EN489 and other relevant standards, which will ensure a technical lifetime of minimum 50 years when designed and installed correctly.

Specification1.The pre-insulated steel pipe coated with high density polyurethane foam can resistant the temperature up to 140°c.

2.With the corrosion resistant hdpe jacket pipe can make the pipe directly buried underground without trench.

3.Different size pipe and pipe fittings can service for different heating and cooling project.

4.The polyurethane foam thickness can be designed from 26.5-83mm or more.

Type test of welded joint include the following tests:

- Polyurethane (PUR) foam thermal stability

- Water tightness

- Stress crack resistance

- Bending test on welded plug

- Melt mass-flow rate of welded plug

Additional to this type test we are testing our weld joints according to:

- Soil stress test (Sand Box test)

- Water tightness test (after soil stress test)

- Polyurethane thermal stability

- Bending test on welded plug

- Melt mass-flow rate of welded plug

Type test shrinkable sealed joint include the following test:

- Polyurethane (PUR) foam thermal stability

- Soil stress test (Sand Box test)

- Water tightness (after soil stress test)

- Bending test on welded plug

- Melt mass-flow rate of welded plug

PIPE DATAS

| DN | Steel pipe(mm) | HDPE pipe(mm) | Thickness of insulation layer | ||

| diameter | thickness | diameter | thickness | (mm) | |

| 25 | 32 | 3 | 90 | 2.5 | 26.5 |

| 40 | 45 | 3.5 | 110 | 2.5 | 30 |

| 50 | 57 | 3.5 | 120 | 3 | 28.5 |

| 70 | 76 | 4 | 140 | 3 | 29 |

| 80 | 89 | 4 | 150 | 3 | 27.5 |

| 100 | 108 | 4.5 | 180 | 3 | 33 |

| 125 | 133 | 4.5 | 225 | 3.5 | 42.5 |

| 150 | 159 | 5 | 250 | 3.9 | 41.6 |

| 200 | 219 | 6 | 315 | 4.9 | 43.1 |

| 250 | 273 | 6 | 365 | 5.6 | 40.4 |

| 300 | 325 | 7 | 420 | 7 | 40.5 |

| 350 | 377 | 7 | 500 | 7.8 | 53.7 |

| 400 | 426 | 7 | 560 | 8.8 | 58.2 |

| 450 | 478 | 8 | 600 | 8.8 | 52.2 |

| 500 | 529 | 8 | 655 | 9.8 | 53.2 |

| 600 | 630 | 8 | 760 | 11.5 | 53.5 |

| 700 | 720 | 8 | 850 | 12 | 53 |

| 800 | 820 | 10 | 960 | 14 | 56 |

| 900 | 920 | 10 | 1055 | 14 | 53.5 |

| 1000 | 1020 | 10 | 1155 | 14 | 53.5 |

| 1100 | 1120 | 12 | 1256 | 14 | 54 |

| 1200 | 1220 | 12 | 1370 | 16 | 59 |

| 1200 | 1220 | 14 | 1370 | 16 | 59 |

| 1400 | 1420 | 14 | 1580 | 16 | 64 |

| 1400 | 1420 | 16 | 1600 | 18 | 72 |

INSULATED INFOS

| Description | polyurethane thermal insulation steel pipe |

| Wall Tickess | 0.5mm-16mm |

| Length | 1m-12m ,or by customer’s requirements |

| Production Standard | API 5L PSL1/ PSL2,ASTM A53,ASTM A252,GB/T9711.1,GB/T3091,SY/T 5037-2012,DIN1626,EN10219,EN10217 |

| End | 30~35° Beveled end |

| Quality Control | 100% X-Ray inspection 100%Hydraulic Pressure test 100% Ultrasonic inspection |

| Internal lining | Epoxy , cement motar, and according to customers requirement |

| Operating pressure | <1.6Mpa |

| Laid way | Buried, overhead, trench |

| Grade of the steel pipe

and pipe fitting |

20#/Q235 Seamless steel pipe and spiral steel pipe (GB and oil standard) |

| Insulation material | Fluoride-Free water foamed rigid polyurethane foam material

(foam density: 60kg/m3-80kg/m3 |

| Inner surface tension of the

high density polyethylene pipe |

≥50dy/cm |

| Product name | district heating polyurthane foam insulation flexible hot water pipe |

| thermal insulation pipe | |

| polyurethane pipe insulation | |

| waterproof pipe | |

| Composition | |

| Usage | 1.urban centralized heat supply |

| 2.warm room | |

| 3.coal mine | |

| 4.petroleum | |

| 5.chemical and other anti-corrosion insulation field | |

| Medium teperature | 50°C-120°C,Max:140 °C |

| Working pressure | <2.5Mpa |

| Laying method | 1.direct bury |

| 2.built on stilts | |

| 3.trench | |

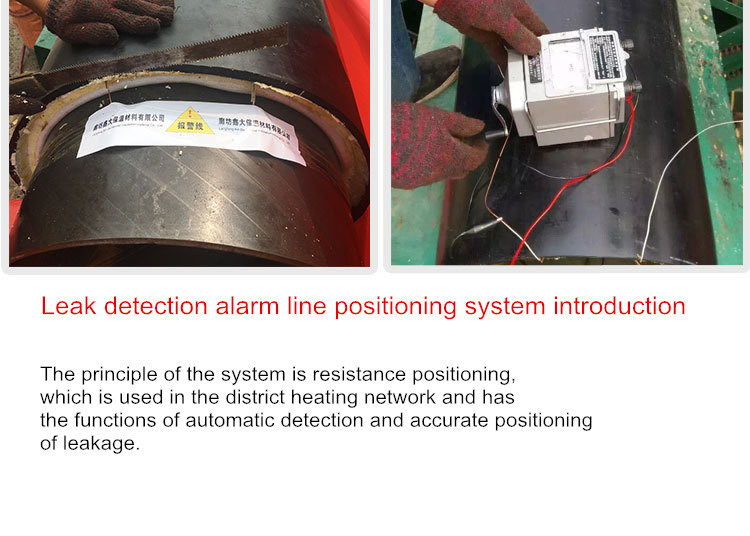

| Technology | 1.Advanced Corona treatment |

| 2.Impeller blasting | |

| 3. Leakage alarm line | |

| Standards | CJ/T114-2000, CJ/T155-2001, EN253:2003 |

| GB/T9711.1-1997, GB/T8163-1999 | |

| Advantages | 1.good insulation properties ,low heat loss (the 25% of traditional pipes), |

| 2.energy saving | |

| 3.waterproof and corrosion resisdence | |

| 4.no trench,be directly buried in ground or water | |

How do pre-insulated pipes compare in cost to traditional pipe-insulation systems?

Comparing the Costs: Pre-Insulated Pipes vs. Traditional Pipe-Insulation SystemsWhen comparing the costs of pre-insulated pipes to traditional pipe-insulation systems, it’s critical to consider both the upfront costs and the long-term operational costs.

Upfront Costs

From an initial investment perspective, pre-insulated pipes can be more expensive than traditional pipe-insulation systems. This is due to the advanced manufacturing process and the integrated design, which includes the pipe, insulation, and protective cladding all in one unit.

Long-Term Operational Costs

While the upfront costs for pre-insulated pipes might be higher, the long-term operational costs often prove to be lower. Here’s why:

- Energy Efficiency: Pre-insulated pipes are highly efficient at maintaining the temperature of the transported fluids, reducing the need for additional energy for heating or cooling. This leads to significant energy savings over time.

- Durability: The protective cladding of pre-insulated pipes protects the insulation from damage, extending the lifespan of the pipe system and reducing the need for maintenance or replacement.

- Ease of Installation: Because pre-insulated pipes come as an integrated unit, they can be quicker and easier to install than traditional systems, cutting down on labor costs.

Overall Cost Comparison

In short, while pre-insulated pipes may have a higher initial cost, their energy efficiency, durability, and ease of installation can lead to significant savings in the long run. Therefore, when comparing the costs of pre-insulated pipes and traditional pipe-insulation systems, it’s important to consider the total lifecycle costs, not just the upfront investment.