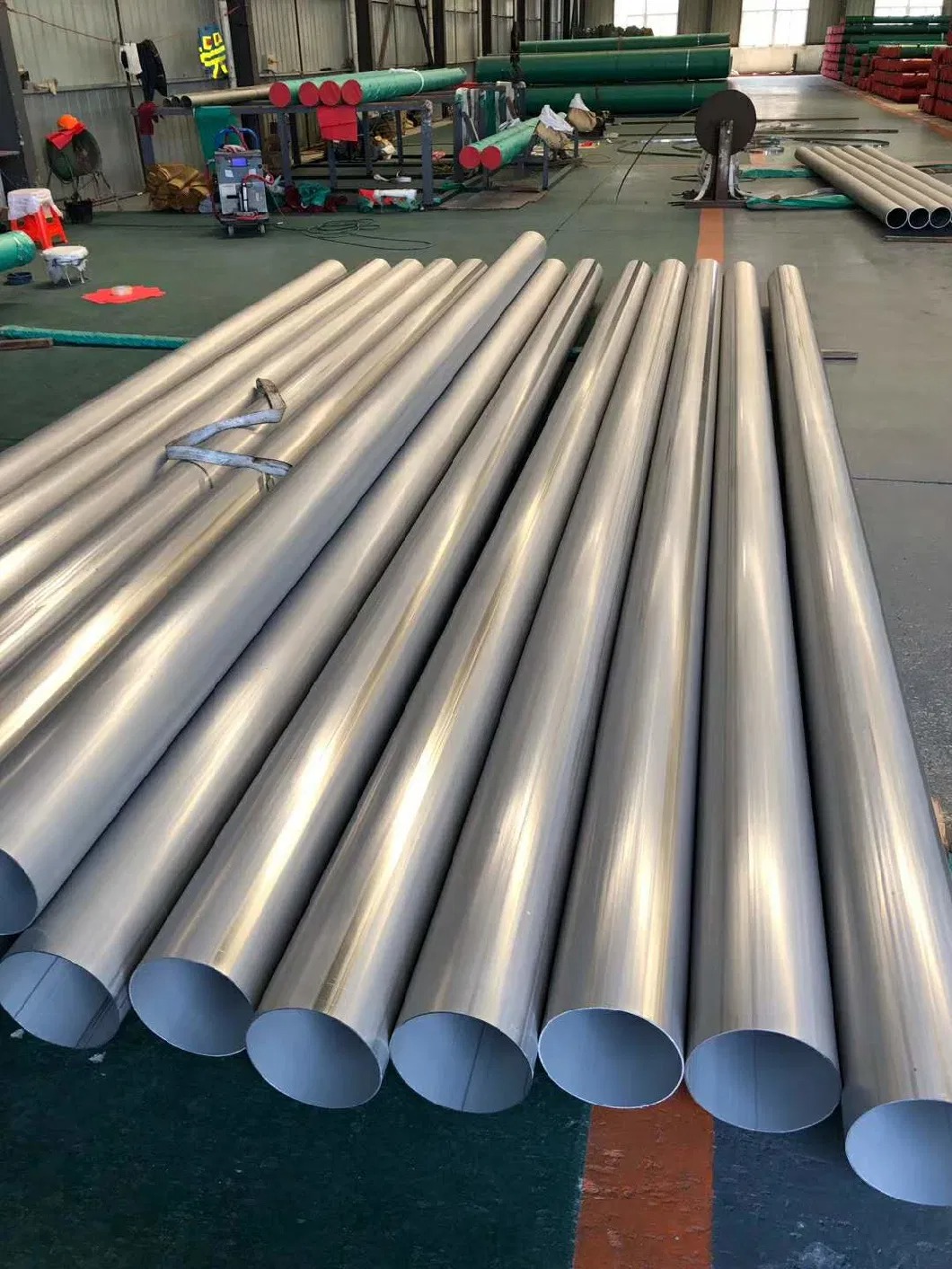

ASME SA789 and ASME SA790 Duplex Stainless Steel Pipe

ASME SA789 and ASME SA790 are two standards that specify requirements for duplex (austenitic-ferritic) stainless steel tubing and pipe. These standards are published by the American Society of Mechanical Engineers (ASME) and are widely used in the construction of pressure vessels, heat exchangers, and piping systems in various industries.

ASME SA789:

Standard Specification: ASME SA789 / SA789M – Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service.

Scope: This specification covers standard requirements for grades of nominal wall thickness, stainless steel tubing for services requiring general corrosion resistance, with particular emphasis on resistance to stress corrosion cracking. These steels are susceptible to embrittlement if used for prolonged periods at elevated temperatures.

Materials: The duplex stainless steels covered by this specification are listed in Table 1 and Table 2 of the standard, and the specific UNS numbers include S31803, S32205, S32750, S32760, among others.

Applications: The tubing specified by ASME SA789 is commonly used in the heat exchanger systems, chemical processing industry, oil and gas extraction, and refining systems.

ASME SA790:

Standard Specification: ASME SA790 / SA790M – Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe.

Scope: This specification covers seamless and straight-seam welded ferritic/austenitic steel pipe intended for general corrosive service, with particular emphasis on resistance to stress corrosion cracking. This pipe is intended for high-temperature and general corrosive service.

Materials: The duplex stainless steels covered by this specification are the same as those listed in SA789, with the addition of other grades as specified in the standard.

Applications: The pipes specified by ASME SA790 are used in a variety of applications including process piping systems in the chemical, petrochemical, paper, textile, and environmental technology industries, as well as in pipelines and heat exchanger units.

Common Features of Duplex Stainless Steel:

- High strength: Duplex stainless steels have higher strength than austenitic stainless steels and can be used in thinner sections to reduce weight.

- Good weldability: Despite their high strength, duplex stainless steels generally have good weldability.

- Corrosion resistance: Duplex stainless steels have a high resistance to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking.

- Cost-effectiveness: Due to their high strength and corrosion resistance, duplex stainless steels can lead to cost savings in the long term.

When selecting duplex stainless steel pipes or tubes, it is crucial to consider the specific environment and chemical exposures they will face to ensure the selected grade provides adequate corrosion resistance and mechanical properties for the intended application. Always refer to the full ASME standards for comprehensive requirements and consult with a materials engineer or a professional in the field for specific applications.

The ASME SA789 and ASME SA790 standards cover the requirements for duplex stainless steel pipes and tubes, including the chemical composition and mechanical properties. Below are the typical ranges for the chemical composition and mechanical properties for duplex stainless steel according to these specifications. Keep in mind that these can vary slightly based on the specific duplex grade.

Chemical Composition:

The chemical composition for duplex stainless steel according to ASME SA789 and ASME SA790 for the common grades (such as S31803, S32205, which are often referred to as Alloy 2205) is typically as follows:

- Chromium (Cr): 21.0% to 23.0%

- Nickel (Ni): 4.5% to 6.5%

- Molybdenum (Mo): 2.5% to 3.5%

- Manganese (Mn): ≤2.00%

- Silicon (Si): ≤1.00%

- Nitrogen (N): 0.14% to 0.20%

- Carbon (C): ≤0.030%

- Phosphorus (P): ≤0.030%

- Sulfur (S): ≤0.020%

- Iron (Fe): Balance

Mechanical Properties:

The mechanical properties for duplex stainless steel according to ASME SA789 and ASME SA790 for the common grades are typically as follows:

- Tensile Strength: Minimum 620 MPa

- Yield Strength (0.2% Offset): Minimum 450 MPa

- Elongation: Minimum 25% in 50mm

- Hardness: Maximum 290 HBW (Brinell) or 30 HRC (Rockwell C)

- .

Super Duplex Stainless Steel:

For super duplex stainless steel grades such as UNS S32750 and UNS S32760, the chemical composition and mechanical properties will be somewhat different, reflecting their enhanced performance characteristics.

Chemical Composition (UNS S32750):

- Chromium (Cr): 24.0% to 26.0%

- Nickel (Ni): 6.0% to 8.0%

- Molybdenum (Mo): 3.0% to 5.0%

- Manganese (Mn): ≤1.20%

- Silicon (Si): ≤0.80%

- Nitrogen (N): 0.24% to 0.32%

- Carbon (C): ≤0.030%

- Phosphorus (P): ≤0.035%

- Sulfur (S): ≤0.020%

- Copper (Cu): 0.5% to 1.0%

- Iron (Fe): Balance

Mechanical Properties (UNS S32750):

- Tensile Strength: 795 MPa minimum

- Yield Strength (0.2% Offset): 550 MPa minimum

- Elongation: 15% minimum in 50mm

- Hardness: Maximum 310 HBW (Brinell) or 32 HRC (Rockwell C)

It’s important to consult the actual standard or the material test certificates for the specific batch of material you are using, as these provide the exact values that the material has been tested to meet. The specifications for other grades of duplex and super duplex stainless steel will vary, and it’s crucial to ensure that the selected material meets the requirements of the application in terms of both chemical composition and mechanical properties.

| Chemical Composition | |||||||||

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | N |

| max | max | max | max | max | |||||

| UNS S32750 | 0.03 | 0.8 | 1.2 | 0.03 | 0.015 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | 0.24-0.32 |

| UNS S31803 | 0.03 | 1 | 2 | 0.02 | 0.02 | 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | 0.08-0.20 |

| Physical Properties | |||||||||

| Grade | Y.S.MPa min | T.S.Mpa min | Elongation % | Hardness HRC | / | ||||

| UNS S32750 | 550 | 800 | 15 | 20 | / | ||||

| UNS S31803 | 450 | 620 | 25 | 20 | / | ||||

2 comments

pools

2023年12月22日 at pm8:54

What is SA789 material?

Ronsun2023

2023年12月22日 at pm8:57

ASTM A789 / A 789M, ASME SA789 S31803 Duplex Stainless Tubing is for Boilers, Superheaters and Heat Exchangers. ASTM A789 /A789M Covers Grades of nominal wall thickness, stainless steel tubing for services requiring general corrosion resistance, with particular emphasis on resistance to stress corrosion cracking.