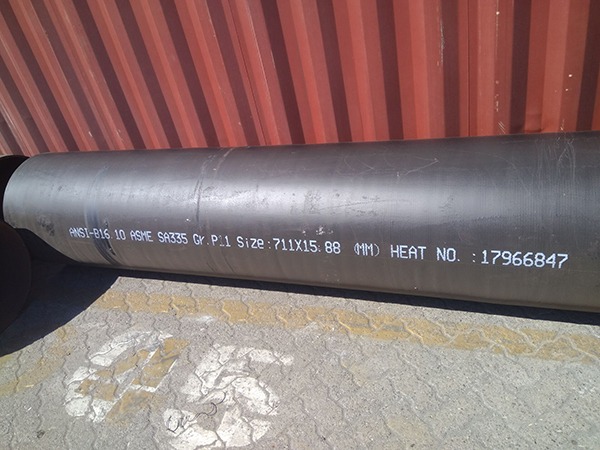

ASTM/ASME A335 / SA335 Alloy steel pipe

ASTM A335 and ASME SA335 are standards for seamless ferritic alloy steel pipes intended for high-temperature service. These pipes are commonly used in the power generation, petrochemical, and oil and gas industries due to their excellent mechanical properties, resistance to corrosion, and the ability to withstand high temperatures and pressures.

a335 alloy steel P11, P12, P22,P9, pipe this specification is suitable for high temperature 610ºC, it is used as main steam pipe for power plant, super heater and reheater for heat resistant and good processing performance.

ASTM A335 refers to the American Society for Testing and Materials (ASTM) standard for seamless ferritic alloy steel pipes, while ASME SA335 refers to the American Society of Mechanical Engineers (ASME) standard for the same type of pipes.

The A335/SA335 standard covers several grades of alloy steel pipes, each with unique chemical compositions and mechanical properties. The most common grades include:

- P1: This grade has a lower chromium and molybdenum content, which makes it more economical but with lower corrosion resistance and high-temperature strength compared to other grades.

- P5: This grade contains 5% chromium and is used in applications that require increased strength and resistance to high temperatures, such as power plants and petrochemical facilities.

- P9: This grade has a higher chromium and molybdenum content, providing better high-temperature strength and corrosion resistance. It is commonly used in applications like steam pipelines and heat exchangers.

- P11: This grade is widely used in the power generation and petrochemical industries due to its good balance between cost, strength, and corrosion resistance.

- P22: This grade is known for its excellent creep resistance and high-temperature strength, making it suitable for high-stress applications like steam pipelines and boilers.

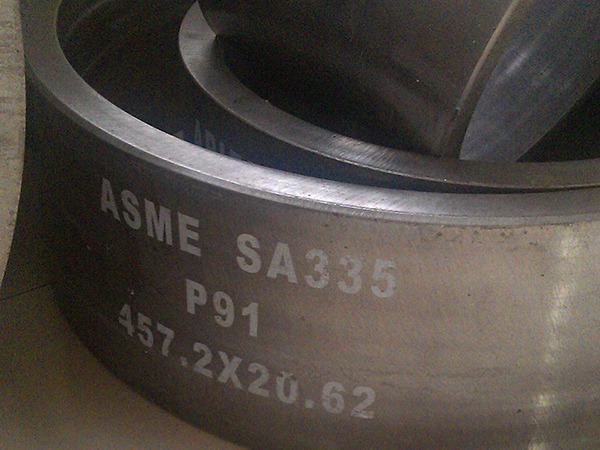

- P91: This grade is a high-performance alloy steel with a high chromium and molybdenum content, offering superior strength, corrosion resistance, and creep resistance. It is commonly used in power plants, particularly in high-pressure and high-temperature applications.

When selecting an A335/SA335 alloy steel pipe, consider the specific application, required mechanical properties, and temperature and pressure requirements to ensure you choose the appropriate grade and specifications for your project. Always refer to the relevant standards and consult with a professional engineer when necessary.

ASTM A335 Chemical Composition:

| ASTM A335 Steel Grade | C, % | Mn, % | P, % | S, % | Si, % | Cr, % | Mo, % |

|---|---|---|---|---|---|---|---|

| ASTM A335 P1 | 0.05-0.15 | 0.30-0.60 | 0.025 max | 0.025 max | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 |

| ASTM A335 P2 | 0.10-0.20 | 0.30-0.61 | 0.025 max | 0.025 max | 0.10-0.30 | 0.50-0.81 | 0.44-0.65 |

| ASTM A335 P5 | 0.15 max | 0.30-0.60 | 0.025 max | 0.025 max | 0.50 max | 4.00-6.00 | 0.45-0.65 |

| ASTM A335 P9 | 0.15 max | 0.30-0.60 | 0.025 max | 0.025 max | 0.25-1.00 | 8.0-10.0 | 0.90-1.10 |

| ASTM A335 P11 | 0.05-0.15 | 0.30-0.60 | 0.025 max | 0.025 max | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 |

| ASTM A335 P12 | 0.05-0.15 | 0.30-0.61 | 0.025 max | 0.025 max | 0.50 max | 0.80-1.25 | 0.44-0.65 |

| ASTM A335 P22 | 0.05-0.15 | 0.30-0.60 | 0.025 max | 0.025 max | 0.50 max | 1.90-2.60 | 0.87-1.13 |

| Steel Grade | C, % | Mn, % | P, % | S, % | Si, % | Cr, % | Mo, % | V, % | Nb, % | B,% | N, % | Al, % | Ni,% | W, % |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ASTM A335 P23 | 0.04-0.10 | 0.1-0.6 | 0.03 max | 0.01 max | 0.5 max | 1.9-2.6 | 0.05-0.30 | 0.20-0.30 | 0.02-0.08 | 0.0005-0.006 | 0.03 max | 0.03 max | – | 1.45-1.75 |

| ASTM A335 P91 | 0.08-0.12 | 0.3-0.6 | 0.02 max | 0.01 max | 0.2-0.5 | 8.0-9.5 | 0.85-1.05 | 0.18-0.25 | 0.06-0.10 | – | 0.03-0.07 | 0.04 max | 0.4 max | – |

| ASTM A335 P92 | 0.07-0.13 | 0.3-0.6 | 0.02 max | 0.01 max | 0.5 max | 8.5-9.5 | 0.3-0.6 | 0.15-0.25 | 0.04-0.09 | 0.001-0.006 | 0.03-0.07 | 0.04 max | 0.4 max | 1.5-2.0 |

ASTM A335 Mechanical Property:

| Steel Grade | Tensile Strength, MPa | Yield Strength, MPa | Elongation, % | Hardness, HB |

|---|---|---|---|---|

| ASTM A335 P1 | 415 min | 205 min | 30 min | |

| ASTM A335 P2 | 380 min | 205 min | 30 min | |

| ASTM A335 P5 | 415 min | 205 min | 30 min | |

| ASTM A335 P9 | 415 min | 205 min | 30 min | |

| ASTM A335 P11 | 415 min | 205 min | 30 min | |

| ASTM A335 P12 | 415 min | 220 min | 30 min | |

| ASTM A335 P22 | 415 min | 205 min | 30 min | |

| ASTM A335 P23 | 510 min | 400 min | 20 min | |

| ASTM A335 P91 | 585 min | 415 min | 20 min | 250 max |

| ASTM A335 P92 | 620 min | 440 min | 20 min | 250 max |

ASTM A335 Equivalent steel grade:

| Steel grade | EN | ASTM | ASME | GOST | NBR |

|---|---|---|---|---|---|

| ASTM A335 | EN10216-2 | ASTM A213 | ASME SA213 | 550-75 | 5603 |

TESTING REQUIREMENTS

- Transverse/longitudinal: tension and flattening, hardness, bend tests- for material that has been heat-treated in batch furnaces, these tests shall be made on the 5% of the pipes from each heat lot number. For smaller lots, one pipe at a minimum has to be tested

- ASTM A335 Gr. P91 shall have a hardness of 250 HB / 265 HV (25 HRC)

- Hydro testing: shall be applied to every length of pipe

- The non-destructive electric test is optional

TOLERANCES

DIAMETER

| A335 Pipe | Over | Under | ||

| NPS [DN] | in. | mm | in. | mm |

| 1/8 to 1 1/2 / DN 6 to 40 | 1/64 (0.015) | 0.4 | 1/64 (0.015) | 0.4 |

| Over 1 1/2 to 4 / DN 40 to 100 | 1/32 (0.031) | 0.79 | 1/32 (0.031) | 0.79 |

| Over 4 to 8 / DN 100 to 200 | 1/16 (0.062) | 1.59 | 1/32 (0.031) | 0.79 |

| Over 8 to 12 / DN 200 to 300 | 3/32 (0.093) | 2.38 | 1/32 (0.031) | 0.79 |

| Over 12 / > DN 300 | +/- 1% of the specified outside diameter |

WALL THICKNESS

The tolerances in WT, in %, from specified are:

- 1/8 to 2 1/2 [6 to 65] incl., all t/D ratios: over 20%, under 12.5%

- Above 2 1/2 [65], t/D < or = 5%: over 22.5%, under 12.5%

- Above 2 1/2 [65], t/D > 5%: over 15%, under 12.5%

t = Specified Wall Thickness; D = Specified Outside Diameter)

ALLOY PIPE CROSS REFERENCE TABLE ASTM vs. EN GRADES

| Chrome Moly Pipes: Werkstoff vs EN vs ASTM | ||

|---|---|---|

| Werkstoff /DIN | EN | ASTM |

| 1.5415 | 16Mo3 | A335 Grade P1 |

| 1.7335 | 13CrMo4-5 | A335 Grade P11, P12 |

| 1.7380 | 10CrMo9-10 | A335 Grade P22 |

| 1.7362 | X11CrMo5 | A335 Grade P5 |

| A335 Grade P9 | ||

| 1.4903 | X10CrMoVNb9-1 | A335 Grade P91 |

A335 steel pipe Heat Treatment:

A335 pipes shall be reheated and furnished in the full-annealed, isothermal annealed, or normalized and tempered condition. If furnished in the normalized and tempered condition, the minimum tempering temperature for Grades P5, P5b, P9, P21, and P22 shall be1250°F [675°C], the minimum tempering temperature for Grades P1, P2, P11, P12, and P 15 shall be 1200°F [650°C].

Pipe of Grades P1, P2, and P12, either hot-finished or cold drawn, may be given a final heat treatment at 1200°F[650°C] to 1300°F [705°C] instead of heat treatments.

A335 steel pipe, specifically ASTM A335, is one of the most commonly used high-temperature resista nt steel pipes mainly due to its unique properties and broad range of applications. Here are a few reasons why A335 steel pipes are popular for high-temperature applications:

- Excellent mechanical properties: ASTM A335 steel pipes are made from ferritic alloy steels, which provide a good balance of strength, ductility, and toughness. This makes them suitable for high-temperature applications in industries such as power generation, petrochemical, and oil and gas.

- High-temperature resistance: A335 pipes are designed specifically for high-temperature service. They can withstand high temperatures without losing their mechanical properties, making them suitable for use in power plants, boilers, and heat exchangers, among other applications.

- Corrosion resistance: The alloying elements in A335 steel pipes, such as chromium and molybdenum, help to improve their resistance to corrosion, particularly in high-temperature environments. This makes A335 pipes suitable for applications where corrosion resistance is essential.

- Wide range of grades: ASTM A335 covers multiple grades of alloy steel pipes, each with unique chemical compositions and mechanical properties. This variety allows engineers to select the most appropriate grade for the specific application, temperature, and pressure requirements.

- Adaptability: A335 steel pipes can be manufactured in various sizes, thicknesses, and lengths, making them adaptable to a wide range of high-temperature applications.

- Industry standards: ASTM A335 is a widely recognized industry standard, which ensures that the pipes meet the necessary quality and performance requirements. This standardization simplifies the process of selecting and specifying steel pipes for high-temperature applications.

Overall, the combination of excellent mechanical properties, high-temperature resistance, corrosion resistance, adaptability, and industry standardization makes A335 steel pipes a popular choice for high-temperature applications in various industries.

2 comments

Pingback: Heavy Thick Steel Pipe » Stainless Steel & Alloy Steel Pipes | 2PE 3PE coated pipe | Pipe Fittings - Pipeline Technology R&D Factory

Ronsun2023

2025年3月28日 at pm9:37

From 2.875-inch to 26-inch OD and from . 375-inch to 4-inch wall thicknesses – and everything in between – Specialty Pipe & Tube’s got your heavy wall steel pipe and mechanical tubing needs covered.