ASTM A213 Alloy steel pipe, SA213 heat-exchanger tubes

ASTM A213 T2 T5 T5b T9 T91 Alloy Tubes Manufacturers

Abter steel offers high quality of ASME SA213, ASTM A213 T2 T5 T5b T9 T91 heat exchanger seamless steel tube to customers across the globe. In addition to supplying T2 T5 T5b T9 T91 alloy steel tubes, Metallica also offers fabrication services that include cutting, bending, shearing, saw cutting and welding for all of kinds of seamless steel pipes and tubes. Our primary objective is to ensure that our customers receive A213 T2 T5 T5b T9 T91 tubes at competitive prices, together with excellent service.

Features of ASTM A213 T2 T5 T5b T9 T91 Alloy Steel Heat Exchanger Tubes

T2 T5 T5b T9 T91 seamless alloy tubes shall be delivered in fully killed, and either as hot-finished or cold finished product.

Heat treatment is carried out separately and in addition to hot forming.

Flattening Test – One flattening test shall be made on specimens from each end of one finished tube, not the one used for the flaring test, from each lot.

Flaring Test – One flaring test shall be made on specimens from each end of one finished tube, not the one used for the flattening test, from each lot.

Hydrostatic or Nondestructive Electric Test – Each tube shall be subjected to the nondestructive electric test or the hydrostatic test. The type of test to be used shall be at the option of the manufacturer, unless otherwise specified in the purchase order.

A213 / SA213 Alloy Steel Pipe: Properties, Applications, and Advantages

A213 (ASME SA213) is a specification for seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes. These tubes are commonly used in high-pressure and high-temperature applications, such as power plants, petrochemical plants, and refineries. In this article, we will explore the properties, applications, and advantages of A213 / SA213 alloy steel pipes.

Table of Contents

- Introduction

- Grades and Composition

- Mechanical Properties

- Heat Treatment

- Applications

- Advantages

- Conclusion

1. Introduction

ASME SA213 is a specification that covers seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes. The tubes are made to custom sizes and can be used in high-pressure and high-temperature applications, such as power plants, petrochemical plants, and refineries.

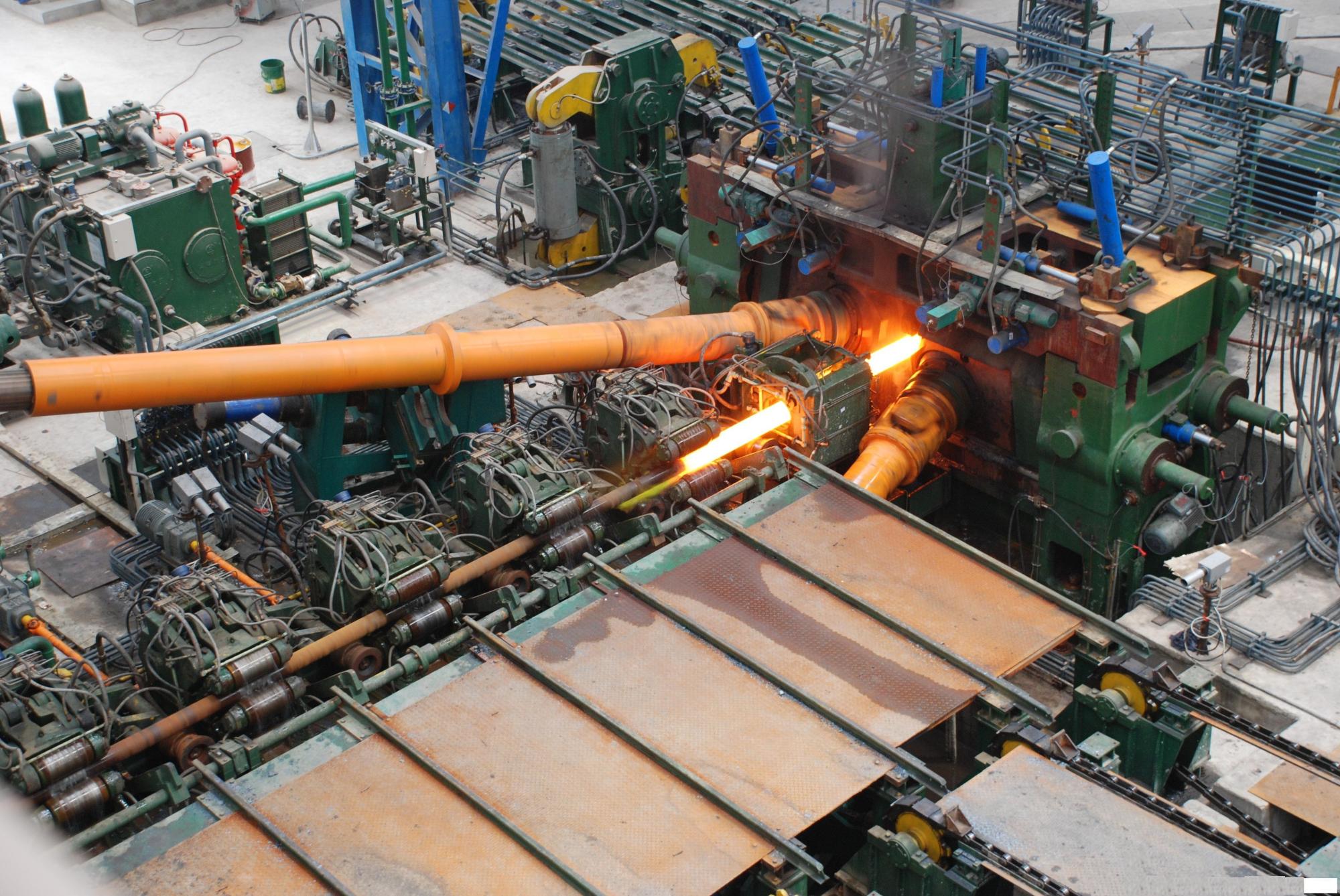

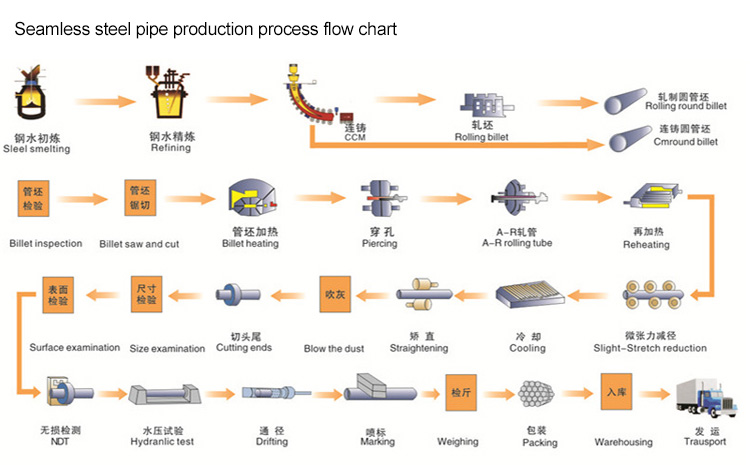

ASTM A213 / A213M ASME SA213 tubes shall be made by the seamless process and shall be either hot-finished or cold finished as specified.

ASTM A213 / A213M covers several grades of minimum- wall-thickness, seamless, alloy-steel, boiler and superheater tubes.

ASTM A213 / A213M tubing sizes and thicknesses usually furnished to this specification are 1⁄8 in. [3.2 mm] in inside diameter to 5 in. [127 mm] in outside diameter and 0.015 to 0.500 in. [0.4 to 12.7 mm], inclusive, in minimum wall thickness or, if specified in the order, average wall thickness. Tubing having other diameters may be furnished, provided such tubes comply with all other requirements of this specification.

2. Grades and Composition

The A213 / SA213 specification covers several grades of alloy steel, each with different chemical compositions. Some common grades include T5, T9, T11, T22, T91, and TP316, among others. The composition of each grade varies, but they generally contain elements such as chromium, molybdenum, and nickel, which provide improved high-temperature strength, corrosion resistance, and oxidation resistance.

Here is a brief overview of the chemical composition of some common A213 / SA213 alloy steel pipe grades:

| Grade | Chromium (Cr) | Molybdenum (Mo) | Nickel (Ni) | Other Elements |

|---|---|---|---|---|

| T5 | 4.00 – 6.00% | 0.45 – 0.65% | – | – |

| T9 | 8.00 – 10.00% | 0.90 – 1.10% | – | – |

| T11 | 1.00 – 1.50% | 0.44 – 0.65% | – | – |

| T22 | 2.00 – 2.50% | 0.87 – 1.13% | – | – |

| T91 | 8.00 – 9.50% | 0.85 – 1.05% | – | Nb, V, N |

| TP316 | 16.00 – 18.00% | – | 10.00 – 14.00% | Mo, Mn, Si, P, S, C |

3. Mechanical Properties

The mechanical properties of A213 / SA213 alloy steel pipes depend on the specific grade and heat treatment. Here are some typical mechanical properties of common grades:

| Grade | Tensile Strength (min) | Yield Strength (min) | Elongation (min) |

|---|---|---|---|

| T5 | 60 ksi (415 MPa) | 30 ksi (205 MPa) | 30% |

| T9 | 60 ksi (415 MPa) | 30 ksi (205 MPa) | 30% |

| T11 | 60 ksi (415 MPa) | 30 ksi (205 MPa) | 30% |

| T22 | 60 ksi (415 MPa) | 30 ksi (205 MPa) | 30% |

| T91 | 85 ksi (585 MPa) | 60 ksi (415 MPa) | 20% |

| TP316 | 75 ksi (515 MPa) | 30 ksi (205 MPa) | 35% |

| Grade | Tensile strength | Yield point(Mpa) | Elongation(%) | Impact(J) | Hardness |

| (Mpa) | not less than | not less than | not less than | not less than | |

| A213 T2/SA213 T2 | ≥415 | 205 | “ | 85HRB | |

| A213 T11/SA213 T11 | ≥415 | 205 | “ | 85HRB | |

| A213 T22/SA213 T22 | ≥415 | 205 | “ | 85HRB | |

| A213 T23/SA213 T23 | ≥510 | 400 | 20 | “ | 97HRB |

| A213 T24/SA213 T24 | ≥585 | 415 | 20 | “ | 25HRB |

| A213 T91/SA213 T91 | ≥585 | 415 | 20 | “ | 25HRB |

| A213 T911/SA213 T911 | ≥620 | 440 | 20 | “ | 25HRB |

| A213 T22/SA213 T92 | ≥620 | 440 | 20 | “ | 25HRB |

| A213 T122/SA213 T122 | ≥620 | 400 | 20 | 25HRB | |

| TP304H | ≥515 | 205 | 35 | 90HRB | |

| TP316H | ≥515 | 205 | 35 | 90HRB | |

| TP321H | ≥515 | 205 | 35 | 90HRB | |

| TP347H | ≥515 | 205 | 35 | 90HRB | |

| S30432 | ≥590 | 235 | 35 | 95HRB | |

| TP310HCbN | ≥655 | 295 | 30 | 100HRB |

Note:

A Maximum, unless range or minimum is indicated. Where ellipses (…) appear in this table, there is no requirement, and analysis for the element need not be determined or reported.

B It is permissible to order T2 and T12 with a sulfur content of 0.045 max. See 16.3.

C Alternatively, in lieu of this ratio minimum, the material shall have a minimum hardness of 275 HV in the hardened condition, defined as after austenitizing and cooling to room temperature but prior to tempering.

Hardness test frequency shall be two samples of product per heat treatment lot and the hardness testing results shall be reported on the material test report.

4. Heat Treatment

A213 / SA213 alloy steel pipes undergo heat treatment to achieve the desired mechanical properties, corrosion resistance, and hardness. The specific heat treatment depends on the grade and may include normalizing, quenching, and tempering. For example, T91 grade pipes are typically normalized at 1040°C (1900°F), quenched in water or oil, and tempered at 760°C (1400°F).

5. Applications

A213 / SA213alloy steel pipes are used in a wide range of applications due to their high-temperature strength, corrosion resistance, and excellent mechanical properties. Some typical applications include:

- Power plants: boiler tubes, superheater tubes, and heat-exchanger tubes

- Petrochemical plants: high-pressure and high-temperature process piping

- Refineries: high-temperature and high-pressure systems for crude oil processing

- Oil and gas industry: pipelines and heat exchangers in high-pressure and high-temperature environments

- Chemical processing plants: high-temperature and high-pressure piping systems

- Fossil fuel and nuclear power stations: steam generation and heat transfer equipment

6. Advantages

Some of the key advantages of using A213 / SA213 alloy steel pipes include:

- High-temperature strength: suitable for applications involving high temperatures and pressures

- Corrosion resistance: resistance to various forms of corrosion, including oxidation and stress-corrosion cracking

- Excellent mechanical properties: high tensile strength, yield strength, and elongation

- Customizability: available in various grades, sizes, and wall thicknesses to meet specific application requirements

- Heat treatment: can be heat-treated to achieve the desired mechanical properties and hardness

7. Conclusion

In conclusion, A213 / SA213 alloy steel pipes are a popular choice for various high-temperature and high-pressure applications due to their excellent mechanical properties, corrosion resistance, and customizability. The availability of different grades and heat treatment options allows these pipes to be used in a wide range of industries, including power plants, petrochemical plants, refineries, and the oil and gas industry. With their numerous advantages, A213 / SA213 alloy steel pipes provide reliable and durable solutions for various challenging applications.

ASTM A213M-09 Material Comparison Tables (ASTM →KS, JIS, DIN, BS, NBN, NF, UNI)

| Grade | UNS Designation | C | Mn | P | S | Si |

| T2 | K11547 | 0.10–0.20 | 0.30–0.61 | 0.025 | 0.025B | 0.10–0.30 |

| T5 | K41545 | 0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.5 |

| T5b | K51545 | 0.15 | 0.30–0.60 | 0.025 | 0.025 | 1.00–2.00 |

| T5c | K41245 | 0.12 | 0.30–0.60 | 0.025 | 0.025 | 0.5 |

| T9 | K90941 | 0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.25–1.00 |

| T11 | K11597 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.50–1.00 |

| T12 | K11562 | 0.05–0.15 | 0.30–0.61 | 0.025 | 0.025B | 0.5 |

| T17 | K12047 | 0.15–0.25 | 0.30–0.61 | 0.025 | 0.025 | 0.15–0.35 |

| T21 | K31545 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.50–1.00 |

| T22 | K21590 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.5 |

| T23 | K40712 | 0.04–0.10 | 0.10–0.60 | 0.03 | 0.01 | 0.5 |

| T24 | K30736 | 0.05–0.10 | 0.30–0.70 | 0.02 | 0.01 | 0.15–0.45 |

| T36 | K21001 | 0.10–0.17 | 0.80–1.20 | 0.03 | 0.025 | 0.25–0.50 |

| T91 | K90901 | 0.07–0.14 | 0.30–0.60 | 0.02 | 0.01 | 0.20–0.50 |

| T92 | K92460 | 0.07–0.13 | 0.30–0.60 | 0.02 | 0.01 | 0.5 |

| T122 | K91271 | 0.07–0.14 | 0.7 | 0.02 | 0.01 | 0.5 |

| T911 | K91061 | 0.09–0.13 | 0.30–0.60 | 0.02 | 0.01 | 0.10–0.50 |

| Grade | UNS Designation | Vana- | Boron | Niobium | Nitrogen | Aluminum | Tungsten |

| dium | |||||||

| T2 | K11547 | … | … | … | … | … | … |

| T5 | K41545 | … | … | … | … | … | … |

| T5b | K51545 | … | … | … | … | … | … |

| T5c | K41245 | … | … | … | … | … | … |

| T9 | K90941 | … | … | … | … | … | … |

| T11 | K11597 | … | … | … | … | … | … |

| T12 | K11562 | … | … | … | … | … | … |

| T17 | K12047 | 0.15 | … | … | … | … | … |

| T21 | K31545 | … | … | … | … | … | … |

| T22 | K21590 | … | … | … | … | … | … |

| T23 | K40712 | 0.20–0.30 | 0.0010–0.006 | 0.02–0.08 | 0.015 | 0.03 | 1.45–1.75 |

| T24 | K30736 | 0.20–0.30 | 0.0015–0.007 | … | 0.012 | 0.02 | … |

| T36 | K21001 | 0.02 | … | 0.015–0.045 | 0.02 | 0.05 | … |

| T91 | K90901 | 0.18–0.25 | … | 0.06–0.10 | 0.030–0.07 | 0.02 | … |

| T92 | K92460 | 0.15–0.25 | 0.001–0.006 | 0.04–0.09 | 0.030–0.07 | 0.02 | 1.5–2.00 |

| T122 | K91271 | 0.15–0.30 | 0.0005–0.005 | 0.04–0.10 | 0.040– | 0.02 | 1.50–2.50 |

| T911 | K91061 | 0.18–0.25 | 0.0003–0.006 | 0.06–0.10 | 0.040–0.09 | 0.02 | 0.90–1.10 |